What is needed to insulate the floor? How to inexpensively insulate a floor in a private house: Description of insulation materials and tips for choosing. Comes in four varieties

After building a house, in order to retain heat, floor insulation will be required, especially if we are talking about wooden building. It is necessary to prevent the penetration of cold coming from the ground, or from basement. Before you choose technological process When insulating a floor with your own hands, you need to choose a material based on the characteristics of the base to be insulated.

Now there are a lot of insulated insulation materials on the market, and high-tech ways to retain heat are appearing every day. To understand the best way to insulate a floor, let’s look at the types of insulators.

The most popular are:

- Styrofoam;

- expanded polystyrene;

- glass wool;

- expanded clay;

- mineral wool;

- penofol or isolon;

- cork insulation materials;

- ecowool consisting of cellulose;

- fiberglass or gypsum fiber;

- “Thermo Plast” – bulk material;

- foam glass;

- stone wool;

- linen in mats;

- slag;

- polyurethane foam.

These insulators are divided into synthetic and natural. Natural – ecowool, cork, sawdust, flax. The rest are synthetic.

Floor insulation material is divided into types:

- bulk– sawdust, expanded clay, slag, foam glass;

- aspic – polymer compositions, applied by pouring;

- sprayed– polyurethane;

- in the form of slabs– penoplex, mineral wool, flax in mats, gypsum fiber layers, glass wool, polystyrene foam, stone wool;

- roll– penofol, cork, isolon, flax, linoleum with an insulating layer.

The technology that will be used for thermal insulation directly depends on the type of insulation chosen. If expanded clay or penoplex is chosen as an insulator, then you will have to install logs or arrange a screed.

Rolled cork insulation, or isolon, can simply be rolled out over the surface and closed on top facing material such as parquet, laminate, or railcar. As for linoleum with an insulating layer, there is no need to lay insulating material

, it itself is a good insulator.

If the height of the room is small, then it is better to use a self-leveling heat insulator, which will take the minimum height. If we consider bulk or slab insulators, then it is worth remembering that they will take up about 5-10 cm in height. It is possible to apply thermal insulation using logs, or on the ground, this makes it possible to use thick slab or roll insulation.

As for the apartment, it is better to use thin materials, since the ceiling height in apartments is usually 2.5 meters.

Before choosing a heat insulator, it is worth assessing the humidity of the room and measuring its height.

The higher the ceiling height, the wider the choice of insulators that can be used for floor insulation.

You can get 100% insulation by using an electric heated floor in combination with isolon; in this case, you can regulate the temperature of the floor covering by switching the heating power.

How to properly insulate a floor, there are several insulation methods that are used to insulate a floor depending on the type of base - it can be wood, soil and concrete.

Floor insulation on the ground When building a house, many private developers save on insulation by pouring concrete screed straight to the ground, and this is not entirely correct. Firstly, the ground can freeze in winter, and concrete covering

will be cold, and secondly, the screed will be in contact not only with the ground, but also be exposed to bottom waters, which will quickly disable it. Therefore, it is important to carry out high-quality waterproofing and insulation of the floor on the ground.

It is advisable to carry out insulation of the floor on the ground only if the bottom waters are at a sufficient depth from the surface. Otherwise, it is better to install beams and double flooring with insulation. The insulation of the floor on the ground is carried out during the construction process; the finished covering will have to be dismantled, which will lead to the waste of additional funds. The floor pie begins to be formed after the foundation of the building has completely dried.

It is worth noting that the latter structure should rise 20 cm above the ground.

- Several layers should be arranged:

- directly the soil;

- coarse river sand to level the surface;

- waterproofing layer;

- thermal insulation material;

- mesh, chain-link, for reinforcement;

screed

The first insulation option

- Let’s take a closer look at how to properly insulate a floor over the ground:

- The soil under the house needs to be leveled, debris and weeds removed, recesses filled and the entire surface compacted well. Cover the entire surface river sand

- Lay a layer of waterproofing; for this you can use:

- polymer-based membrane material;

- roofing felt;

- polyethylene film 200 microns, in two folds - the most cheap option waterproofing.

- After this, you can begin laying the slab heat-insulating material - this can be expanded polystyrene or polystyrene foam.

- Then you can start pouring finishing screed, just lay down the reinforcing mesh before doing this.

Second insulation option

A better quality one, although it will cost more, is being built for this purpose. rough screed, on which the waterproofing is placed - for the sake of economy - polyethylene film.

It needs to be pressed against the foundation with bars, and the material should extend onto the walls no less than 15 cm. An insulated floor in this way has very good thermal insulation characteristics.

