Buleryan stoves with a water circuit. Features of installation with a water circuit. Main features of the oven

Selecting boilers for space heating this moment big enough. Each heating device has its own positive and negative points. Therefore, this choice should be taken quite seriously, because the costs that will be carried out in the future and the temperature in the room that you can maintain with the help of the boiler will depend on it.

Rice. 1The main characteristics by which a heating water boiler can be divided

The first characteristics that you need to pay attention to when choosing water boilers:

- Power.

- Fuel type.

The power of a water heating boiler is directly proportional to the size of the building itself. In this case, you need to calculate not only the area of the apartment or house, but also pay attention to the height of the ceilings. These are the main points that you need to pay attention to when choosing a heating device. But there are also additional factors to consider.

This is the thickness of the walls, the strength and size of the windows, and the materials used to cover the ceiling. If you plan to calculate the power required for your home as accurately as possible, then you can use additional programs, which were developed by many engineers in the heating field, and take into account as much as possible all the heat costs in the room and the necessary power to maintain a comfortable temperature for living and calculate the costs of heating work.

If it is not possible to use such services, then you can independently calculate the required power, however, these calculations will not be so accurate.

These coefficients are generally accepted for heating devices:

- When choosing heating equipment for a house without thermal insulation you need power from 130 to 200 W/m2;

- Old houses that were built about 20 years ago and used thermal insulation from those times require power from 90 to 110 W/m2;

- If your house is insulated using all new technologies, then a power of 50 to 70 W/m2 will be sufficient for heating systems.

The second characteristic that you should definitely pay attention to is the type of fuel and combustion period.

There are several types of fuel that heating systems can operate on:

- Liquid fuel– such fuel can be gasoline or diesel fuel, the burning period of which is quite short, and the heating power is not stable;

- Electrical. Long burning period, which is only possible with a continuous supply of electricity;

- Gas boilers, in turn, are made into two subtypes. The first is the use of main gas routes. And the second if there is a cylinder. A boiler that operates with a cylinder cannot have a long burning period, or constant monitoring and replacement of cylinders is required;

- Using solid fuel. A solid fuel heating boiler can have different periods combustion and heating power.

Additional characteristics that are used when choosing equipment

additional characteristics when choosing a boiler, they also have great importance and directly depend on the building itself in which they will be located. As well as the main and additional functions, which are necessary for the owners of the premises.

1. Material of manufacture

The materials from which the devices are made are cast iron and steel. Depending on the material, the method of its use may differ. Buleryan cast iron devices are quite reliable, but they are also massive and cannot be used in small buildings.

Such devices can be solid fuel and have a long burning period. The Buleryan steel apparatus is more convenient for small rooms, but at the same time its heat transfer coefficient is lower and hard material not suitable for him.

Rice. 2

Rice. 22. Equipment installation method

Depending on the building in which you will install the device, you should choose it. Boilers are divided into: floor-mounted and mounted. Floor-standing ones are generally larger in size and can be used for large rooms. They also have a long burning period and good heating power. One of the highest quality devices of this type is the Buleryan boiler with a water circuit.

Such a boiler often requires a separate building, so it fits well for big house, in which this room can be allocated. Such a device can be solid fuel and have good performance, which is necessary for a large room in a private house.

For small buildings you can use the Buleryan attachment. The power and dimensions of the thermal energy output of such devices are slightly smaller, so they are ideal for small rooms. Also, such boilers do not require additional, separate rooms for their placement and can have a long burning period. For such a building you can use a Buleryan water heating boiler.

3. Outlet circuits of the water heating system

According to these characteristics, the boiler can be single-circuit or double-circuit. Single-circuit devices are mainly used for only one purpose, heating rooms using a water system. A double-circuit heating device was created to save space and, in addition to heating the house, is also used to heat water.

4. According to the method of removing combustion exhaust

Based on the method of removing exhaust from the device, two types can be distinguished. This is forced removal and natural. Here you also need to start from the room in which the boiler will be placed.

If you have a separate room that can accommodate equipment, then you can choose natural removal of combustion products. But if the heating device is located in the living room, then it is better to use the forced method of removing combustion products.

Manufacturer's choice, Buleryan boilers

Rice. 3

Rice. 3There are quite a lot of manufacturers on the solid fuel boiler market who make a wide variety of products for different needs and for different buildings. One of such boilers is Buleryan. Their production is carried out using the latest equipment and in terms of price/quality ratio they are the best good options. Heating devices Buleryan is a market leader among manufacturers.

