Roofs and flat roofs made of monolithic foam concrete. Comments. Pitched roof and how to create it yourself. Monolithic concrete roofing Flat roof in a private house without concrete

Common people often use two completely different words - roofing and roof - with the same meaning. In reality, this cannot be done. And any experienced builder will explain to everyone that a roof in this area means everything that is in the room, that is, above the living space, which is usually called the attic. But the roof refers to the very top part of the building, that is, the roof covering itself, which is irrigated by all kinds of precipitation, covering the inside of the house from piercing winds and hot sun rays.

The roof of the house protects from external natural factors, such as rain, wind, snow, so it is worth thinking about a durable and high-quality roof for your house.

However, you need to remember that before you think about creating a roof, you need to first arrange the roof. That is why, first of all, you need to learn the rules of how to do it yourself in a residential building or non-residential, but no less in need of covering, premises. Although it sounds proud - he made the roof with his own hands, any person capable of abstract thinking will understand that it will not only be difficult but, most likely, impossible to cope with such a difficult task alone.

Main types of roofs

Varieties of roof shapes. The most common are single-pitch and gable roofs.

Experts name only 2 types of roofs, which are considered the main ones in construction. These are flat and sloped. Both from the point of view of the materials used in this matter, and from the point of view of construction technology, they are fundamentally different from each other.

In order to make a roof of any type, you will need the following tools and materials:

- nails;

- bars;

- lathing board;

- roofing felt;

- hacksaw;

- hammer;

- chockline;

- roofing material.

How is a flat roof made?

Flat roofs, which we see mainly in industrial plants, factories, and, of course, on residential buildings, can be built with your own hands.

The main material from which a flat roof can be made is considered to be concrete slabs, and, whatever one may say, it will not be possible to build such a roof on a high-rise building with your own hands.

Flat roof structure.

Unless, of course, you are Hercules or Titan, who is capable of holding the firmament and can compete in strength with heavy construction equipment. But if you need to make a roof for some kind of adjoining building such as a cellar or garage, then almost any man will be able to independently erect a flat roof. Provided that the roof will be assembled from small elements or will be a monolith of reinforced concrete.

A stacked flat roof is made as follows: we lay beams, which can be made of metal or wood, on the walls of the building to be covered. They will serve as load-bearing structures, which will subsequently bear the main load of the roof. At this stage, you need to pay significant attention to how thick the installed beams will be. After all, they have to support not only the weight of the roofing material, but also the weight of snow, which is absolutely inevitable in the conditions of the Russian winter. Plus, the weight of at least one person who will have to clean this snow. Since it will not melt on its own for a long time, a flat roof does not allow snow to roll away on its own.

Flat roof for unheated rooms

An unheated structure, for example, a barn, garage, gazebo, terrace or canopy, requires a flat roof slope over the entire area of the room. To do this, the load-bearing beams are immediately installed with a slope. Then a wooden board is laid over them, which is obtained by continuously laying boards, on top of which roofing material is laid, which must be laid tightly to each other, thus constructing a kind of carpet. The higher the density of the roof lining with roofing felt, the lower the likelihood of leakage.

It is recommended to fasten roofing felt using slats, which in any case can be replaced with metal strips. They are nailed at a distance of 60-70 cm from each other along the slope, and this will not interfere with the flow of water. Leave the slope at least 3%. This means that for every m of roof length there is at least 3 cm of elevation.

Flat roof for living quarters

Attaching roofing material to a flat roof.

You can also make a flat roof with your own hands for heated buildings. In this case, you need to proceed as follows: the laid load-bearing beams are covered with a flooring of wooden boards and 1 layer of roofing felt or roofing felt is laid on top of it. The overlap of the strips must be at least 15 cm; insulation is poured on top of this layer, usually slag or expanded clay. With the help of insulation, a slope is formed in the direction where rainwater will flow and snow will be dumped. We apply a cement mortar screed over the insulation, the thickness of which should be at least 2 cm. We wait until the screed is completely dry and treat it with a bitumen primer, onto which a rolled roofing felt carpet is glued.

Monolithic flat roof made of concrete

When constructing a roof from monolithic concrete I-beams are used as support beams.

To successfully install a flat roof made of monolithic concrete, it is necessary to use metal structures as load-bearing structures. I-beams. When considering the construction of a roof whose span is 4-5 m, experts recommend using beams whose height is approximately 12-15 cm. In the language of professionals, this sounds like a “fifteenth I-beam”. It is better to buy concrete used to create a monolithic floor ready-made, because Mixing concrete with your own hands without using a concrete mixer will not allow you to achieve a uniform connection of all the components. The concrete will turn out to be heterogeneous, which will negatively affect the quality of the coating. To prepare concrete with your own hands you need:

- 3 buckets of cement;

- 4 buckets of sand;

- 8 buckets of crushed stone.

All this is mixed using 2 buckets of water. Sometimes a little more water is needed, so you can adjust the amount yourself.

Next, boards are laid on the lower flanges of the beams, on top of which 1 layer of roofing material or roofing felt should be laid dry. Then the reinforcement is placed so that with its help it forms a kind of mesh with cells, the approximate size of which should be 2x2 cm. In order to prevent the mesh from moving during concrete laying, the rods at the intersections must either be electrically welded together or tied together wire whose diameter does not exceed 2 mm. It is also necessary to provide small space between the mesh and roofing felt is not less than 4 mm, so that the reinforcement is completely covered with concrete. To achieve this goal, small pieces of crushed stone must be placed under the mesh. The prepared concrete is laid between the beams in a minimum layer of 15 cm.

When laying the monolith on the roof of a building, keep in mind that the stripes between the beams must be filled one at a time. Since this work will most likely take more than one day, and in order to achieve the highest quality screed, you should under no circumstances divide the concreting of one strip into several approaches. During this work, you need to carefully compact the concrete using a vibrator, and if you don’t have one, you can use a manual tamper. In this case, you need to try very hard not to displace or damage the reinforcing mesh laid in the base of the concrete screed.

After the concrete is laid, builders recommend closing it plastic film, in order to avoid too rapid evaporation of moisture from the concrete. It is especially important to do this in hot summer weather. If this is not done, the top layer of the roof will soon crack. The concrete mixture must be kept under the film for at least 3 days, after which the film can be removed.

After the concrete has completely dried, you can begin installing a slope, which is constructed using insulation, installing a cement screed, and, finally, gluing the rolled carpet. These steps are described above.

From the detailed description of how to make a flat roof with your own hands, it is clear that there are no particular technological difficulties here. The situation is much more complicated with a pitched roof, the construction of which requires high precision measurements in the manufacture of load-bearing structures, and then the roof itself. You can hardly cover it yourself, because a pitched roof has a greater angle of inclination than a flat one.

Pitched roof and how to create it yourself

They prefer to build pitched roofs on low-rise buildings - private one-, two- and three-story houses, as well as dachas, small cottages and, of course, five-story Khrushchev buildings. Often pitched roofs complete unique structures.

A pitched roof, which crowns a not very massive structure, for example, a garden house, a bathhouse or a gazebo, can be made with your own hands even if only 1 person will perform this work. And if you decide to build a pitched roof on a fairly large building, then it’s unlikely that you can do it alone; you’ll have to call two or three assistants.

How to make a pitched roof?

The basis of a pitched roof is taken from rafters, with the help of which quite complex structures are formed. In professional construction, this type of structure is called the well-known word “trusses”. As a rule, the rafters rest directly on the walls, but experts recommend installing a Mauerlat. In other words, a beam that is laid on the wall and secured to it with anchors. And the rafters rest against these bars, to which they are attached with metal brackets or other methods that ensure a reliable connection of the load-bearing structures.