- As soon as the waterproofing is ready, insulation is laid, for example:

- expanded clay;

- penoplex;

Styrofoam.

These are cheap types, but they are good heat insulators.

How to insulate a floor in a wooden building?

At the stage of building a house, the process of insulating the floor begins. First of all, the area under the floor is covered with sand to a depth of 5-6 cm, then expanded clay is poured onto it. When choosing insulation, you need to take into account many points, for example, if you choose natural materials

, then it is worth remembering that they are susceptible to burning, and rarely resist moisture, and various microorganisms and rodents can grow in them.

Sawdust and cellulose, treated for fire safety, are often used to insulate the base.

- As for slab insulation, the following are considered in demand and of high quality:

- expanded polystyrene;

- glass wool;

- mineral wool;

dry screed.

The finished floor is mounted on joists, with insulation installed in the gaps. The finishing coating can be installed over the screed. The screed is additionally insulated with expanded clay. How to insulate the floor along the joists? To do this, the structure is assembled in increments of 40 -60 cm, while the subfloor must be well waterproofed from below. A vapor barrier is laid on top of the boards and joists. After this, insulating slab material is placed in the gaps, the width of the slabs is exactly 60 cm, and the fine coating

– plywood, OSB or board. If during construction it is decided to pour a rough screed, then it is better to do it using expanded clay.

If the floor in the house is wooden, then dry screed on the floor is well suited for insulation. To install such insulation, you need to fill the expanded clay along the leveled guides. Then slab gypsum fiber insulation is laid on the expanded clay. This method is simple, but not applicable when high humidity.

Not long ago, a practical, durable and fireproof material appeared on the market - foam glass. The thickness of this material reaches 12 cm. These slabs can be laid not only on a wooden floor, but also on a concrete one.

How to insulate a concrete floor

Concrete floors can be insulated with the following materials:

- expanded polystyrene;

- Styrofoam;

- ecowool;

- liquid insulation;

- mineral wool.

But this heat insulator will take away precious centimeters from the height of the room, since logs need to be mounted on top of the base, on top of which you will have to lay plywood or OSB, and only then the finishing flooring. At the same time, this is a very labor-intensive process and very expensive.

You can arrange a screed by combining it with polystyrene foam. In this case, pipes for heated floors can be installed into the screed - the thickness of the coating will be more than 10 cm.

You can arrange a pie from expanded clay and gypsum fiber board, then the thickness of the thermal insulation will be 7 centimeters. If the base is initially flat, then only gypsum fiber sheets can be used, and the thickness of the insulation will be only 2 cm. When insulating the floor in an apartment with not very high ceilings, it is not advisable to choose thick insulation, since it will reduce usable space for life.

If the floor in the apartment requires insulation, then it is better to use isolon followed by the installation of a warm, infrared, or electric floor.

This option will not reduce the height, and will make living in the apartment more comfortable, due to the fact that the floor temperature can be adjusted. The most effective option

for high ceiling heights, install a water-heated floor. The height of the coating in this case will be 10-12 cm. To save space, you can use a screed with an insulating effect. This is enough new material

, but has already proven itself to be of high quality and reliable. In this case, the insulation layer will be only 3 cm. You can use the simplest and most common method - double flooring. Boards 2.5 cm thick are fixed directly onto the concrete base with tongue and groove. After this, wooden base

lay the substrate and laminate, or linoleum with an insulating layer. Linoleum on a backing is often used directly on a concrete base, while thermal insulation properties

Fiberglass or wood can be laid on top of this insulation. Some people lay a finished floor covering directly on polyurethane foam in order to save money.

In custody

Insulating the floor in a room - each master has his own method. Some people prefer time-tested materials, making a thermal insulation “pie” out of them. Some people prefer innovative thermal insulators. But the main factor when choosing a material is the cost and quality of floor insulation.

Concrete floors are the most practical option for a private home, thanks to its strength, durability and low costs for production. But concrete is a cold material, and without high-quality thermal insulation In winter the house is not very comfortable. In addition to high heat loss, condensation, which forms due to the large temperature difference on the inside and outside of the concrete base, also creates problems. There are several ways to insulate a concrete floor in a private house, and even a novice master can do all of them.