Can be used in a wide variety of rooms. Boilers long burning Buleryan, such as the Buleryan water boiler, has a good level of thermal output. Possibility to use solid fuel materials. Works on one circuit or two output circuits.

Among them you can find long-burning boilers Buleryan. Such boilers are divided into many options, among them you can find heating boilers, potbelly stoves, boilers and many other options for heating your home. Such devices can have a power from ten to one hundred W/m2. In addition, they have good performance over a long combustion period using a small amount of fuel materials.

If you have chosen a Buleryan solid fuel boiler, then one full load of solid fuel will be enough for you for four to eight hours, depending on the size of the building you will also have a good level of thermal output.

Technical base companies that manufacture Buleryan boilers except high quality workmanship and constant monitoring, can also offer its clients to carry out calculations required power to maximize thermal output and improve heating performance. This way you can choose the device as accurately as possible, satisfy all your needs, and serve for as long as possible.

If the room is large enough and exceeds the size of a thousand square meters, then it is recommended to purchase several Buleryan devices, which can simply be combined in one heating system, with output to one circuit. It is recommended to use a Buleryan solid fuel boiler; the power of such a system will be increased and will be able to efficiently heat the home using a water heating system.

To do this, you need to calculate the area, decide what type of fuel is suitable for you, and install the heating system using Buleryan boilers, which burn on solid fuel.

Most popular among consumers in Lately The Buleryan factory has solid fuel boilers that have a long combustion period using solid fuel. The power of such a device is not inferior to conventional ones. gas boilers Buleryan. The first thing you need to do if you plan to install such a boiler is to calculate the required power of the heating system.

Carry on further correct installation heating system and choose the fuel that suits you best. The Buleryan solid fuel boiler can operate on either one circuit or two circuits and use different fuels.

Buleryan boilers have a good level of thermal energy output and a long combustion period with a small amount of fuel. The Buleryan boiler was created to save money and time.

The heating unit, developed in Canada specifically for mobile teams of lumberjacks, has won recognition all over the world due to its high efficiency and safety in operation. The wood-burning stove Buleryan (bullerjan) is used today as a heat generator for air and water heating of private and country houses, outbuildings.

Stove Buleryan (Breneran)

Air heating furnace

The designers' task was to create a compact and lightweight solid fuel unit capable of quickly warming up a room. At the same time, it was important to ensure simple control of the stove operation, take care of safety - minimize the risk of accidental burns and prevent entry into the room carbon monoxide. Let's take a closer look at the structure and operating principle of Buleryan.

Design

The cylindrical or teardrop-shaped body of the stove is equipped with built-in curved air ducts. The main part of each pipe is located inside the housing and is heated by a flame. From the lower end of the pipes it is sucked cold air, in the process of moving up it has time to warm up. On average, the stove pumps 4-6 cubic meters of air per minute, quickly heating the room.

The combustion chamber is divided horizontally into three compartments. Fuel is placed in the central one, on the grate. Ash accumulates in the lower compartment. The upper compartment is separated from the middle by a metal sheet with holes - it serves as a secondary chamber for burning pyrolysis gases, and they do not burn completely there - the final combustion occurs in the chimney pipe.

The oven body is equipped with a hermetically sealed wide-format door. It is equipped with a pipe with a damper - the throttle allows you to regulate the intensity of fuel combustion by changing the amount of air entering the firebox. To regulate the draft force, a slide damper is mounted at the furnace outlet. The furnace operation is adjusted by changing the position of the dampers.

Design features Buleryan stoves

Design features Buleryan stoves Features of operation

The Bullerjan stove in its original design is equipped with an economizer - a device that allows you to burn pyrolysis gases in order to extract maximum thermal energy from the fuel. A heat generator with an economizer has an efficiency of up to 80%; without this device, the efficiency of the furnace is about 60%.

Secondary combustion of combustible wood gas occurs in the horizontal section of the chimney (from 15 to 30 cm), which is reliably thermally insulated with non-combustible material. Due to the accumulation of gases in this section of the pipe, the temperature of the medium rises and a flame regularly flares up, flammable gases flare up, increasing in volume. As a result, a gas plug is formed and without air access, combustion stops. The process is then repeated cyclically. The frequency at which gases flare depends on the oven setting.

The Buleryan air heating stove is completely safe - even if you leave the firebox door open, carbon monoxide will not enter the room. During operation of the unit, the metal body heats up to 50-60°C, so contact with the stove does not threaten a person with burns.

If you install air ducts, they can supply heated air to the adjacent room, providing air heating.

