Racks Made of Wooden Bars: Manufacturing Instructions. Do-it-yourself rack - creating storage space easily and simply (62 photo ideas) How to build a rack out of wood with your own hands

Cleaning up even a small room is not as easy as it seems. Especially if it's cluttered big amount of things. Help clear space and organize chaos spacious racks. The design is universal in its essence - it can be installed in any room, and it will look organic. To learn how to make a rack with your own hands, you need to understand the types and materials of this design.

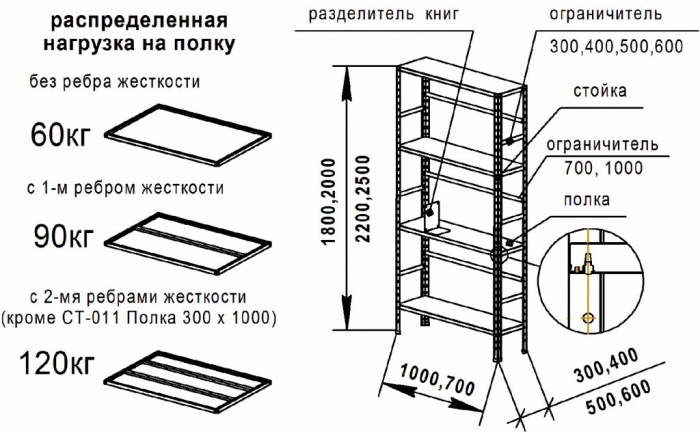

When hearing the word rack, many people imagine a simple metal structure, used primarily in warehouses. But such furniture is used only on a production scale or in garages. They must meet the following indicators:

- high functionality: the larger the capacity, the better;

- strength - best racks for storage rooms and garages, metal, they are durable and unpretentious;

- easy care - furniture made of porous materials or an expensive paint coating requires delicate handling, so in technical rooms It is better to use wood and similar materials.

However, the racks in living rooms I want to make it more original. You shouldn’t limit your imagination when creating such designs. Indeed, in addition to its main function, the rack can become a worthy decoration of the entire room.

Bottle rack

If you want to build a shelving unit for your kitchen, you should take a closer look at the bottle design. It will appeal to collectors and alcohol connoisseurs. To create a rack, use solid wood and bottles of the same shape and height. To give wood a noble shade, various impregnations and stains are used.

Note! Dark wood looks very noble with green glass bottles. And you can give the wood a vintage touch using artificial aging and firing.

Rack ladder

In large houses or two-story apartments, stairs take up a lot of space. To save money usable space this interior detail can be combined with a shelving unit. Hollow drawers made of solid wood or particle board materials can hold a lot necessary little things. Many book lovers store their favorite volumes in such cabinets. And the stairs are used as a cozy seat when reading. For more functionality The drawers can be supplemented with original doors.

If you already have a staircase in your house, and you do not intend to redo it, then the shelving can be placed directly under it. Create a structure that follows the outline of the steps. The distance between the vertical posts of the frame should be equal to the width of the steps. This will create an organic composition.

Suspended structure

For those who don’t want to spend a lot of time and money on a rack, it’s suitable suspended structure. It consists of shelves strung on twine. For storage heavy objects They don’t use it, but it’s fine for small trinkets.

Glass shelves look very interesting in this style. Shelves made of colored and transparent glass are strung on metal cables, and beads or decorative supports are strung at the distance between them.

Steampunk furniture

Fans of the steampunk style will appreciate the rack made of water pipes and fittings. The frame of the structure is assembled from them, and a solid mass is used for the shelves. The rack will organically fit into interiors in the style of:

- loft;

- steampunk;

- industrial, etc.

However, if you keep the furniture in subdued colors, it will perfectly complement both the kitchen and the living room. Rack similar type It also saves space thanks to the absence of rear pillars. The structure is attached to one plank on top and to the floor. The shelves are strung onto the racks one by one. Even an untrained person can assemble such a rack with his own hands.

Note! If you want to create a steampunk style structure, use copper paint for the frame.

Creating a Project

Before you start work, outline appearance and parameters future design. A piece of paper or design editors are suitable for this. Before constructing a drawing, you must consider the following parameters:

- the height and width of the room in which the rack will stand;

- size and weight of items given for storage;

- room humidity level.

The design of the rack is very simple: it consists of a frame and shelves. Wood and metal are most often used as the external frame. If the rack will be located in a room with high humidity- moisture-resistant wood species, plastic or glass are used for shelves. The metal frame is coated with anti-corrosion compounds to protect it from rust.

Important! In rooms where contact with moisture cannot be avoided, it is not recommended to use wood for the frame.

When you have decided on the purpose and location of the future rack, you can start taking measurements. Measure the height of the items that are planned to be stored on the shelves and add another 7-10 cm to the value.

Consider proper weight distribution. The heaviest and most voluminous items are placed on the lower shelves. The higher the shelf, the lighter the things stored on it should be. Various drawers, boxes, etc. are placed at the very top.

For racks on which books or jars with blanks are planned to be stored, the legs should be placed close (half a meter ± 10 cm). If a metal profile is used for the frame, the step is increased to a meter.

Creating a simple shelving unit from wood and metal

If you need simple and spacious shelving for your dressing room or pantry, use simple design made of wood and OSB. A square beam with a side of 5 cm or more is suitable for the frame. If you are ready to spend more money on the structure, replace the OSB boards with solid wood.

Assembly steps

The instructions for creating a rack include the following steps:

- cutting timber - the material is cut for the frame according to the drawing;

- using self-tapping screws or nails, a rectangular frame is assembled, assembly begins from the bottom corner;

- the frame is attached to the wall using metal fasteners and self-tapping screws;

- mark and saw OSB boards for future shelves;

- The shelves are laid on the cross members of the frame and secured with nails or self-tapping screws.