Concrete floors can be insulated in three different ways:

- simplest - lay insulation on concrete surface continuous layer. To do this, the base is cleaned of dust, unevenness is eliminated, and, if necessary, filled with leveling mixtures. The insulation can be attached with glue, dowels, or a combined method, after which the finishing coating is installed. Individual insulation materials themselves act as finished floor coverings, which reduces installation time and saves a little money;

- frame method - logs are first installed on a concrete base, then the space between them is filled with insulation, and a finished floor is laid. The method is more labor-intensive, but allows the use of materials with a lower density that cannot withstand high loads;

- laying insulation under the screed - mounted on concrete floor a layer of thermal insulation and poured on top cement-sand mortar , resulting in the formation of a monolithic, solid base. The method is the most labor-intensive and time-consuming, but this base is perfect for any floor covering - from linoleum to tiles. In addition, this option is used when installing electric and water heated floors, which ensures uniform heat transfer over the entire area of the room.

When choosing, the determining criterion is the type of flooring and the method of its installation. For example, soft and roll materials, since they are not designed for high loads. The same applies to insulation materials laid directly under the finishing coating: they must have good density and rigidity so as not to be pressed through during operation. It is also worth considering that logs and insulated screed take up to 15 cm in height, so for rooms with low ceilings the first installation method is preferable.

Selection of insulation materials for concrete

The insulation market now provides wide choose materials of both domestic and foreign production. For thermal insulation of concrete floors, particle boards are most often used. fibrous materials, plates made of foamed polymers. Sprayed insulation, which is applied using special equipment, is also gaining popularity. Among inexpensive options For a private home, it is worth noting expanded clay - a natural, environmentally friendly material with excellent heat-insulating properties.

The key characteristics of insulation are:

- density– the higher this indicator, the large quantity heat will be retained;

- strength– determined by bending and compression. The higher the expected loads, the stronger the insulation should be;

- thermal conductivity– the efficiency of heat conservation in the room depends on this indicator. Preference should be given to materials with the lowest thermal conductivity coefficient;

- moisture permeability– the higher the indicator, the faster the thermal insulation properties of the material deteriorate. Insulation saturated with water is not able to retain heat, so it will have to be replaced;

- durability– in order to save money, it is worth choosing a material with the longest service life, because frequent replacement of insulation and accompanying repairs are expensive;

- environmental friendliness– in residential premises it is necessary to use only environmentally friendly insulation, since the floor covering is not a good protection against toxic fumes.

The weight of the material does not play a big role, because, unlike a city apartment, there is no need to worry about increased loads on the floors between floors.

So let's consider popular insulation materials, their properties, pros and cons.

| Material | Main characteristics |

|---|---|

| It has low thermal conductivity and perfectly muffles sounds. Available in rolls and slabs, differing in density. It does not burn, but has high moisture permeability, and therefore requires high-quality waterproofing during installation. The service life, subject to installation technology, is 25-30 years. Insulation with mineral wool is carried out only along logs, since the material cannot withstand high loads |

| They have good strength and heat capacity, have soundproofing characteristics, and can be laid directly on concrete or on logs. For floor insulation, slabs with a thickness of at least 20 mm are suitable. Moisture resistance is average, so wet grounds waterproofing required. In dry rooms, the material can be laid directly on concrete, pre-treated with a primer |

| This group includes polystyrene foam and EPS. They are lightweight, easy to install, and have very low thermal conductivity. They can be laid under a screed or between joists, and EPS can also be laid on the concrete floor itself. Polystyrene foam is cheaper, but less durable, so if there are increased requirements for floor construction, it is better to use extruded polystyrene foam. Foam insulation is resistant to moisture and lasts on average from 20 to 30 years |

| They form a seamless durable coating with low thermal conductivity and moisture resistance. They are used for insulating concrete along joists. Such thermal insulation is one of the most reliable and durable, but it is also much more expensive than other materials. This is due to the need to use special installation, with the help of which spraying is carried out |

| Most environmentally friendly insulation By affordable price. Used for insulation along joists and under screeds. To ensure maximum thermal insulation, the material should be covered with a thick layer - from 10 to 20 cm. Expanded clay does not burn, it has long term operation, but at the same time it is very fragile and loses its thermal insulation properties due to structural damage |

| Lightweight, environmentally friendly insulation with water-repellent properties. Cork has a very low thermal conductivity, it is always warm to the touch, so it is ideal not only as a substrate, but also as an independent floor covering. It can be laid directly on a concrete floor, painted or varnished. The only disadvantage of insulation is the high price |

There is another type of insulation that appeared not so long ago and has not yet gained widespread popularity. This liquid thermal insulation– new generation material with unique properties. Looks like a thick white paint, and is applied in the same way, forming an elastic, durable coating. A layer of 1 mm can replace roll thermal insulation 50 mm thick, in addition, this coating is impervious to moisture, chemical attack, does not burn and does not emit toxic substances. This paint is used not only for insulating concrete floors, but also for walls, slopes, pipelines, facades, and various containers. The coating lasts for about 15 years if applied correctly.