Firebox rules

Buleryan in combustion mode works only in the first stage - within 20-30 minutes after ignition. During this time, the room has time to warm up. The rest of the time, wood fuel should smolder, releasing flammable gases. If the unit is forced to constantly work in intensive mode, the metal casing will quickly burn out, while a significant part of the heat will evaporate with the flue gases.

Heating the premises with a Breneran stove

Heating the premises with a Breneran stove When lighting a stove, it is important to use dry, fast-burning fuel. During the ignition process, the throttle and gate valve must be open to ensure high draft. When the first load of fuel turns into coals, add large-format firewood or briquettes. Having placed firewood in the heated stove, it is necessary to close the damper and throttle, adjusting the air flow.

Attention! The Bullerjan stove is not designed to fire brown or hard coal or anthracite due to the too high combustion temperature of such fuel.

Unit installation

Installation of the Buleryan stove is carried out in accordance with fire requirements. It is important to maintain the distance to the walls, which depends on the surface material:

- not less than 1000 mm if the wall is wooden, without plaster;

- at least 700 mm from the wall with a 25 mm layer of plaster or ceramic tile cladding;

- not less than 500 mm from single brickwork or cladding from sheet metal 1 mm over 7 mm thermal insulation;

- not less than 300 mm from double brickwork or a panel mounted from two 1 mm metal sheets with a 30 mm thermal insulation pad.

Diagram of a thermal chamber for a heating unit

Diagram of a thermal chamber for a heating unit The base for the Buleryan stove must be non-flammable. A podium is laid out of brick or a sheet of steel is simply laid on the floor on top of a sheet of non-combustible heat insulation. Steel sheet 500x700 mm in size must be located in front of the furnace door of the stove for air heating.

Installation of the Buleryan stove requires proper installation of the chimney pipe, it can be:

- brick with a wall thickness of 120 mm;

- concrete with a wall thickness of 60 mm;

- metal - single or “sandwich”.

The height of the pipe depends on the power of the heating unit and is indicated in the product data sheet. Minimum height – 4 m, minimum cross-section – 120 mm. The chimney is allowed to be exhausted through ceilings and through a wall with the installation of a heat-insulated passage unit.

Water heating furnace

Buleryan with a water circuit (Breneran Aqua) is a modification of the already known stove, which is designed for operation as part of an autonomous water heating system for heating several rooms in the house.

If air heating installation is primarily intended for small country houses, garages, workshops and greenhouses, then Buleryan Aqua is a full-fledged boiler that is suitable for organizing heating of an individual residential building.

Principle of operation

Buleryan with a water circuit is similar in design to air option stoves, but in this case the coolant circulates through the pipes surrounding the combustion chamber.

Breneran furnace with water circuit

Breneran furnace with water circuit The boiler functions as follows:

- the ends of the pipes for convection from above and below are connected in unified system using collectors;

- the upper collector is equipped with a pipe for supplying heated coolant to the heating system, the lower one is for connecting the return pipe;

- when heating the coolant in the heating circuit, a pressure sufficient to natural circulation with the liquid rising to a height of up to 8 m, this allows for the supply of thermal energy to heating devices, connected to the circuit;

- the cooled coolant enters the lower collector.

Breneran Aqua also works with wood fuel; thermal energy is obtained through direct combustion of fuel and combustion of pyrolysis gases. Combustible gases are burned in two stages - the main part in the upper chamber of the firebox, the remaining in the economizer, which is equipped with the chimney.

The most energy efficient fuel for Aqua Breneran is firewood. The use of peat briquettes and pressed wood waste is allowed, but their thermal output is lower.

Advantages and disadvantages of the unit

Buleryan with a water circuit has a number of advantages over a heat generator of the same type, but for air heating and other units:

- there is no need to lay air ducts; heating radiators serve as heat sources in the premises of the house;

- a boiler of this type can be installed in houses without a basement, there is no risk of carbon monoxide entering the room;

- Heat-resistant materials are used to manufacture the unit, which increases its durability;

- the stove can be used in a water heating system with natural and forced submission coolant;

- installation of equipment is carried out in a short time, it is possible to additionally use a system that prevents freezing of the heating circuit.

Breneran Aqua with water heating circuits

Breneran Aqua with water heating circuits The disadvantages of Aqua Breneran include:

- inability to use the oven without connecting to the water circuit;

- errors in the installation of the chimney, the use of insufficiently high-quality fuel, and incorrect selection of the stove operating mode lead to a decrease in the thermal efficiency of the unit and the formation of condensate, which contains a whole range of harmful substances.

Installation features

In accordance with fire safety regulations:

- The oven must be mounted on a solid base made of non-flammable material. For some models of the unit, a concrete base is required.