The stages of creating a pitched roof involve the following sequence of actions:

- install the Mauerlat;

- we strengthen the rafters;

- we construct and install ridge beams;

- we make the sheathing.

Rafter system pitched roof for two spans of 6 meters.

We lay the roof directly along the created sheathing. When building a roof of this type, they try to extend the rafters beyond the edges of the walls, so that the roof overhang created in this way protects the wall of the building from moisture getting on it, for example, during rain or when snow melts. The best option is the lengthening of the rafters themselves, onto which you need to nail a board 2-3 cm thick. In the future, this board can be used as a base to which the overhang of the wind board will be sewn.

Rafters, as a rule, are assembled directly on the roof, having previously lifted the prepared elements onto them and assembled them according to the approved scheme directly on the roof. There is also the option of completely assembling a finished rafter truss, which consists of 2 rafter legs, racks and, of course, tie rods, right on the ground. After this, the assembled structure, which is quite bulky in size, is lifted vertically exactly to the place where it should stand. You cannot do this procedure yourself, no matter how hard you try, so you will have to use heavy equipment. After installing the truss on top of the house under construction, we attach it to the Mauerlat.

After completing the installation of the existing rafter structures, you can begin to connect them using a ridge beam, and then start lathing.

Creating a roof sheathing for the roof

The construction of the frame of any roof is carried out in two stages: installation truss structure and performing roof sheathing.

The easiest way to make a sheathing is from boards that are nailed “in a run,” that is, after some distance between them, or “solidly,” when the boards are nailed end to end. To ensure that this stage does not turn out to be too costly, you can use edged lumber with a thickness of only 25 mm. Before strengthening the boards on the roof, they must be thoroughly cleaned of any remaining bark. To nail the sheathing to the rafters, use 70 mm nails. The boards, as a rule, are not perfectly level, so if a continuous sheathing is installed, they will need to be adjusted on site using an ax to reduce the gaps between them.

The design of those elements that are used for sheathing and their sizes depend on what roofing materials you plan to use in your work. If your roof will be covered with metal tiles, then unedged boards are not advisable to use. It is better to replace it with timber, which must be nailed “in a running start”, at a distance equal to the wave of the roofing material used.

For those who use ondulin or various kinds of bitumen shingles, the sheathing is done as follows: purlins made of timber, the size of which is 40x50 mm, are nailed to the rafters at a distance of about 50 cm. OSB sheets are reinforced onto the resulting purlins using self-tapping screws. This solution will be successful for those who plan, for example, to create a living room instead of an attic. Similar solution called a mansard roof, thanks to which it is possible to successfully increase the living space of the house.

By itself, a well-insulated roof truss made of wooden blocks cannot create the cozy atmosphere that arises under a monolithic roof. This is explained by the fact that roof elements made of porous concrete or brick not only have thermal insulation properties, they also accumulate heat. Thus, a monolithic roof - good alternative traditional wooden beams.

Preparing for the construction of a monolithic roof

The most expensive part of the construction work for the construction of a monolithic roof occurs in the stage preceding the laying of the slabs. While in support construction farm in the most unfavorable case, linings can be made from wooden beams, and the walls of the pediment will acquire their own final form later, in the case of a monolithic roof, there is hardly any possibility of such a correction. Therefore, when constructing the supports of a monolithic roof, you need to do the work very pedantically. Already in determining the right angles of the horizontal projection, a lot of effort must be expended, but if the building is characterized by chamfered corners and balconies, then it is necessary to repeatedly check the angles of inclination of the roof and the position of the ridge crest with mathematical precision. It is best to pull the cords in the plane of the support of the slabs. Each block is first fitted dry, and the line of curvature of the supports is marked. Cutting blocks is very easy, especially if you build from porous concrete and have a band saw at your disposal.

Construction of a reinforced concrete ring anchor

If a reinforced concrete ring anchor is needed to support the slabs, the work can be difficult, since the connecting reinforcement is removed from the support, which then must fit accurately into the gaps between the slabs. In this case, the participation of a construction expert is recommended. The formwork for the ring anchor is made from thin blocks on the side. Then the reinforcement of the ring anchor is coupled with the connecting reinforcement and poured with concrete. Pre-wet the masonry walls. We recommend that a statics expert calculate whether to build the support with masonry or make it concrete. With a monolithic roof, supports and formwork are unnecessary. Once the monolithic roof slab supports are installed, lay the precast blocks with two helpers and a construction consultant from the monolithic roof supplier.

Monolithic roof installation

Within a few hours the roof is covered. Roof slabs consist of reinforced porous concrete or reinforced brick elements, which have full load-bearing capacity already upon delivery, therefore, with a monolithic roof, supports and formwork are unnecessary. Typically, aerated concrete monolithic roof slabs rest on the gable walls and load-bearing interior walls, so any roof slope and almost any span can be accommodated. However, for production reasons, prefabricated units may have maximum length only 6 m. If large spans must be covered, then reinforced concrete beams and steel I-beam supports, which you are already familiar with from porous concrete floors. While reinforced concrete beams under the roof, like large lintels, cross the room and are visible, steel supports can be built into the plane of the slab and later completely invisible. In this way, monolithic roof structures are manufactured for almost every plan.

Installation of a roof window

Dormer windows can also be built into the plane of a monolithic roof. In any case, this is only done with a custom made steel frame. In most cases, such a building part made of steel rests on the side walls and serves as a reliable support for those roof slabs that were disconnected for the construction of the roof window. The larger the window needs to be, the more expensive the frame will cost. Dormer windows can be made from a steel frame near load-bearing internal walls running parallel to the gable, if the separated roof slabs respectively have at least two supports: on the gable and on interior wall. The roof slabs are then laid as cantilever slabs, similar to balcony slabs, and do not require a steel frame. Of course, it is also possible to provide a maintenance hatch in the monolithic roof.

Remember that retrofitting roof windows into the plane of a monolithic roof is completely excluded! A monolithic roof, just like a floor slab, is a building block whose load-bearing capacity is guaranteed in a unified system for calculating static load parameters.

In the second part of the article “Construction of a monolithic roof,” read about concreting a ring anchor, thermal insulation of the roof, installation of sheathing, guttering and roofing of a monolithic roof.

The invention relates to the field of construction, namely to the arrangement of roofs. The technical result of the invention is to increase operational reliability roofs. In a monolithic roof - a protective coating for operational purposes, made multilayer and consisting of a slope-forming screed 2 laid on the base 1 of the load-bearing floor slab, a primer layer 3, when applied covered with quartz sand 4, which performs the function of a vapor barrier layer, the waterproofing layer 5 is made in the form of a waterproofing membrane pouring from polymer materials of increased elasticity, for example methyl methacrylate, types of matacrylic, polyurethane and other polymers that can withstand stretching (elongation) at break of at least 200%. The load-bearing high-strength layer 6 is made of a polymer binder of similar origin, but with lower deformation characteristics and is filled with quartz sand at least 100% by weight of the binder. In the finishing top layer 7, made of polymer, the thickness, color, chemical resistance, degree of roughness and other characteristics are determined by the operating conditions of a particular roof, while all polymer layers are made in a seamless monolithic design. 5 salary f-ly, 4 ill.

Drawings for RF patent 2441121

The invention relates to the field of construction, namely to the arrangement of roofs or protective coverings of various structures for operational purposes, such as parking lots, sports facilities, residential buildings, leisure centers, shopping and exhibition halls, etc.

The modern choice of thermal insulation, waterproofing and finishing materials makes it possible to operate the roof practically without any serious technical barriers and to include these materials in projects when designing new cottages and estates. Such usable roof solutions save space and are also an attractive architectural design element.