Liquid thermal insulation coating "Astratek"

We insulate a concrete floor with our own hands

Before insulation, the concrete surface must be inspected and all defects eliminated. This applies to potholes, cracks, and crumbled areas. Small differences in height are leveled with leveling mixtures. This preparation is a mandatory step and ensures the reliability and durability of the floor. Now let’s look separately at the most popular methods of insulating a concrete floor in a private house.

Insulation with polystyrene foam

To work you should prepare:

- Eps boards;

- waterproofing film;

- damper tape;

- vapor barrier membrane;

- construction tape;

- gypsum fiber sheets;

- GVL glue;

- tools and fasteners.

The surface of the concrete floor must be clean, absolutely dry and not have differences in height of more than 5 mm.

Step 1. The floor is covered with a waterproofing film, the sheets of which are overlapped by 10-15 cm, and the joints are secured with tape. To increase sound insulation, you can lay a second layer of geotextile fabric with a density of 300 g/m2.

Advice. Waterproofing is mandatory for bathrooms, kitchens and other rooms with high humidity; in other rooms, insulation can be laid directly on a concrete base.

Step 2. A damper tape is laid around the perimeter of the room so that its bend falls exactly at the junction between the wall and the floor.

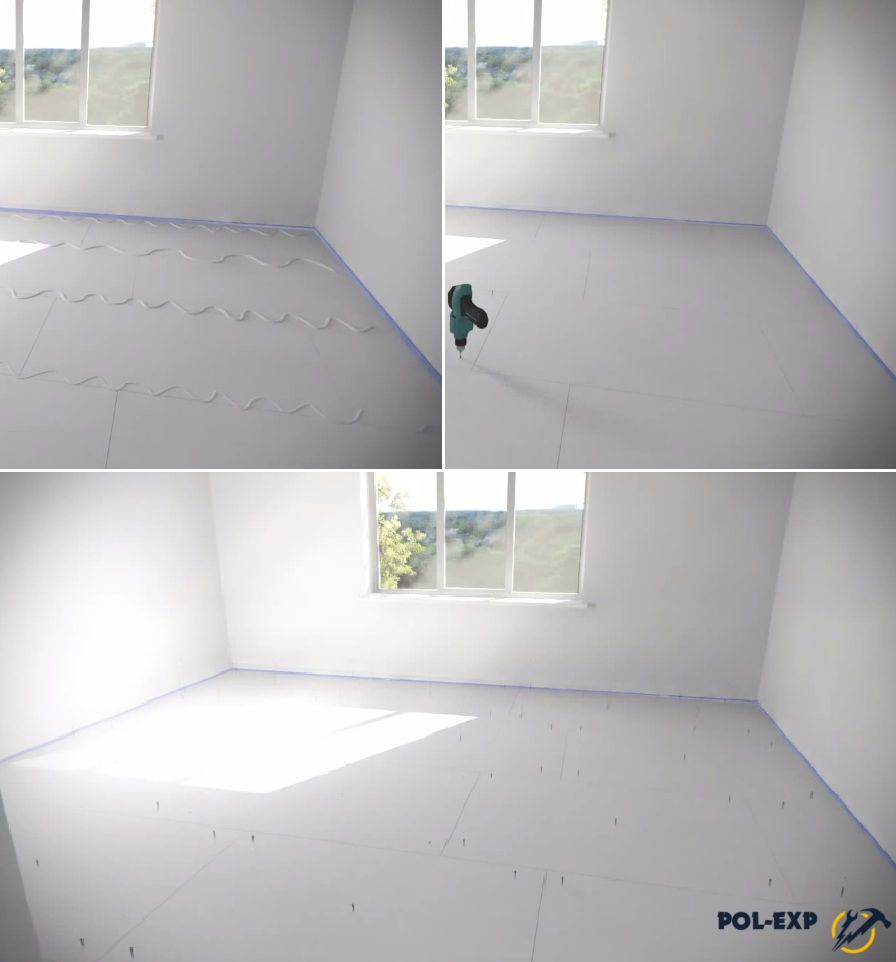

Step 3. The first row of polystyrene foam is laid. The slabs fit tightly together using grooves and ridges on the side edges. The last slab in the row is trimmed if necessary.

Step 4. The insulation must be laid with offset seams, staggered, so the second row begins with a cut slab. Everything else is exactly the same: EPPS is laid joint-to-joint, leveled, making sure that all the slabs are located in the same plane.