- The floor on the side of the combustion chamber door is covered with a metal sheet at least 1250 mm in length.

- The distance to walls with a plastered surface is at least 1000 mm, with additional insulation - 800 mm.

- The area of the room where the stove is installed must be at least 12 m2.

- The room must be well ventilated.

- It is mandatory to use a safety group when connecting a heating circuit.

Rules for installing Buleryanov

Rules for installing Buleryanov Connection to the heating system

If Buleryan with a water circuit is connected to gravitational system heating, then for effective coolant circulation you need:

- install the stove 0.5 m or more below heating appliances;

- install the pipes at an angle towards the direction of fluid circulation;

- place at the top point of the contour expansion tank, the capacity of which is selected depending on the volume of coolant in the system;

- mount the safety group on the pipe supplying the heated coolant.

Attention! When calculating and installing a pipeline, it is important to observe optimal angles tilting the pipes to ensure normal coolant movement and avoid the formation of air pockets.

If the stove is used as part of a system with forced coolant supply, it is necessary:

- mount circulation pump on the return pipe, through which the cooled coolant enters the lower manifold of the furnace, between the boiler itself and the expansion membrane tank;

- install a UPS with a voltage stabilizer to ensure uninterrupted operation of the circulation pump;

- install a temperature sensor to be able to monitor temperature conditions and pressure in the system;

- install a boiler safety group that will allow you to maintain a pressure level in the circuit of no more than 7 atm.

Diagram of Buleryan's device with a water circuit

Diagram of Buleryan's device with a water circuit Piping and coolant

For piping Breneran furnaces with a water circuit, pipes from various materials, when choosing, you should take into account their operational properties and installation features:

- Steel pipes . Resistant to overheating, different low coefficient linear expansion, high strength and thermal conductivity. The disadvantage is the need for welding when installing the pipeline, large inner diameter pipes

- Polypropylene pipes. Lightweight, durable, not subject to overgrowth and corrosion, and can be quickly installed. Disadvantages: they greatly increase in length when heated; installation requires a special tool.

- Metal-plastic pipes. They are not subject to corrosion and overgrowth, are quickly installed, and are resistant to heat. Disadvantage - they break when the permissible bending radius is exceeded.

Polypropylene pipes and fittings for piping the heating system

Polypropylene pipes and fittings for piping the heating system The coolant in a heating system based on a Breneran heat generator with a water circuit can be ordinary or distilled water, an anti-freezing liquid.

Water is a cheap and accessible coolant. Its disadvantages include the property of freezing at temperatures below zero degrees. It is recommended to pour water into the system if it is designed for non-stop operation during the cold season. Water with a high content of metals cannot be used as a coolant. It is advisable to install a system for filtration and water treatment. Installing a special heating element will help avoid problems associated with defrosting the water circuit.

Antifreeze liquid is suitable for heating systems that winter time been used intermittently for years. The use of antifreeze allows the system to survive a drop in temperature in the house to -20°C. The disadvantages of antifreeze include high turnover– increased requirements are placed on the tightness of the circuit. In addition, the cost of antifreeze is much higher than the cost of water. To calculate the monetary investment in the purchase of an antifreeze coolant, you need to calculate the volume of liquid in the system. To do this, the volume of the pipeline, all radiators and the water circuit of the furnace is summed up.

Conclusion

The type of Buleryan stove is selected depending on the needs - for country house or utility buildings, it is easier to use an air-heated unit. In a house with several rooms, including on different floors, it is more convenient to use a Breneran boiler-stove.

The main advantage that the Buleryan (buler, breneran) stove has is instant heating of the room with low economical fuel consumption, and then maintaining the temperature for a long time. By appearance they resemble ordinary “potbelly stoves”.

What features do bullers have?

The units are installed in garden houses, garages, greenhouses, workshops, places where there is no natural gas, electricity.

They can operate, providing combustion in smoldering mode for up to 10-12 hours, on wood, as well as wood products: dry pellets, briquettes, wood chips, paper, cardboard.

Whose invention is this?

Canadian heating engineers were tasked with developing a furnace for logging crews that would run on waste material: branches, cones, sticks.

The firebox had to accommodate wood of a non-standard configuration and warm up the home in a maximum of 10-20 minutes.

According to the requirements, according to the drawings, a mobile device was created that operates like a heater, is safe, and easy to operate.

Structure

Structurally, the Buleryan slow burning stove is an oval sealed barrel-shaped boiler. The main feature is the presence in the body of two rows of air pipes, between which metal (usually steel) strips are welded. The tubes are bent in the shape of a parabola and are immersed in the combustion chamber by two-thirds of the diameter.