The installation of a serviceable roof is a complex engineering task that requires compliance with a number of requirements for modern high-tech roofing coverings.

A known roof for a building with flat roof, made multilayer, consisting of a waterproofing layer located on the surface of the base of the roof, a heat-insulating layer of densely packed rubber crumbs, a layer of polymer material, a porous layer, which is a hardened binder of polymer material with a filler in the form of rubber crumbs placed in it, all layers, except for the heat-sound-insulating and waterproofing layers, are laid using the method bulk technology with the possibility of ensuring their interconnection through a polymer material and the formation of a monolithic structure of the roof covering (RF patent No. 58577, published on November 27, 2006).

The disadvantages of the analogue are associated with the high degree of deformability of the structure, which uses elastic polymer materials filled crumb rubber. For any heat and sound insulating layer, a necessary condition for ensuring thermophysical characteristics is the invariance of its geometric shapes, since any changes (deformations) change the density of the heat-insulating layer and its porosity, and, consequently, the thermal conductivity characteristics towards deterioration. In addition, the roofing technology used in the analogue creates heterogeneity of the structure in the heat-insulating layer, since after pouring polymer material over this layer, in its upper part the entire porous space is filled with polymer material, and thus it becomes divided into two parts: the lower - porous and top with filled pores of the self-leveling layer material. In this case, the porous (upper finishing) layer is also filled with rubber crumbs and polymer material, only initially mixed with it in the bulk layer. Such a structure, heterogeneous in properties, but connected into a monolith during the period of sharp daily temperature fluctuations in winter period, for example, in St. Petersburg, where normal daily differences are from -10 to +10°C, increases the likelihood of a dew point appearing inside the structure, with all the ensuing negative consequences.

The low resistance of elastic polymer structures to piercing and cutting loads requires the creation of a protective layer, for example, from gravel or crushed stone, which is unacceptable for a heat insulating layer. In addition, any other loads on the roof (pedestrian traffic, mechanical loads, including transport, snow), due to its deformability, can change the geometric parameters, including the specified slopes, which will lead to the formation of water accumulation places randomly located on the roof ( puddles), which turn into ice in winter. For these reasons, the operation of such a roof is impossible.

A traditional flat exploitable roof is known, consisting of a vapor barrier layer, rigid insulation, a slope-forming layer and screed, a waterproofing layer consisting, for example, of a welded roll material or a polymer roll membrane, connected to each other by welded seams, a protective layer, including a geotextile a layer to protect against spillage of gravel with sharp edges, for example, granite gravel is used as drainage, and a top layer consisting, for example, of paving slabs (SNiP II-26-76. Roofs. Appendix II, type P-9, with .14).

The disadvantages of the prototype are that although such a roof protects the waterproofing layer from the fall of heavy and sharp objects, it improves due to the protective layer of granite gravel and paving slabs fire properties, however this type roofing is not intended for use as an operational roof with corresponding loads and functional purposes, for example, parking lots, traffic and parking of vehicles and cleaning equipment, recreational areas and terraces, ramps and overpasses, galleries, cafes, sports grounds.

An inversion roof is known, consisting of a concrete floor slab with a slope arranged on it, on top of which there is a reinforced screed made of a cement-sand mixture, primed with bitumen primer TECHNONICOL No. 1, a roofing carpet made of two layers of waterproofing material, the bottom one made of Technoelastmost B or Technoelast- Fix, the top of Technoelastmost B or Technoelast-Green, which is covered with a layer of needle-punched geotextile TechnoNikol, a layer of thermal insulation located on top of the waterproofing layers and performing the function of protecting the building from moisture entering it, a drainage layer for removing moisture arranged on the upper surface of the thermal insulation slabs, with laid on it is insulated, on which a drainage layer of granite gravel is applied, on top of which a reinforced screed is laid, before laying which the previous surface is covered with glassine or roofing felt, forming a separating layer on which the top layer is applied - asphalt concrete (Guide to the design and installation of exploited roofs using bitumen -polymer materials of the TechnoNIKOL company, M., 2005, section 3, subsection 3.1. Inverted operable structure used for moving or parking vehicles).

Based on the largest number of similar features and the result achieved when used, this technical solution was chosen as a prototype of the claimed invention.

The disadvantages of the prototype are that the structure is overloaded due to the slope-forming (under the waterproofing layer) and protective (above the heat-insulating layer or in its absence above the waterproofing layer) screeds, as well as the upper operating layer leads to high loads on the load-bearing slab, to remove which it is necessary to carry out additional expensive measures to increase the load-bearing capacity of the base. If the continuity of the waterproofing layer is broken (leaks occur) and if repair work is necessary, for example, dismantling the top layer of an inversion roof, the reuse of which, like the screed above the heat-insulating layer, is impossible, as a result of which a new screed is required, which is an expensive operation. Due to the multi-layer structure of the roof, which involves draining water from several intermediate layers, even with slight deformations of one of them, the risk of leaks increases due to movements in transition zones (joints) and along multi-level drainage funnels, which requires frequent repairs with partial dismantling the roof in drainage areas.

The technical result to be achieved by the claimed invention is to increase the efficiency and expand the types of operation of the roof, optimize and reduce the cost of its design and increase reliability during operation.

To achieve the specified technical result in a monolithic roof - a protective coating for operational purposes, made multilayer and consisting of a slope-forming screed laid on the base of the load-bearing floor slab, a primer layer, when applied filled with quartz sand, performing the function of a vapor barrier layer, the waterproofing layer is made in the form of a poured waterproofing membrane made of polymer materials of increased elasticity, for example methyl methacrylate, types of matacrylic, polyurethane and other polymers that can withstand tension (elongation) at break of at least 200%, the supporting high-strength layer is made of a polymer binder of similar origin, but with lower deformation characteristics and is filled with quartz sand of at least than 100% by weight of the binder, and in the finishing top layer, made of polymer, the thickness, color, chemical resistance, degree of roughness and other characteristics are determined by the operating conditions of a particular roof - a protective coating, while all polymer layers are made on a slope-forming concrete screed in a seamless monolithic design.

In addition, the declared decision has optional features that characterize its special cases, namely:

To protect the slope-forming concrete screed from cracking and ensure the strength of the base under the polymer layers, it is made of concrete with a strength of at least M250 (B20), a thickness in its lower part of at least 40-50 mm, and a thickness of at least 0.75t over the entire area, where t is the thickness of the slope-forming concrete screed, with cards with a pitch L of no more than 6×6 m, expansion temperature-shrinkage joints filled with polymer material of the monolithic roof are cut - protective coating;

The expansion joint of a slope-forming concrete screed is made of a waterproofing key installed at the bottom of the joint, on top of which the entire space is filled with an elastic polymer material, so that the waterproofing membrane and the expansion layer work together without an intermediate primer layer laid only along concrete base slope-forming concrete screed and vertical surfaces of expansion joints and junctions of the screed to the walls (parapets);

At the junctions, the waterproofing membrane is placed on the walls (parapets), while the composition of the polymer material includes thixotropic additives, and the load-bearing highly filled layer of polymer material is made in the form of a plinth with a height h of at least 10-15 cm, the space between the slope-forming concrete screed and the parapet is filled elastic polymer material;

To relieve stress concentrations on the polymer layer, sharp corners slope-forming concrete screed in expansion joints and abutments are cut at an angle of 45°;

When using a monolithic roof - a protective coating in temperate climatic zones or with minor temperature changes that do not cause significant temperature deformations in the screed, a waterproofing membrane can be applied only in places of possible structural movements of the load-bearing elements of the building, abutments to the walls of parapets or expansion joints, and the load-bearing The high-strength roofing layer is applied directly to the primer layer.