Step 5. A vapor barrier membrane is laid on top of the polystyrene foam. Its canvases are also overlapped, the edges are placed on the wall to a height of 10 cm, all joints are sealed with tape.

Step 6. A prefabricated screed is installed. Gypsum sheets are laid on the floor joint to joint in a checkerboard pattern. Next, glue is applied along the seams between the rows in continuous wavy stripes and the second one is laid GVL layer so that the seams are completely covered by the sheets.

Step 7 When the glue hardens, both layers are mechanically fixed to each other. Self-tapping screws are screwed into each sheet in the corners and in the center, slightly recessing the fastener heads into the material.

After this, you can lay any finishing coating and even install a warm floor under the tiles. Heating elements can be located both in the screed layer and in the tile adhesive layer.

Insulation with mineral wool on joists

To work you will need:

- mineral wool in slabs or rolls;

- waterproofing film;

- wooden beam for logs;

- plywood or chipboard for flooring with a thickness of 18 mm;

- dowels and screws;

- tape measure, level and mounting knife;

- drill and hammer drill.

Step 1. Concrete base cover with a layer waterproofing film. Adjacent canvases should be overlapped by 15-200 cm, the joints taped.

Step 2. Logs with a cross-section of at least 110x60 mm are installed on top of the film. The distance between the logs depends on the thickness of the floor covering; in this case, it is recommended to take a step of about 300 cm. The timber is placed on an edge, be sure to control the plane with a level, and also make sure that the logs are positioned strictly parallel to each other.

Step 3. Screw the logs to the base. To do this, drill them through and go deep into the base by 50-60 mm. Next, insert the dowels and screw in the screws. The fastening pitch is 40-50 cm.

Advice. To fix the joists to the floor experienced craftsmen It is recommended to use screws whose threads do not reach the head. Such fasteners allow you to tighten the beam more tightly to the base.

Step 4. Install insulation. A roll of mineral wool is rolled out over the joists, after which the insulation is cut into strips so that each of them tightly fills the space between the beams. If used slab insulation, the slabs are alternately inserted between the lags, spaced apart, and, if necessary, cut to width. The joists should protrude above the insulation by approximately 20 mm.

Step 5. The next stage is laying the subfloor. The plywood is cut out and the sheets are laid end to end in a continuous layer. You can use tongue and groove slabs with protective moisture-resistant coating. The material is laid with its long side perpendicular to the joists and attached to the frame with self-tapping screws at 20 cm intervals. The rows of slabs are laid with offset seams, and the joining of the seams in the row is carried out along the longitudinal axis of the joists.

Before laying the slabs, the adhesive is applied to the ends with a brush, which ensures a high degree of moisture resistance.

To provide greater protection to the insulation from moisture, before installing the flooring, it is recommended to lay a vapor barrier membrane with an overlap of strips of at least 10 cm. You can also glue the joints of the slabs during installation, ensuring complete tightness of the subfloor. After this, all that remains is to lay the finishing coating and secure the baseboards.

Prices for Rockwool mineral wool

rockwool mineral wool

Prepare everything you need in advance:

- polystyrene foam boards;

- reinforcing mesh;

- profile for beacons;

- rule;

- glue;

- damper tape;

- cement and sand for mortar.

Step 1. The concrete floor is thoroughly cleaned of dust and debris. Damper tape is glued around the perimeter of the room.

Step 2. Take the first insulation board, apply glue with a spatula in the center and in the corners, lay it on the floor and press it with your hands over the entire surface. The next plate is fastened end-to-end with the first, pressing tightly along the seam. In the same way, lay the whole thing to the end, if necessary, trimming the outer slab.

Step 3. The first slab of the second row is cut to create an offset joint installation. Further installation is carried out in the manner described above. If a second layer of insulation is required, the top slabs are placed so that they completely overlap the seams in the bottom layer.

Step 4. A reinforcing mesh of metal rods is laid on top of the insulation. There should be a distance of 20-30 mm between the edges of the mesh and the walls.

Advice. Before laying the mesh, it is recommended to cover the insulation with a thick plastic film, taping the joints of the strips with tape. This is not necessary to protect the insulation from moisture (expanded polystyrene is moisture-resistant material), but in order to avoid leakage of the solution into the joints between the slabs and the formation of air voids in the screed.

Step 5. Profile beacons are laid on the reinforcing mesh and fixed with a small amount of solution. Here it is very important to set the beacons at the level, because the evenness of the floor depends on this. All beacons must be strictly horizontal and in the same plane.