The large round door is equipped with an air supply regulator in the form of a pipe with a smoke damper (throttle). A window with heat-resistant glass allows you to control combustion. On the throttle handle there is a scale with degrees and a movable stop limiter.

By stopping the draft, you can change the power of the buller, extinguish the fire, and prevent the room from getting cold.

The heating chamber is divided into three parts. At the bottom there is a grate made of cast iron or steel, the upper partition in the form of a sheet with holes separates the afterburning zone. There is no ash removal tray as it is unnecessary. Ash particles fly out through the chimney.

There is an exit with a flap on the back wall. The gaps on it do not allow carbon monoxide to enter the room even when the door is open. The pipe is connected to the chimney by a horizontal section in which unburnt pyrolysis gases cool.

How does heating occur?

The operation of the device is based on forced convection heat exchange. After ignition, cold air is sucked in through the lower openings of the air ducts, quickly warms up, and exits in a hot, intense stream from the upper opening. It is smoothly, evenly distributed throughout the room, cools, and falls down. The unit, which combines three devices at once: the Buleryan stove itself, a heater, a gas generator, operates in two modes:

- Kindling, which provides quick heating to 120-150º C.

- Gasification that maintains smoldering of firewood at a level of 50-55º C.

Unit properties

If you calculate the costs of gasifying a facility, the cost of registration necessary documentation, the economic efficiency of the Canadian invention becomes obvious. At correct operation the equipment will last forever.

pros

Ease of use due to the fact that special training is not required for operation. The closed fire system has the following advantages compared to potbelly stoves and fireplaces:

- the boiler does not heat up and does not “eat up” oxygen;

- two-chamber firebox and secondary air supply provide high efficiency up to 80%;

- no permits are required for a water loop system;

- long period of work on one full bookmark;

- has several standard sizes with a power of 6-35 kW;

- capable of uniformly heating from 100 to 1000 m³;

- You can install a Buleryan stove with your own hands.

During installation, it does not require additional reinforcement of the floor. It can be transported from place to place without inconvenience during transportation.

Minuses

Need for constant maintenance, cleaning the chimney is caused by the fact that the device runs only on solid wood fuel. Besides:

- mandatory pipe insulation is necessary;

- the body should be located far from the wall;

- requires a lot of space;

- produces a lot of smoke at the exit;

- accumulates condensation.

In rooms separated by partitions, the efficiency of this type of heating is reduced. There is a need to arrange a water “jacket”.

System with radiators

The design of the boiler with a water circuit is identical to the buller. Only it is not the air that is heated here, but the water or antifreeze. Circulation is carried out naturally or forced. The coolant liquid is supplied to the top point of the system, directed to the radiators, then along the return line to the stove, where a drain valve is installed.

When installing such a system, the unit can be installed anywhere in the building where the chimney can be removed. It is important to maintain a minimum distance to the wall - 0.5 m. For the water circuit it is better to use reinforced polypropylene pipes, which do not deform from high temperatures.

Before start-up, pressure testing and adjustment work must be carried out.

Homemade boilers: are the savings real?

In order to assemble a Buleryan stove with your own hands, you do not need expensive equipment or special alloys. It can be made from pipes with a diameter of 5-6 mm, sheet metal with a thickness of at least 2.5 mm, even from an old gas cylinder. Calculation of footage and area of workpieces is carried out according to drawings and diagrams.

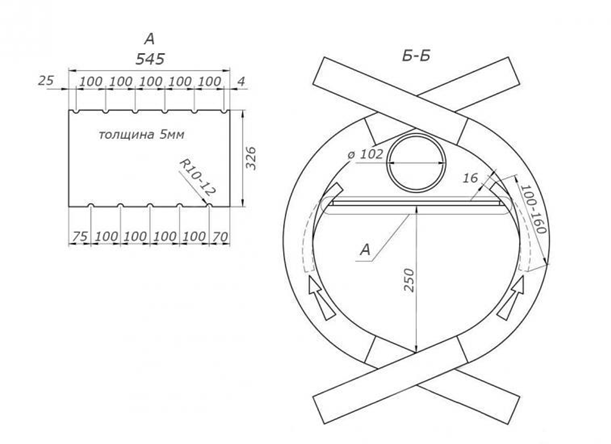

Schematic representation of the device:

Buller drawings are given at the end of the article.

With absence necessary tools and accessories can be rented for a small fee from a repair shop:

- welding machine;

- electrodes;

- grinder;

- metal scissors;

- pipe bender;

- angle grinder.