The distinctive features of the proposed device from the one mentioned above, which is closest to it, are the implementation of a waterproofing layer in the form of a poured waterproofing membrane from polymer materials of increased elasticity that can withstand tension (elongation) at break of at least 200%, the implementation of a high-strength load-bearing layer from a polymer binder of similar origin, but with lower deformation characteristics, filled with quartz sand at least 100% by weight of the binder, making the finishing top layer polymer and making all polymer layers in a seamless monolithic design.

Due to the presence of these features in the proposed monolithic roofing - a protective coating for operational purposes, the solidity and seamlessness of the coating is preserved, since the use of a material of the same origin, but with different characteristics(brands) allows, with a small roof thickness, to meet the requirements for operating roofs. In this case, the multilayer structure works as a single monolithic structure with different characteristics and functional purposes of the layers, but high adhesive and mechanical interlayer strength, water resistance, for example, vapor barrier - primer layer, waterproofing - elastic layer, load-bearing - high-strength layer, top - protective and finishing top -layer. Making layers from polymer materials makes it possible to regulate (improve, if necessary, existing brands) various characteristics of layers by introducing special additives into the polymer composition, for example, thixotropic additives - for application to vertical surfaces, fire retardant additives - to increase fire resistance classes, etc.

Filling compensation temperature-shrinkage (and expansion joints and junctions with walls (parapets)) with an elastic polymer composition of a waterproofing membrane improves the performance characteristics of a slope-forming concrete screed by creating a protective damping layer that ensures the unloading of this screed from extreme temperature-shrinkage deformations, preventing its destruction, and increases reliability waterproofing membrane while ensuring the continuity of the waterproof layer, since the main volume of deformation loads is “damped” in the seams, creating a “reserve of strength” for the main waterproofing layer of the proposed roof.

All layers of a monolithic roofing - protective coating are completely waterproof, both individually and in a monolith. Accordingly, the collection and drainage of water into drainage funnels is carried out only from the surface of the proposed roof and does not require multi-tiering.

The multi-layer nature of such a roof makes it possible to redistribute loads between layers, creating a kind of “reserve” of strength, which, when one layer is destroyed, does not entail the immediate destruction of the next one. In the proposed invention, due to the created rigid adhesive bonds between the layers of the polymer coating, the possibility of water penetration under the polymer layer is excluded. Possible destruction, for example, disruption of the continuity of the waterproofing membrane, will be limited only to a local area, which is easily identified visually and does not require dismantling the entire roofing carpet.

The use of colored quartz sand in the load-bearing high-strength layer makes this roof decorative. And if necessary, you can create drawings by combining various colors sand. Drawings (areas of different colors) are made using separate cards according to templates and do not violate the continuity (water resistance) of the load-bearing high-strength layer. Another design solution could be to lay a film with photo drawings on the supporting layer and cover it with a transparent finishing layer. In addition, the finishing layer itself can be colored (pigmented).

The minimum thickness of the waterproofing membrane, and therefore the loads transferred to the base, create significant reserves for the installation of additional operational structures on it, for example, sports fields, fountains, mini-pools, flower beds, a helipad, without strengthening the existing load-bearing elements of the building structure.

The high degree of resistance to temperature deformations and the small thickness of the roof make it possible to install heating systems on a slope-forming concrete screed, without deteriorating the characteristics of the roof carpet, ensuring the absence of frozen and snow-covered areas during periods of negative temperatures.

The proposed monolithic roofing - protective coating for operational purposes is illustrated by the drawings presented in Figs. 1-5.

Figure 1 shows a section of a monolithic roof - a protective covering.

Figure 2 shows cutting of expansion expansion joints.

Figure 3 is a cross-section of the monolithic connection unit roofing-protective coating with expansion joint.

Figure 4 is a section of the junction of the monolithic roof-protective covering to the walls (parapets).

A monolithic roofing-protective coating for operational purposes consists of a roof base 1, for example, a load-bearing floor slab, a slope-forming concrete screed 2, a vapor barrier layer of a primer polymer 3, quartz sand 4, a waterproofing membrane made of an elastic polymer material 5, a load-bearing high-strength layer 6 of a polymer a binder of similar origin with lower deformation characteristics and filled with quartz sand 4, finishing top layer 7, expansion temperature-shrinkage joints 8 filled with polymer material 9, expansion joints of the screed 10 and base slab 11, abutment 14 of the upper part of the concrete screed 2 to the walls ( parapets) 12, plinths 13, waterproofing dowels 15.

Monolithic roofing - a protective coating for operational purposes works as follows (Fig. 3).

A slope-forming concrete screed 2 with a concrete strength of at least M250 (B20) and a thickness in its lower part at the drainage funnels of at least 40-50 mm is laid on the base of the proposed roof - a protective covering consisting of a load-bearing slab 1 of the floor. Expansion joints 10 of the slope-forming concrete screed 2 are combined with expansion joints of the load-bearing slab 1 of the floor. In places where expansion joints 10 are installed and where 14 of the slope-forming concrete screed 2 is connected to the wall (parapet) 12 (Fig. 4), removable formwork is installed. Next (Fig.2) after laying the concrete in the slope-forming concrete screed Using 2 cards with a step L of no more than 6×6 m, expansion temperature-shrinkage joints 8 are cut over the entire area to a depth of at least 0.75t and filled with polymer material 9. Sharp corners of the slope-forming concrete screed 2 in the upper part of the expansion joints 10 and abutments to the walls (parapets) 12 are cut at an angle of 45° (Fig. 3, 4). After preparing the base of the roof 1, removing the removable formwork, grinding and removing dust from the slope-forming concrete screed 2, a primer layer 3 is applied from a polymer material, for example methyl methacrylate, which has not only the characteristics required for the operation of a monolithic waterproofing roof, but also technological advantages compared to other polymer materials ( rapid, within 1-2 hours, strength gain); to increase the adhesion of the primer with the overlying layers, quartz sand is sprinkled evenly over its surface 4. Along with applying a vapor barrier layer of primer polymer 3, 9 expansion temperature-shrinkage joints 8 are also filled with polymer material. In the lower part of expansion joints 10 and junctions 14 in the slope-forming concrete In screed 2, waterproofing dowels 15 are installed.

On the thus prepared primer layer (polymer) 3, with a thickness of at least 1.5-3.0 mm, a waterproofing layer in the form of a waterproofing membrane made of elastic polymer material 5 with high deformation characteristics, for example acrylic compounds Nanten DC 225, is applied over the screed using the pouring method. or the modified urethane coating Nanten Matacryl, which has high adhesion to acrylics.

Before applying a layer of waterproofing membrane, expansion joints 10 and abutments 14 of the inner part of the slope-forming concrete screed 2 to the walls (parapets) 12 are filled with these compounds, and in places where the upper part of this screed 2 adjoins the walls (parapets) 12, the waterproofing membrane is smoothly filled with a slight increase in thickness by the corner part is placed on the walls (parapets) 12. This allows the expansion joints 10 to withstand various loads during operation (compression, bending and tensile deformations, etc.), i.e. perform the functions inherent in a load-bearing structural element, while simultaneously protecting the slope-forming concrete screed 2 and acting as a stress compensator from the occurrence of extreme stresses that can cause its destruction.

Similarly, expansion temperature-shrinkable joints 8, made to relieve stress in concrete and prevent it from operating under extreme (destructive) deformation loads, when filled with a polymer composition, actually glue the sections cut into cards, on the one hand, they create additional strength reserves for the action of extreme loads, and on the other hand, they are created on a slope-forming concrete screed 2 monolithic base, over which the load from external (vertical) loads associated with the operation of the proposed roof is evenly distributed. Thus, filling the deformation 10 and expansion temperature-shrinkage 8 joints in this roof with polymer materials provides for the creation of rigid adhesive bonds between the polymer and concrete in the seams, giving a new quality to the slope-forming concrete screed 2, which works as a monolithic slab (structure) of concrete and polymer, which makes it possible to evenly redistribute all emerging loads (stresses) on it, significantly increasing the operational reliability of this roof base.