Step 6. Mix the solution and pour it between the beacons. Next, using the rule, the mixture is stretched along the beacons and leveled. If grooves form, more mortar must be added. The thickness of the screed is made within 4-6 cm.

After leveling the surface, the screed is left to dry. When the solution has set well, you should carefully remove the beacons and seal the grooves with fresh cement mixture.

While the floor is drying, it must be protected from direct sun rays and drafts, and periodically moisten the first 10 days so that the screed does not crack.

For comfortable living conditions, a person needs an optimal temperature in the living space. Insulation is becoming an integral part of construction work in a private house. Only those people who have a high-quality foundation under their house or ground floor. In other cases, it is necessary to insulate the floor in a private house with your own hands.

Most floor insulation technologies will not take much time, and given the opportunity to do the work yourself, floor insulation in wooden house allows you to save not only on construction work, but also on heating costs.

The easiest way to have a beautiful front lawn

Of course you saw perfect lawn in the cinema, on the alley, and perhaps on the neighbor’s lawn. Those who have ever tried to grow a green area on their site will no doubt say that it is a huge amount of work. The lawn requires careful planting, care, fertilization, and watering. However, only inexperienced gardeners think this way; professionals have long known about the innovative product - liquid lawn AquaGrazz.

Materials for floor insulation

To insulate the floor in a private house you can use:

- expanded clay;

- Styrofoam;

- mineral wool;

- ecowool;

- As soon as the waterproofing is ready, insulation is laid, for example:

- isolon;

- penofol;

- wood concrete

We will tell you about the most popular and budget options.

Expanded clay

The most common insulation. This substance is sold in the form of granules and has a porous structure. Thanks to this it is very light. The main component for the manufacture of expanded clay is clay, and the material does not come into contact with water and does not change its properties. During the manufacturing process, the material becomes resistant to temperature changes. Its significant advantage is fire safety, which significantly expands its range of uses.

Expanded clay has proven itself in use as a strong and durable thermal insulation element. In addition, it has no impurities and is considered environmentally friendly clean material. It is easy to install - you just need to apply the material in a layer. This advantage easily turns into a disadvantage: if the layer is less than 10 centimeters, then the insulation will not work.

Styrofoam

This option is considered less expensive. Polystyrene foam is often used as insulation for both floor and wall surfaces. The material has a high coefficient of heat and sound insulation. Depending on the density, its functional ability changes. As it grows, so does its impact resistance. Polystyrene foam will serve as insulation for decades.

Among the disadvantages of polystyrene foam is toxicity; when burned, it emits a large amount of corrosive gases, and instability to the aquatic environment. At high humidity, the material will quickly become saturated with water and lose its heat-saving properties.

Mineral wool

Considering the shortcomings of the above materials, technologists invented the material highest quality. It's called mineral wool. It is an excellent insulator and has all the advantages of the previous options. The use of mineral wool is permissible both on walls and on ceilings and floors. Cotton wool is commercially available in the form of slabs and rolls. According to manufacturers, the material can not lose its properties for 30 years.

The advantages include good thermal conductivity and sound insulation. Cotton wool has good fire resistance and does not allow a fire source to spread quickly, which is why it is often used in wooden houses.

Important: the only drawback of this material appears during the production process. Since mineral wool is made using wooden base, it becomes susceptible to moisture, which entails heat loss.

The process of insulating a house with mineral wool requires preparation. The wool must be thoroughly waterproofed using a Barrier. It can be purchased in roll form. Cotton wool is susceptible to the influence of rodents, so it must be additionally protected.

Ecowool

As the name implies, the material is environmentally friendly. This is the next generation of mineral wool. Its composition includes up to 75% cellulose fibers, due to which the material has increased heat resistance. Like the previous option, cotton wool can get wet, but its structure allows it to quickly remove water, and after complete drying, all properties are restored, thanks to which ecowool retains precious heat even better.

In stores, such cotton wool can be found in two variations: ready-made blocks and mortar. Physical properties the second allows for better insulation hard to reach places: the material fills the entire space and seeps well into the cracks.

Important: the solution is used less frequently due to its price: it is very high.

Penoplex

Today the most popular insulation. The manufacturing process is similar to the production of polystyrene foam. At the initial stage, technologists mix the components and beat them. But ultimately, the material is compressed under heavy load, and its “balls” do not grow. The result is a durable material of a new generation.

It incorporates the advantages of all previous options. Even a child can handle the installation, and the material will not allow heat to pass through for several decades. In our area, penoplex has gained popularity due to its resistance to frost, which makes it possible to use it not only indoors, but also outdoors. Penoplex is able to retain heat in the house, even when its thickness does not exceed five centimeters, which cannot be achieved with masonry. At the same time, it does not absorb moisture at all.