A hammer, ruler, angle, pattern, level, bars, the thickness of which is equal to the diameter of the pipe, will be useful during the assembly process.

Step-by-step instruction

The tightness of the chamber depends on the quality of the seams, so an inexperienced craftsman should practice and check the material for weldability. You can take the drawings of a small stove for small utility rooms as a basis and increase it to the required size.

Cutting parts, forming blanks

We cut 8 pieces from the pipe from 1 to 1.5 m long. From the sheets we cut out ribbons with semicircular notches at the ends.

We bend air ducts at an angle of approximately 80º. We bend the metal strips at the same degree.

Assembly and welding

We lay curved convection pipes with the outlet part facing outward in a checkerboard pattern, starting from the back wall until reaching the front level. For stability, we place between them wooden blocks. We level the structure. We grab with spot seams at the mating nodes.

In inner part We weld the pan horizontally onto the body body. To remove combustion products, it is better to make grates from two halves connected at an angle. First we grab it pointwise, then we go through the entire plane continuous seam. We insert bent steel strips between the pipes and weld them.

First you need to make a pattern. We attach the cardboard to the side and trace it with a pencil. We cut out a part from sheet metal along the contour. We cut out a loading window on it with a diameter of half the wall, shifting the center slightly below the axis. We weld a 40 mm wide strip around the outside perimeter of the window for a short “collar”.

We make the back wall in a similar way. We cut a hole corresponding to the diameter of the outlet pipe in the upper part of the circle. We insert a T-shaped section of a 100 - 110 mm pipe with a valve into it and connect it to the body. We put the walls in their places.

Door

The fire door is a short cylinder that must fit precisely onto the “collar”, falling into the gap between the outer and inner rings. To improve the sealing, you need to drive an asbestos rope between the rings.

We cut out a hole in the blank for the blower and weld a pipe with a throttle valve. The damper can be made by cutting the walls of the pipe along the axes. We take a pin, weld a flat disk onto it, and insert it into the perforation of the pipe. On the inside we install a semicircular heat-reflecting screen on metal spacers. We hang the door on its hinges and install a lock. We make them from scraps of sheets. You can buy ready-made parts.

In order for the stove to be located at a sufficient height from the floor, we bend the legs from the remains and weld them into the body in the places indicated in the drawing. After cleaning and cosmetic sanding of the surface, the structure is ready for installation.

Russia is one of the largest countries in the world, whose territory is located in different climatic zones. That is why we have to deal with the heating problem in different ways. In those regions that are heated with wood, you can often see Buleryan solid fuel stoves with a water circuit. Such a stove can only be heated with wood and it is not recommended to use any other type of fuel. After all, complex chemical and physical processes occur in the device. Their normal course can only be ensured by dry firewood during combustion. Thus, when choosing this stove, you need to find out the cost and availability of fuel in your region.

Operating principle of the furnace

It should be noted that the idea of creating buleryan belongs to Canadian lumberjacks. They, in turn, shared it with engineers, who brought their ideas to life. The oven consists of a round body, which its shape resembles a barrel, inner space which is divided into two parts. In the lower part of the stove, ignition and combustion of wood occurs. In this same section, high temperatures are formed and a large amount of heat accumulates.

It should be noted that the idea of creating buleryan belongs to Canadian lumberjacks. They, in turn, shared it with engineers, who brought their ideas to life. The oven consists of a round body, which its shape resembles a barrel, inner space which is divided into two parts. In the lower part of the stove, ignition and combustion of wood occurs. In this same section, high temperatures are formed and a large amount of heat accumulates.

After the wood burns out, hot gases appear and fill the second part of the boiler. Several curved pipes run through the center of the two fireboxes. Here the convection method occurs, thanks to which a person uses heat for his own benefit.

Cold air enters the Buleryan through pipes. The air in the firebox meets the hot circuit, and as a result, a fast flow is formed, which rushes out and takes the heat of the furnace with it. This device does not have a fan, so heating occurs quickly. The oven uses 3 heating methods - heat exchange, heat transfer, convection.

The oven works in a special way:

- First you need to warm up the boiler with wood chips;

- the lower throat is filled to the very top;

- the firewood smolders for 12 hours. Then wood gas is formed, which highlights thermal energy in larger quantities;

- an air flow is formed that can reach up to 120 degrees Celsius;

- this air escapes through the pipes, allowing the room to heat up quickly without overloading.