Next, a load-bearing high-strength layer 6 is applied to the waterproofing membrane with a thickness of at least 2-6 mm, made of a polymer binder, for example Nanten DC 205 acrylic varnish, which has less tensile strength (elongation) but greater compressive strength, filled with quartz sand 4 with a mass of not less than 100% by weight of the binder. At the junction 14 of the slope-forming concrete screed 2 to the walls (parapets) 12, the load-bearing high-strength layer 6 is made in the form of a plinth 13 with a height h of 10-15 cm.

In climatic zones where temperature fluctuations during the day are large, for example in St. Petersburg, it is advisable to mix Nanten 225 and Nanten 205 in a ratio of 50:50, which will significantly increase the deformation characteristics of the load-bearing high-strength layer 6 without changing its compressive strength. And the size of the quartz sand fraction 4 is selected depending on the thickness of the load-bearing high-strength layer 6 and is no more than 1/3 of its thickness. The use of colored quartz sand expands the decorative possibilities of the proposed monolithic roofing - protective coating, without compromising its characteristics and is selected based on the selected architectural solutions on this roof - a protective coating.

On top of the supporting high-strength layer 6 by painting or pouring, depending on the thickness of the layer, a finishing top layer 7 of acrylic coating, for example Nanten 305 varnish, which must be highly durable and UV resistant. The thickness of the coating, color, and when filling the high-strength load-bearing layer with colored quartz sand, its colorlessness, degree of roughness and other decorative and geometric parameters of the finishing top layer 7 are selected based on the actual operating conditions of the proposed roofing-protective coating.

Rigid adhesive bonds between the layers completely prevent the penetration of water into the interlayer space. In the event of a violation of the continuity of the waterproofing membrane 5 in the proposed roofing - protective coating, the destruction can be local and easily detected, and repairs are carried out within several hours without dismantling most layers.

Therefore, the creation of a single monolithic, rigidly bonded, multilayer homogeneous polymer construction, on the one hand, allows you to redistribute the loads transferred to it, and on the other hand, due to the individual properties of each layer, together with other elements of the roof (deformation 10 and compensation temperature-shrinkage 8 seams, abutments 14) assume the maximum for this particular area loads: in the lower layer - tensile deformations, in the upper part - compressive stresses. In the event of failure or destruction of one layer, this does not entail the immediate destruction of others, since stress relief occurs only in the destroyed layer, and the rest remain completely waterproof. Those. The multi-layer roofing actually creates several levels of protection for the structure and localizes possible violations of the continuity of the waterproofing. And the presence of a waterproofing key 15 prevents the flow of water from the roof into the underlying premises of the building in the event of destruction of the entire multilayer structure.

The absence of technological operations associated with the use of fire (for example, the mandatory use of a burner for fusing rolled materials on traditional roofs) significantly increases the fire safety of the proposed roof - a protective coating both during its construction and during repairs.

Thus, the proposed roofing - protective coating for operational purposes makes it possible to increase the reliability of the roofing - covering during its operation and its efficiency due to the multi-layer coating, giving a new quality to the slope-forming concrete screed, as the main load-bearing element of the roof, located in a rigid adhesive bond with polymer coating, eliminate water resistance, localize violations of the continuity of waterproofing as a whole, create additional reserves for the strength of the load-bearing base of the roof.

FORMULA OF THE INVENTION

1. Monolithic roofing is a protective coating for operational purposes, made multilayer and consisting of a slope-forming screed laid on the base of the load-bearing floor slab, a primer layer, when applied covered with quartz sand, performing the function of a vapor barrier layer, characterized in that the waterproofing layer is made in the form of a waterproofing membrane poured from polymer materials of increased elasticity, for example methyl methacrylate, types of matacrylic, polyurethane and other polymers that can withstand tension (elongation) at break of at least 200%, the supporting high-strength layer is made of a polymer binder of similar origin, but with lower deformation characteristics and is filled with quartz sand not less than 100% by weight of the binder, and in the finishing top layer, made of polymer, the thickness, color, chemical resistance, degree of roughness and other characteristics are determined by the operating conditions of a particular roof - a protective coating, while all polymer layers are made on a slope-forming concrete screed in a seamless monolithic design.

2. Monolithic roofing - a protective coating according to claim 1, characterized in that to protect the slope-forming concrete screed from cracking and ensure the strength of the base under the polymer layers, it is made of concrete with a strength of at least M250 (B20), with a thickness in the lower part of at least 40 -50 mm, and over the entire area with a thickness of at least 0.75t, where t is the thickness of the slope-forming concrete screed, while compensation temperature-shrinkage joints filled with polymer material of the monolithic roof - protective coating are cut with cards with a step L of no more than 6 × 6 m .

3. Monolithic roofing - a protective coating according to claim 1, characterized in that the expansion joint of the slope-forming concrete screed is made of a waterproofing key installed in the lower part of the seam, on top of which the entire space is filled with an elastic polymer material, so that the waterproofing membrane and the expansion layer worked together without an intermediate primer layer, laid only on the concrete base of the slope-forming concrete screed and the vertical surfaces of expansion joints and junctions of the screed to the walls (parapets).

4. Monolithic roofing - a protective coating according to claim 1, characterized in that at the junctions the waterproofing membrane is placed on the walls (parapets), while the composition of the polymer material includes thixotropic additives, and the load-bearing high-strength layer of polymer material is made in the form of a plinth with a height h not less than 10-15 cm, the space between the slope-forming concrete screed and the parapet is filled with elastic polymer material.

5. Monolithic roofing - a protective coating according to claim 1, characterized in that to relieve stress concentrations on the polymer layer, the sharp corners of the slope-forming concrete screed in expansion joints and junctions are cut at an angle of 45°.

6. Monolithic roofing - protective coating according to claim 1, characterized in that when using a monolithic roofing - protective coating in temperate climatic zones or with minor temperature changes that do not cause significant temperature deformations in the screed, the waterproofing membrane can be applied only in places where possible structural movements of the load-bearing elements of the building, abutments to the walls of parapets or expansion joints, and the load-bearing high-strength layer of the monolithic roof - the protective coating is applied directly to the primer layer.

Before we understand whether it is possible to equip a roof with our own hands, we will try to understand what a roof is and how it differs from a roof, because people often confuse these two concepts. Secondly, even a professional cannot cope with the installation of a roof, much less a roof, alone, so find one or two assistants. Otherwise, the result will not please you.

DIY roof: differences between a roof and a roof

Often people who have nothing to do with construction confuse roofing and roofing, even though these are two radically different categories. The roof is exactly what is above the living space, and the roofing is installed on top of the roof, that is, the roof is the material that covers the house, for example, tiles, roofing felt, and much more. The roof can be flat or pitched, but it is worth noting that you can forget about a pitched version made by yourself, since this is a complex process that requires serious professional miscalculations. To work with concrete, you will need special equipment; by the way, today renting a concrete mixer is a very reasonable solution, because purchasing it for private construction is not justified.

Therefore, only specialists will be able to do this process. Moreover, even a master cannot cope with this process alone, only with the help of additional team members; at least three people must be present to achieve a high-quality result. A flat roof most often involves the installation of a monolithic slab, which requires heavy equipment, which is also not conducive to doing it yourself. But a self-leveling flat roof made of monolithic concrete will become available.