However, penoplex has a number of disadvantages. Firstly, it is capable of not only burning, but also melting, which does not allow it to be used, for example, near a village stove. Secondly, it is quite expensive.

Izolon

Its uses are very diverse. Experienced builders apply it as initial stages construction, and at the time finishing works. No toxic materials are used in the production process, making izolon environmentally friendly. Moisture does not seep into such material, and therefore mold is eliminated. Izolon has fire-resistant properties. And the main advantage is its small thickness, which allows the material to be used almost under finishing. Builders compare the thermal permeability of a 20-mm layer of isolon with a whole brick wall.

Penofol

Serves as a substitute for isolon and is presented in the form of puff pastry. Each layer performs a specific function, which makes the material warmer with a smaller thickness. Each sheet contains:

- Foil layer for protection from moisture and steam;

- Foamed polyethylene as insulation.

Builders really liked the material due to its functionality. There are several types of penofol on the market, which significantly expands the range of uses. Depending on the purpose, its thickness and price vary. There is a special penofol that has an adhesive side. It is very easy to install a thermal insulation layer from it.

Arbolit

To create a durable and warm floor surface It is permissible to use wood concrete. This material is made from concrete and sawdust. It perfectly suppresses noise and is capable of high-quality thermal insulation of the room. Although it contains concrete, its weight is small. The material is susceptible to processing and subsequent work. It is completely non-flammable, but can become saturated with moisture, which significantly impairs its thermal insulation properties.

Important: in order to insulate the floor with wood concrete, it is necessary to vapor barrier all surfaces.

House insulation work

Let's consider the simplest insulation using polystyrene foam. For installation you will need:

- Styrofoam;

- vapor barrier;

- cement;

- sand;

- reinforcing mesh.

If the house does not have a subfloor, you should dig the earth crust to a depth of 15 centimeters or make a drainage embankment to the same height. Then the surface is leveled and a steam and hydrobarrier is laid. Sometimes you can limit yourself to simple film.

Next stage - rough finish floor.

Important: the cement layer must be at least four centimeters.

When laying foam boards, they must be carefully pressed: this will avoid cracks. After this, work stops for two days. This will allow the solution to bond.

After drying, the floor is finished. To ensure the floor is level, beacons are installed and a level is used.

When using expanded clay, the procedure is the same. However, do not forget about the thermal conductivity of expanded clay, so it is necessary to pour it in a high layer - from ten centimeters. After pouring the finishing layer, it is advisable to leave the room for the next week until the solution dries completely.

Expanded clay is successfully used for insulating houses on logs. In this case, you only need to fill in the material, and you can begin to close the floor.

Insulation of a floor installed on joists includes several stages:

- Removing the floor (if necessary);

- Removing the top layer or digging a trench;

- Laying waterproofing;

- Laying thermal insulation;

- Another layer of waterproofing;

- Installation of flooring.

The steps may vary depending on the material selected. The log method is a simpler and less labor-intensive option. The only question is the foundation of the house, or rather, its availability.

Often used as a subfloor reinforced concrete slabs. In this case the best option mineral wool or its equivalent is used for insulation. And to give strength to the material, it is advisable to use a concrete screed. The cotton wool will need to be previously covered with mounting tape or film.

A comfortable atmosphere in a private home depends on many factors. However, on comfortable temperature affects the house and apartment high-quality insulation all designs. The most important indicator can be considered the floor temperature in the room. It is worth saying that if you produce proper insulation floors in your home, you can make your stay in your home enjoyable. Besides, good thermal insulation Flooring will allow you to reduce heating costs for your home many times over. Therefore, today the construction portal will talk about how to insulate the floor in a private house.

It is worth saying that insulating the floor in a private house is a simple process that absolutely anyone can handle. Indeed, such work cannot bring any difficulties. In this case, it is necessary to find a suitable thermal insulation material. In addition, you will need to select for this case modern technology floor insulation.

If you don’t know how to choose thermal insulation material for floor insulation in a private home, then before you go to the store, remember the following recommendations.

- So, floor insulation must have good thermal conductivity and excellent strength.

- Thermal insulation material should be light in weight so as not to create additional load on the load-bearing elements of the house.

- The insulation must withstand loads well and be fireproof.

- Thermal insulation material for the floor must be durable and moisture resistant.