It is worth noting that in the second firebox the gas cannot burn completely, even if there is good draft. That's why it's worth installing high-quality chimney. He must not have any defects, even the smallest ones, as this threatens the leakage of carbon monoxide, which is dangerous to the human body. If you have never installed a chimney before, it is best to entrust this task to professionals.

Features of installing a Buleryan stove with a water circuit

It should be noted that there were times when wood stoves could not compete with central systems heating. The thing is that a brick oven with wood couldn’t heat a large room, divided into rooms. Everything changed from the moment when engineers managed to combine a conventional wood-burning stove with a water circuit.

Today, even a Buleryan oven can be equipped with a circulation system. The coolant will move along it. Such innovations received the prefix “aqua” to their name. In this regard, devices such as “Aqua-Beleryan” and “Brenneran-Aquaten” appeared. Such installations can be used to organize a water heating system.

In a furnace, the water circuit occupies about 70% of the entire combustion section. That is why water heats up quickly and evenly. At the same time, heat loss is insignificant. In such devices there are no large pressure and temperature differences. If we compare the efficiency of the furnace, then the efficiency of gas generators will be on par. It should be noted that air circulation received huge demand. That is why such an installation is not uncommon in residential buildings, as well as in production premises enterprises.

It is worth noting that Buleryan stoves with a complete water circuit can produce heat for 12 hours. During this time there are no temperature fluctuations. This feature allows for a long time Do not re-fill firewood.

Advantages

Today's installations allow the room to be heated quickly and evenly, even if the room large area. If you choose an installation with a water circuit, the heat is easily transported to the rooms located on the second and third floors. The installation is compact in size.

It is very convenient to use this installation. Installation is quick and easy. But in order to install a chimney, you need to hire professionals.

It should be noted that the Buleryan oven do not consume a lot of fuel compared to other installations. One load is enough for 12 hours.

Of course, such a list of positive features in technical specifications, gives optimistic hopes. But still, in order for the picture to emerge completely, it is necessary to pay attention to the shortcomings of the installation.

Flaws

It is not recommended to load wet wood into the stove. Do not use firewood that produces resins when burning.

It is not recommended to load wet wood into the stove. Do not use firewood that produces resins when burning.

The generator gases in the Buleryan burn about 70% in the second furnace. That is why the installation cannot be called perfect.

When installing a chimney, special attention should be paid to its insulation. If this is not done, what condensation will be released, which reduces the performance of the furnace.

The main structural element is the body. Very often it is made of metal. The main source of heat is the boiler. That is why the space around it must be protected. It will be very difficult to protect the space if the buleryan is installed in the corner at the junction of two walls. It is not recommended to install the stove close to a wall. This ban is a big problem for small houses. There should be a maximum distance of 20 cm from the wall to the installation.

If you want to save space, then you will have to cover the walls with metal sheets. Their height must exceed the height of the installation body itself. In this case, you will have to lay it between the sheet and the wall. basalt insulation. In this case metal sheets will perform several functions at once:

- protection of walls from heating;

- additional source heat.

It is also worth noting that dust will constantly get into the pipe opening. When the stove burns, a temperature is formed in its channel that is capable of surviving everything in its path. Thus, unpleasant odors will often come from the equipment.

It must be said that near the furnace in operating condition charged ions are formed, which are capable of attracting small particles of dirt. They can enter the human body. If a person's immunity is weakened, this can lead to illness. In this regard, rooms heated by such a stove must be cleaned and ventilated every day.

If you want to buy such an installation, you need to pay attention to what material the boiler doors are made of.

There is a stove with a metal door, it looks beautiful, especially since you can see the fire burning through it. But at the same time, you can only see it when the firewood is burning. In other cases it is useless. Moreover, ovens with such a door have a higher price than usual. Experts do not recommend overpaying, but buying a regular oven with a metal door.

Installation cost

Furnaces with a water circuit are a production famous company Breneran. Such installations operate on the principle of gas generation and are designed for heating both small and large rooms. The price for them may vary: from 13,225 to 46,285 rubles.

As a rule, this company produces two types of installations:

- AquaTEN;

- Aqua.

The difference between these models and others is that they use heating element boilers and are notable for their design.

Any private residential building needs heating system.

Sometimes gas supply to the house technically is not feasible, and installing a boiler with documentation is difficult and costly.

Use of heater ovens ineffective, if you need to heat several adjacent rooms, since heaters are designed to heat an undivided space.

In such cases, the oven Buleryan Compared to analogues, it is an indispensable universal solution.

The idea of a new heating stove was born at Canadian lumberjacks, which was then brought to life by the engineering ideas of energy designers. Now the name of the furnace is Buleryan ( Bullerian) has become almost a standard, i.e. bringing warmth and comfort.