Do-it-yourself flat roof made of monolithic concrete

Installing a monolithic concrete roof requires only physical strength and at least a slight understanding of the construction process. To begin, install I-beams, preferably 12 or 15 millimeters. Then lay the boards tightly and lay the roofing felt on a dry surface, then lay the reinforcement lengthwise and crosswise, you should get a mesh with cells 20*20 centimeters, weld the intersections using electric welding. Now pour the concrete. To create it, it is better to use a concrete mixer; manually it will not reach the required consistency. Smooth it out and leave it to dry. That's it.

__________________________________________________The construction of a gable or hip roof is not always rational and advisable when it comes to outbuildings, industrial and commercial facilities, and sometimes private homes in a modern style. The high consumption of material and the complex rafter system make the construction of these structures an economically unprofitable and protracted undertaking. While flat roofing projects significantly reduce construction costs, are quick to build and suitable for almost any structure.

A house with a flat roof is reliably protected from increased wind loads. However, without slopes, it cannot quickly drain rain and melt water from the roof surface.

The situation is complicated by the fact that the surface of roofing materials has a rough structure, which does not allow moisture and snow to slide off freely. Therefore, the installation of a do-it-yourself flat roof must meet the strict requirements of building codes for waterproofing, slope and construction technology.

The structure of the roofing pie

The need for a high level of protection from moisture forces the roofing materials of a flat roof to be placed in layers, one above the other, forming a so-called “pie”. If you look at its cross-sectional structure, you can see the following layers:

- Flat base made of concrete slabs or profiled metal sheets. It provides rigidity to the structure, bears the weight of the roofing pie, transferring it to the load-bearing partitions and, ultimately, to the foundation. The base of the roof in use must be as rigid as possible.

- Vapor barrier. A layer that is necessary to protect a flat roof from the penetration of vapors from internal heated rooms into the thickness of the insulation. When water settles on the thermal insulation in the form of condensation, it irreversibly reduces its insulation properties by more than half. The simplest vapor barrier is polyethylene film or bitumen-based coatings.

- Insulation. For thermal insulation of a flat roof, backfill materials are used, such as expanded clay, perlite, slag, rolled materials, for example, mineral wool, and in the form of slabs, in particular polystyrene foam. By the way, insulation is used not only to regulate the temperature, but also to tilt a house with a flat roof. The main requirements for insulation are low hygroscopicity and thermal conductivity, light weight.

- Waterproofing. A flat roof allows the use of roll materials for covering to protect against moisture: bitumen, polymer and bitumen-polymer. In addition to high waterproofing qualities, they must have resistance to temperature changes, elasticity, and a long service life.

Types of roofing and nuances of their installation

The construction of a flat roof is determined by the design and nature of its use. Some types that require a special approach during construction include the following:

Roof installation for unheated buildings

If a flat roof is being built with your own hands for an unheated utility room, for example, a barn, gazebo, shed or outbuilding, the slope is organized using support beams.

They are installed at an angle of 3 degrees, which is 30 mm for each linear meter of beam length. Then a base of unedged boards is laid on the beams, secured with nails or self-tapping screws.

Roofing felt, the most affordable material, is used as a waterproofing agent. It is produced and sold in roll form. The waterproofing is cut by cutting strips so as to lay them in the direction of the slope of the flat roof.

Strips of roofing felt are laid step by step with an overlap of 10-15 cm and fixed wooden slats or steel strips every 60-70 cm in the direction of the drain, so as not to block the path of flowing moisture. A flat roof of an unheated room can be easily installed with your own hands, even by one worker without the help of helpers.

Roof installation for heated structures

If they build private house with a flat roof, which they plan to connect to the heating system, then the work takes place in the following order:

To build a house with a flat roof, the length of which exceeds 6 m, a beam with a cross-section of 150x150 mm or more, or a steel I-beam, is used to make support beams.

Monolithic concrete roofing

Another option for building a flat roof with your own hands is to use monolithic concrete. The process looks like this:

Leaning process

– arrangement of a small angle of the roof surface to organize drainage. Before building a house with a flat roof, it is better to decide in advance which drain you will install, internal or external, and make a drawing.

If provided, water should flow into water collection funnels using a slope, which are located 1 per 25 sq.m or more often. If you make an external drain, then moisture should enter the gutter. The slope is formed using the following methods:

A flat roof without proper slope is an unreliable shield between you and bad weather. Moisture that has no outlet will accumulate on the roof surface, causing roof destruction and leaks.

Before we understand whether it is possible to equip a roof with our own hands, we will try to understand what a roof is and how it differs from a roof, because people often confuse these two concepts. Secondly, even a professional cannot cope with the installation of a roof, much less a roof, alone, so find one or two assistants. Otherwise, the result will not please you.

DIY roof: differences between a roof and a roof

Often people who have nothing to do with construction confuse roofing and roofing, even though these are two radically different categories. The roof is exactly what is above the living space, and the roofing is installed on top of the roof, that is, the roof is the material that covers the house, for example, tiles, roofing felt, and much more. The roof can be flat or pitched, but it is worth noting that you can forget about a pitched version made by yourself, since this is a complex process that requires serious professional miscalculations. To work with concrete, you will need special equipment; by the way, today renting a concrete mixer is a very reasonable solution, because purchasing it for private construction is not justified.

Therefore, only specialists will be able to do this process. Moreover, even a master cannot cope with this process alone, only with the help of additional team members; at least three people must be present to achieve a high-quality result. A flat roof most often involves the installation of a monolithic slab, which requires heavy equipment, which is also not conducive to doing it yourself. But a self-leveling flat roof made of monolithic concrete will become available.

Do-it-yourself flat roof made of monolithic concrete

Installing a monolithic concrete roof requires only physical strength and at least a slight understanding of the construction process. To begin, install I-beams, preferably 12 or 15 millimeters. Then lay the boards tightly and lay the roofing felt on a dry surface, then lay the reinforcement lengthwise and crosswise, you should get a mesh with cells 20*20 centimeters, weld the intersections using electric welding. Now pour the concrete. To create it, it is better to use a concrete mixer; manually it will not reach the required consistency. Smooth it out and leave it to dry. That's it.

__________________________________________________For many people, the name “flat roof” is associated primarily with multi-story buildings. A flat roof - the pros and cons of which we will consider in this article - was practically not used in low-rise construction a dozen years ago. However, today the creation of such a roof in country house is not a problem: modern materials and technologies make it possible to create a flat roof with appropriate consumer characteristics and at an affordable price.

- A flat roof is significantly smaller in area than a pitched roof, which allows you to save on materials and construction installation work Oh.

- Thanks to the relatively smaller area of the flat roof, it is possible to optimize costs.

- The construction of a flat roof is carried out easier and in a shorter time, in comparison with a pitched roof, since necessary materials for installation, they are located directly at the workers’ feet on a flat surface. The same can be said about the repair and maintenance of a flat roof - working on an almost horizontal roof is incomparably more comfortable than on a sloping one.

- On a flat roof, installation and subsequent service work with all kinds of equipment (air conditioning systems, solar panels, antennas, etc.).

- The use of a flat roof is an opportunity to obtain additional useful territory, which can be used as a place where you can relax on fresh air, play sports, create a garden, flower garden, etc. Today, there are technologies that make it possible to cover the roof even with paving slabs or paving stones. Roof, paved beautiful tiles, in combination with a green lawn, garden furniture, a gazebo and a fireplace, can become a place for a comfortable family holiday.

Houses with flat roofs are very popular now

A flat roof, in addition to its advantages, has a number of disadvantages:

- As a result of heavy snowfalls, a lot of snow accumulates on flat roofs, which, when melted, often causes leaks.

- Sometimes the use of internal drains is required.

- There is a risk of the internal drain becoming clogged or freezing.