In addition to all the characteristics described above, the thermal insulation material for the floor must be different environmental safety. Also, the insulation should be easy to install. Today, every owner of a private house will be able to choose unique technology And modern insulation. Below we will tell you in detail how to insulate the floor in a private house inexpensively.

We insulate the floor in the house using mineral wool

Mineral wool is an excellent insulation material that has high sound and heat insulation. This material is fire resistant. In addition, mineral wool can withstand even the most severe mechanical stress. Mineral wool is an excellent insulation material that retains its basic properties for a long time. Mineral wool is sold in stores in the form of flexible slabs and mats.

Flexible mats are distinguished by their high strength and elasticity. In this case, one side of one mineral wool mat is covered with perforated paper, which is located at the bottom of the structure.

Mineral wool is used for insulation in wooden structures floor, namely in the joists. Mineral wool is also used under black under the base of the surface.

Floor insulation with polystyrene foam

If you want to know how to insulate the floor in a private house above a cold basement, then we recommend that you use polystyrene foam for this purpose. It is worth saying that this insulation has not only a long service life, but also good thermal insulation properties.

This kind of material is widely used today. Basically, they are used to insulate the floor in a private house above the basement. Expanded polystyrene can be laid on absolutely any surface. It is quite convenient to use this material to insulate a concrete floor in a house. For this purpose, this insulation is first fixed to the floor, and then a reinforcing mesh is laid on it. And after that, a concrete screed is installed on the surface of the concrete floor.

We insulate the floor in our own house with penoplex

Penoplex is a well-known thermal insulation material that is used to insulate the most various designs. Why is this material so popular? It turns out that this material has the most best characteristics, which make such insulation a good alternative to polystyrene foam.

Penoplex insulation is suitable for insulating absolutely any structure. And if you plan to insulate the floor with this insulation, then it should be used when laying the base floor with subsequent screed.

We insulate the floor in your home using the method of applying polyurethane foam

Despite the fact that in every hardware store There is a huge selection of various thermal insulation materials; floor insulation in a private house with polyurethane foam is very popular. It must be said that such heat-insulating material is applied quickly and in an economical way by high-quality spraying method. After applying such thermal insulation on the floor surface, a smooth coating, which will not have joints or joints. The method of floor insulation with polyurethane foam has several advantages:

- This method is characterized by high speed of work completion.

- Insulation similar material implies minimal expenses.

- After insulation, a small but reliable thermal insulation layer of 50 or 100 mm is formed on the floor surface.

- Sprayed polyurethane foam does not require additional vapor barrier. In addition, this material has good moisture resistance.

- Similar thermal insulation material You can insulate the floor not only outside, but also inside the building.

- Polyurethane foam is not afraid of mold and rodents. Also, this material is resistant to serious temperature changes and other climatic phenomena.

- If you decide to insulate the floor with this particular material, then you can install absolutely any floor on top of this insulation.

We insulate the floor using double flooring

This option will not reduce the height, and will make living in the apartment more comfortable, due to the fact that the floor temperature can be adjusted. in a known way floor insulation is considered to be a method of floor insulation by means of double flooring. In this case, the first layer is created from smooth boards, which are usually attached to the beams with tongues. At this stage of work, it is imperative to prevent air from entering such a structure. As for the final layer, laminate is laid on a backing, linoleum or carpet.

We insulate the floor using fiberboard

Fiberboard sheets can become a decent thermal insulation material. This material can be freely used if it is impossible to raise the floor surface. For such a case, it is recommended to use Fiberboard brand M-20 and PT-100. You can easily lay any floor covering on fiberboard sheets, which will become the finishing layer of the floor.

We insulate the floor in a country house by using expanded clay

Floor insulation with expanded clay is affordable and the most known technology insulation. Insulation with expanded clay is carried out already during the installation of the screed. To insulate the floor, expanded clay is used in the form of bedding. And to increase the effect, this insulation is added to the concrete screed. And to increase the strength of the floor, a mesh is laid between the screed and expanded clay. And modern additives are added to the solution itself, which will further avoid cracking of the finished floor.

We install heated floors

To make a heated floor in your home, it is possible to resort to the option of installing a heated floor, which can be water or electric. Warm floors in the house, in addition to high-quality thermal insulation, provide the entire house high-quality heating. Electric heated floors are expensive. Therefore, such floors are mainly used for heating small rooms in the house. An electric floor does not affect the height of the room. It can easily be installed on the preparatory layer just before laying any finishing floor covering.

Floor insulation using gypsum fiber

More than ten years ago, one company managed to develop a unique product - gypsum fiber sheets, which have a number of advantages. It's worth saying that gypsum fiber sheet It has.