Principle of operation

This design is not only successful hybrid potbelly stoves with a conventional stove If previously they were not able to heat separate rooms, then the connection with a water circuit opened up the possibility of heating entire houses, rather than individual rooms.

The shape of the Buleryan stove resembles a large round one barrel, internally divided into two parts. The lower compartment of the stove body is designed for igniting and burning wood. It is also formed there heat and heat is concentrated.

After the wood burns, the gases rise into the upper compartment of the housing. In the center of the oven are welded into her curved pipes, or as they are called, radius pipes

They provide forced convection, i.e. moving heat to warm the air and distribute it evenly throughout the space.

The design of the stove is such that the pipes tightly fit the firebox with firewood, “ wrapping» her on 70% . They play the role of a heat exchanger or heater, since all the heat from the combustion chamber is used to heat the coolant in the pipes.

A specially installed pressure manifold provides required pressure for the movement of fluid other than its natural circulation.

Thus, the basic principles of operation are heat exchange, heat transfer and convection. Unlike the known oven surface doesn't get hot, which means oxygen is conserved.

Buleryan with a water jacket

New modification with a water circuit is manifested in the connection of pipes with a water heating system at the top - to the water supply, and at the bottom - to the return manifold.

Thus, the oven, as a heating element, receives hydropiping or additional features distribute heat through movement hot water through pipes surrounding the living space.

Buleryan can be compared with solid fuel boiler, but without automatic system. The design of the stove allows the connection of several water circuits for maximum heating of various rooms.

Due to active water circulation in the connected radiators, perfect, cottages or dachas.

Buleryan aqua- a modification of the good Buleryan stove, in which the water jacket enhances the overall performance. The stoves of this group are connected to a heating system, in the upper part of which there is an expansion tank for storing excess heated water.

Water in its movement passes through radiators, after cooling down returns to the chimneys.

Connecting the stove to the heating system

General scroll The elements of the entire heating system with the stove are as follows:

- stove buleryan,

- pressure manifold,

- return manifold,

- radiators,

- water drain tap,

- expansion tank.

Boiler installation

If the installation of gas boilers is related to permitting documentation and the involvement of specialists, then installation Buleryan stoves can be produced independently. He's enough simple And available.

To ensure safety, the stove must be installed on a durable, heat-resistant, non-flammable base, taking into account the distance to the walls of at least 70 see Connecting the water circuit and chimneys produced welding or threaded connections.

Warming up water can reach 90 degrees, so the site is installed boiler must be placed separately with limited access for children.

Chimney outlet

Requires special attention chimney. Perhaps this is the most vulnerable spot in the installation of the furnace. The fact is that even with good draft, the gas does not burn completely.

Needed here consultation and assistance from a specialist due to the high risks of carbon monoxide poisoning.

Important conditions correct installation and operation of the chimney:

- installation at a height of at least 3 m above the stove, in accordance with fire safety rules;

- periodic cleaning from soot settling on the walls.

Can be used for thermal insulation layer of mineral wool.

Fuel consumption

A remarkable feature of the oven is economical fuel consumption. You should use only dried firewood that does not form resin during combustion.

Chips or firewood burn out at high efficiency, leaving virtually no ash. Two full loads of the firebox provide heating for a day in the room. 60 sq.m.

The door, or flap, simultaneously serves blower, regulating the speed and air flow to increase the heating temperature or maintain combustion.

The furnace boiler allows for a long time retain heat, and the heat transfer period increases.

Important: The heating power of the boiler depends on the volume of the firebox.

General advantages of a water loop oven

The undoubted advantage of the stove is its ability to installations to the existing heating system without replacing old radiators, affordable price, and Also:

- compactness,

- possibility of transportation to different floors of the building,

- ease of operation,

- high efficiency,

- fuel economy,

- quick return on investment for purchase and installation,

- possibility of making a furnace And installation with your own hands.

Flaws

A less than aesthetically pleasing appearance requires additional effort. optimization placement of a mini-boiler room. It is necessary to provide for a separate location of the boiler and take into account following:

- V small houses you will need to sheathe the walls metal sheets to install the stove as close to them as possible,

- if you don’t light the stove in cold weather, there is a risk of the coolant freezing. The use of antifreeze or special additives is recommended.

Convenience and ease of maintenance of the furnace have been time-tested from the period of invention to the present day. Consumers note that when operation:

- room, in which the oven is located, need to be ventilated daily due to the formation of charged ions that attract dust,

- Do not light the stove without checking the presence of water in a system with a water circuit and the condition of the expansion tank.