- There is a need for mechanical cleaning of the roof from too large accumulations of snow.

- Regular monitoring of the moisture content of the insulation and the tightness of the roof is necessary.

Types of flat roofs

There are four types of flat roofs:

Flat roof base

According to building codes a flat roof, the pros and cons of which we discussed above, must have a base in the form of reinforced concrete floor slabs or corrugated sheets.

Subtleties of waterproofing

The durability of the roofing structure and its resistance to various negative influences depends on the use of special mixtures and technological processes production of roofing materials. Depending on the roofing materials, they are usually divided into three categories:

- Bitumen roofs, as well as polymer-bitumen based on roofing felt. These materials are available due to their low cost. Fused bitumen-polymer compositions are roll waterproofing and roofing sheets based on synthetics, on both sides of which a special bitumen is used that retains elasticity even at extremely low temperatures (down to -50 degrees Celsius). During the installation of waterproofing, carried out using gas burners, the rolls are fused together. Roof waterproofing can also be carried out with self-adhesive materials based on polymers and bitumen. In this case, the mastic is applied to the bottom surface of the roll and, when treated with a solvent, acquires the properties of glue. The disadvantage of bitumen roofing is its fragility.

- Membrane roofs with a base made of foil, rubber or polymers. This material has solid strength and is resistant to fire and other negative environmental influences. The membranes are glued to the screed or simply lie on the base, being loaded with ballast, or are attached mechanically or using glue. To connect membrane sheets, special welding machines, holding the material together with hot air.

- Roofs based on liquid polymers, which after cooling do not form seams. Such materials are especially often used for structures with complex geometries.

It is very important to do proper waterproofing flat roof

Whatever material is chosen, the joints between the rolls and the junctions with various roof elements must be waterproof. One of the main components of a successful waterproofing device is a high-quality sealant. During the period of operation, the roof is subject to negative influences of the external environment (moisture, hail, stones, strong temperature changes, etc.). Therefore, a high-quality sealant must be resistant to mechanical and temperature influences.

Mastic is usually used as a sealant - putty, which is based on elastic polyurethane resins. After application to the roof, the mastic polymerizes, resulting in the formation of a continuous rubber-like membrane that has waterproofing properties and protects roof covering from mechanical damage.

Mastic is ideal for flat roofing, it is safe, has high adhesion to building surfaces, and is highly resistant to ultraviolet radiation, precipitation and all kinds of microorganisms. It is applied with a brush, roller or airless spray - in two multi-colored layers, which allows you to control the quality, layer thickness and uniformity of distribution of the sealant.

How to arrange water drainage

Regardless of the materials used, a flat roof must have a certain slope to drain water (usually within 3-5%) that appears on the roof as a result of precipitation. The drainage system should be thought out at the building design stage. Gutters determine how effectively moisture will be removed from the roof surface. To prevent gutters from freezing in winter, they are equipped with special thermal cables.

Drains can be organized, when both external and internal water supply is created, and unorganized. When creating an internal water supply system, the roof surface is divided into approximately equal parts of 150-200 square meters each. In places with a slope, drainage funnels are installed, equipped with baskets for catching debris. Typically, funnels are located in the center of the roof, and the pipes are located inside the building.

Rules for insulation and vapor barrier of a flat roof

A flat roof needs insulation. In the absence of a layer of thermal insulation, condensation forms on the roof surface as a result of the contact of warm air masses and the cold surface of the roof. Condensation appears as water stains on the ceilings of the house, and the roof structure gradually collapses.

The roof design involves a base on which a layer of vapor barrier material is laid. The function of a vapor barrier is to protect the insulation from diffuse moisture coming from the premises of the building. The vapor barrier layer includes fiberglass reinforced membrane (based on bitumen and polymers) or vapor barrier film. The layer is laid on top of the screed, and along the edges of the roofing structure it is placed vertically to a height exceeding the height of the insulating material. The seams are sealed.

Insulation is placed above the vapor barrier layer, and a bitumen-based waterproofing carpet is placed on top of it. If expanded clay is used as insulation, then it is necessary to make a cement screed over it, then laying a couple of layers of waterproofing. If the roof is planned to be light (in the case where significant loads are not expected on it), then the waterproofing is simply glued along the entire perimeter of the roof.

For roofs without attics, both external and internal insulation methods are used. The external method is used more often, as its execution is simpler. There are two options for thermal insulation: double-layer and single-layer. The decision about which option to use in practice depends on heat engineering calculations and roof strength requirements. Thermal insulation slabs are placed on the roof structure based on the principle of “staggered seams”. With a two-layer coating of thermal insulation, the joints of the lower and upper slabs are also separated. In the area where the slabs adjoin the parapet, lanterns and walls, thermal insulating edges are created. Thermal insulation materials are attached to the base mechanically (screws, dowels), ballast (pebbles, paving slabs) or glue.

Features of roof ventilation

The roof structure must be equipped ventilation system. As a result of a violation of the tightness of the vapor barrier layer, moisture enters the insulating layer. A thick layer of waterproofing prevents evaporation from occurring, and moisture accumulates in the insulation. As a result, the material loses its insulation characteristics, and moisture appears on the ceilings of the building in the form of stains. In addition, water causes the waterproofing to swell, and at low temperatures, freezing water tears the waterproofing material away from the base. Temperature changes and mechanical damage contribute to the formation of cracks in the roof, which results in roof leaks.

To avoid these problems, the roof must “breathe”. For this, aerators are used - special devices in the form of plastic or metal pipes. They are covered with umbrella caps and are evenly distributed throughout the entire roof area, gravitating towards its highest points. The aeration mechanism works based on the principle of different pressures, which are created by air flows, removing excess moisture vapor from under the roof and preventing water bubbles from forming.

The installation of a roof is a responsible technological operation. Any, even minor, mistake in the design or construction of a roof can cause it to leak in the future. Therefore, when creating a roof you need to pay special attention correct selection hydro- and thermal insulation materials, accurately calculate the upcoming loads on the roof structure, and also select a team of competent builders.

By itself, a well-insulated roof truss made of wooden blocks cannot create the cozy atmosphere that arises under a monolithic roof. Reason: roof elements made of porous concrete or brick have not only thermal insulation properties - they accumulate heat. Thus, a monolithic roof is a good alternative to traditional wooden beams.

The most expensive part of the construction work for the construction of a monolithic roof occurs in the stage preceding the laying of the slabs. While in a timber beam truss support the worst-case scenario can be padded and the gable walls take their final shape later, in a monolithic roof there is hardly any room for correction at a later date. Therefore, when constructing the supports of a monolithic roof, you need to do the work very pedantically. Already determining the right angles of the horizontal projection requires a lot of effort. But if the building is characterized by sloping corners and balconies, then it is necessary to recheck the angles of the roof and the position of the ridge crest repeatedly and with mathematical precision.

It is best to pull the cords in the plane of the support of the slabs. Each block is first fitted dry and the line of curvature of the supports is marked. Cutting blocks is very easy and simple, especially if you build from porous concrete and have a band saw at your disposal.

If a reinforced concrete ring anchor is needed to support the slabs, the work can be difficult, since the connecting reinforcement is removed from the support, which then must fit accurately into the gaps between the slabs. In this case, the cooperation of a construction expert is recommended. The formwork for the ring anchor is made from thin blocks on the side. Then the reinforcement of the ring anchor is coupled with the connecting reinforcement and poured with concrete. Pre-wet the masonry walls. Advice: the static will calculate whether to build the support with masonry or make it concrete.

With a monolithic roof, supports and formwork are unnecessary

Once the monolithic roof slab supports are in place, you lay the precast blocks with two helpers and a construction consultant from the monolithic roof supplier. Within a few hours the roof is covered.

Roof slabs consist of reinforced porous concrete or reinforced brick elements, which have full load-bearing capacity already upon delivery. Therefore, with a monolithic roof, supports and formwork are unnecessary.

Typically, monolithic roof slabs made of porous concrete lie on the gable walls and load-bearing internal walls. Any roof slope and almost any span are feasible. But for production reasons, precast blocks can only have a maximum length of 6 m. If large spans are to be spanned, then reinforced concrete beams and steel I-beams are required, which you are already familiar with from porous concrete slabs (page 57). While reinforced concrete beams under the roof, like large lintels, cross the room and are visible, steel supports can be built into the plane of the slab and later completely invisible. In this way, monolithic roof structures are manufactured for almost every plan.

In a monolithic roof, you can also build windows into the roof plane. In any case, this is only done with a custom made steel frame. Such a steel building part in most cases rests on the side walls and serves as a reliable support for those roof slabs that were disconnected to construct a window in the roof plane. The larger the window needs to be, the more expensive the frame will cost.

Tip: Windows in the roof plane can be made from a steel frame near load-bearing internal walls running parallel to the gable, if the disconnected roof slabs respectively have at least two supports (on the gable and on the internal wall). The roof slabs are then laid as cantilever slabs (similar to balcony slabs, page 60), without the need for a steel frame. A self-build consultant can help you with detailed planning.

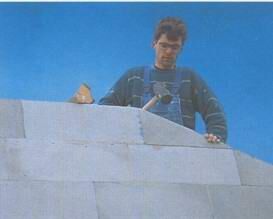

The support for the monolithic roof is being prepared: lay the blocks dry and mark the roof slope.

The sawn block is placed, as usual, on a thin layer of mortar.

Now prefabricated monolithic roofing blocks are delivered to the top by truck crane.

The easiest way to cover large purlins is with I-beams.

Custom steel frames allow windows to be built into the roof plane.

After laying the roof slabs, its edge is covered.

Support boxes with curtain shutters can be built into the ring anchor. Discuss the details with the static.

Steel rods should be placed in the gaps between the prefabricated slab blocks.

You can now concrete the ring anchor. Then fill the gaps with mortar.

Now they begin laying the wooden beams. Align the roof overhang with the cord.

Wooden beams are secured with bolts and nails in accordance with the calculation of static load parameters.

It goes without saying that a chimney sweep hatch can also be made into a monolithic roof. In this case, load transfer will help, which is already known from the construction of a pipe passage in a porous concrete floor.

Important: retroactive integration of a window into the plane of a monolithic roof is completely excluded. A monolithic roof (just like a floor slab) is a building block whose load-bearing capacity is guaranteed in a unified system for calculating static load parameters.

A reinforced concrete ring anchor is built around a monolithic roof

Now the roof slabs have been laid and the cladding of its edge begins. This work is familiar to you from the construction of floors from prefabricated blocks. From the inside, heat-insulating slabs are placed on the side blocks, then a ring anchor is assembled and concreted (use spacers and wet the masonry). Before the gaps between the slabs are filled with mortar, steel rods are placed in them. By the way, the ring anchor is also installed under the ridge of the roof.

Now it's about roofing works Oh. If the roof space is later to be used as a living space, additional thermal insulation is required. First placed edgewise on the roof slabs wooden beam. In this case, you need to choose a beam with cross section corresponding to the thickness of the insulating material: the beams must be at least 4 cm higher than the thickness of the insulating material. This space will later be used for ventilation. The thermal insulation thickness of a group with a thermal conductivity coefficient of 0.35 is from 5 to 8 cm (approximate values). Hint: ask your consultant how thick the insulation should be.

Let's return to the installation of wooden beams. There should be up to two connecting elements with a monolithic roof per meter of length. In this case, to facilitate the work, it is enough to make every third connection using dowels and screws. Other connecting elements are nailed. When in doubt, ask the static how the connections should be made in your case. Tip: Pre-drill the holes. Not only for bolts, but also for nails. Thermal insulation is laid between the wooden beams. The following steps are comparable to those for the construction of a conventional wooden truss: above wooden structure a film is laid, permeable to the diffusion of water vapor, which is reinforced with counter strips. A transverse sheathing is placed on top. Then a gutter is installed and the roof is made. The minimum distance from the slightly sagging underlying film to the thermal insulation is 2 cm.

Monolithic roof: options

A flat roof is still an unusual decoration for country cottages. It is believed that flat roofs are intended only for urban development or industrial buildings. But that's not true. The roofs of houses in historical neighborhoods are often pitched. And a private house can have a flat roof.

Now we will look at what it is, what are the advantages/cons and how to make a flat roof with your own hands.

Types of flat roof

Structurally, flat roofs are divided into two main types: those on beams and those with a concrete slab at the base.

Flat roofs are never completely flat; there is still a slight angle (within a few degrees). This is necessary for water drainage. Otherwise it will stagnate on the roof.

Most often, internal drains are installed on flat roofs: funnels are mounted in the roof, risers from them pass through interior spaces. Funnels are placed on the lower part of the roof, at the rate of one riser per 150-200 square meters.

The waterproofing around the funnels is reinforced; cable heating is also recommended (so that the water in the riser does not freeze). If the roof is flat without a parapet, and the angle is decent (from 6 degrees), the drainage system can be a standard external one, as for pitched roofs: gutter and pipes.

Roofs are divided according to functionality, roofing structure and type of coating. Here are a few main varieties:

- The unused roof is flat. It is erected solely for the sake of originality and economy of material. Does not require structural reinforcement.

- Operable flat roof. It can be used for any purpose, from placing an outdoor swimming pool to constructing a parking lot.

The type of floor depends on the intended purpose: it is obvious that for high expected loads, the base should be a concrete slab. But this does not mean that the entire building must be brick or concrete. For example, a flat roof in wooden house can also be exploited. Of course, it cannot be used as a helipad, but setting up a solarium, laying out a garden or putting up a gazebo for tea drinking is fine. Of course, you can’t make a sparse sheathing, only a continuous one.

- Traditional roofing. The classic design of the roofing pie: a waterproofing layer on top of the insulation, the base is concrete, for the outflow of water - expanded clay concrete (inclined screed).

- Inversion roofing. Here the insulation lies on top of the waterproofing and protects it from damage. The floor can be finished with paving or ceramic tiles, you can also plant a lawn here. A mandatory requirement for an inversion design is an angle of 3-5 degrees.

Roofs can be attic or non-attic. Both types have their advantages: the presence of an attic allows you to place all the necessary communications on it ( ventilation pipes, expansion tank heating, etc.), a roofless roof can be made usable.

One of the options for a roofless design is a flat combined roof: attic floor combined with the roof, the lower side is the ceiling in the living room.

Please note

The design of these roofs differs from simple attics; they cannot be used for use.When the height of the house is ten meters or higher, as well as on roofs in use, a parapet must be installed. For those in use - no less than 1.2 meters.

If the roof is not in use and the cottage is not high, you can make a flat roof without a parapet or install fencing bars instead, or even do without them.

General structure of a flat roof

It is obvious that roofs used for different purposes will have different structures:

The most common covering is a flat roof. It is cheap, simple and fast to install, with excellent waterproofing. The cheapest material that can be used to cover a flat roof is roofing felt.

The disadvantages of rolled materials (and roofing felt in particular) are low durability and low mechanical strength. For “high traffic” roofs, tiles are preferable.

A flat roof made of and a flat roof made of corrugated sheets can only be made in a non-operational version and with the required slope. When choosing a material, you need to read the instructions for the model: some types of corrugated sheets and metal tiles allow installation on roofs with a slope of less than 11 degrees.