Note! Self-tapping screws are more durable fasteners.

Crossbar location

If the vertical posts are located close to each other, the design does not require crossbars. This function will be performed by a thick OSB board. If you want to create a more stable structure, you cannot do without crossbars. To do this, you need to install longitudinal crossbars under each shelf. You can get by with one, but most often they use a pair of crossbars.

Important! To increase the strength of the structure, diagonal beams are attached to the rear wall.

Metal rack

To assemble a metal rack you will need welding machine or electric drill. The welded structure looks neater, and it is also more reliable than the prefabricated one. If you do not have such tools, it is better to give preference to wooden furniture.

The instructions for assembling a metal rack are practically no different from making a wooden one. The first stage consists of assembling the frame and attaching the structure to the wall. If heavy materials are used for shelves, then crossbars are not needed.

Note! To create a rack, it is better to purchase a metal profile rather than a corner. It is more convenient to assemble and maintain.

A tubular metal profile is used as a material for slaves. square section with a side of 25 mm and a metal thickness of 2 mm. If a corner is used, the optimal size is 40 by 40.

For making light structures use supporting metal brackets. Dowels or self-tapping screws are used as fasteners. Shelves are laid on top of the brackets.

A lightweight version of the design can be made using metal support brackets. They are fastened with dowels to the wall, and shelves made of boards or OSB boards are placed on top.

If you want to know more about making a rack, watch the video instructions. From it you will learn the tricks of construction and will be able to assemble a durable and functional structure.

If your home does not have storage space for any group of items, be it books, work tools, etc., then you probably had to deal with the fact that as their number increased, the apartment gradually began to become cluttered. At first glance, it’s quite simple to arrange a storage room or additional wardrobe, however, owners of small apartments do not always have this opportunity due to lack of free space. How to organize things in this case? The simplest and practical solution Arranging a wooden rack with your own hands will solve this problem. But this is far from the only case when shelving for the home, including wooden ones, can be useful. The use of a rack is appropriate both in the garage, which without proper systematization of the space often turns into a dump of things, and on the balcony, where it will help to place seedlings or indoor plants in the most compact manner. Also, with the help of a rack you can zoning the space. Despite the fact that arranging a rack does not cause difficulties and is accessible even to a beginner, in this article we will describe in detail how to make wooden rack with your own hands.

Using shelving: main types

A wooden rack is a spacious structure made of wood, consisting of a large number of shelves, which are mounted on special racks. Moreover, the number of tiers depends only on the individual preferences of the owner. A prefabricated wooden rack can be used to store various items: books, dishes, tools, etc. It will fit perfectly into almost any interior, be it country or classic. The functional purpose of the premises in which a wooden shelving would be appropriate is also diverse.

- They will look most harmonious in a children's room, where, thanks to the presence open shelves, children will be able to conveniently place their toys and subsequently have free access to them;

- The functionality of an office or library can also be expanded with wooden shelving, which can be used to store books, documents and any important small items;

- Often, the rack complements the interior of the kitchen, where some housewives place dishes, cereals or spices that are used daily.

- An integral point of using wooden shelving is their use for arranging indoor plants and seedlings. In this case, you need to know a little trick known to professionals. It is known that most indoor plants, like seedlings, need barely perceptible heating of the soil, which will promote efficient growth and life activity. To implement this principle, modern manufacturers offer expensive racks with automation, which can easily be replaced by laying wooden shelves foam plastic shelving. This unique material, being an effective heat insulator, is able to reflect thermal radiation that is formed in moist soil, returning it to the pot and thereby implementing the principle of minimal heating.

Structural types of wooden shelving:

- Stationary rack. Its design is a frame consisting of racks and crossbars, on which a sufficient number of shelves are fixed. To increase the reliability and strength of a stationary wooden rack with your own hands, the photo of which is presented below;

- Mobile racks - constructive option, most suitable for those who cannot decide on their location. Due to the fact that such racks are equipped with wheels, there is no need to unload the contents while moving them;

- Rotating racks- a design that is suitable for storing various small items needed in the household: spices, dishes, hygiene items used daily;

- Hanging racks- a design that allows you to optimize space and use it rationally in the future. It consists of several shelves combined into a single structure.

Original options for installing wooden shelving

Many people believe that a shelving unit is a rather primitive design, consisting of a rough frame with shelves. However, such options are used mainly on the balcony, in the basement or garage, where the furniture in use must be durable and practical, while for residential premises experts recommend giving preference to more original designs. For example, a rather nontrivial construction for home interior there will be a rack consisting of a pair of oak boards and several glass bottles installed as shown in the photo below. And if, at first glance, the structure does not seem stable enough to you, cast aside all doubts and feel free to exploit it to the maximum, storing not only books, but also layouts of collection wines.

No less original are rope racks, for fastening them, unlike traditional frame structures, you only need two hooks on the wall. Of course, you won’t be able to store heavy jars with winter preparations on them, but you can easily arrange photographs, souvenirs, books, dishes and other small items. Rope racks, being temporary structures, can also be used for premises to be renovated. In this case, it is enough to make a structure from scraps of sedges or laminate, attached to a rope suspension. Fastening the structure will be easier if in the room where it will be located there is a heating pipe running under the ceiling - it will be enough to tie a rope to it.

Using the following advice, you can make an equally original wooden shelving unit without a back wall, which will be a successful addition to an industrial-style interior. To make it you will need not only wooden boards, but also a couple of water pipes and fittings. It is necessary to pay attention to original way installation of shelves - in this case they are “attached” to the pipes like a children’s pyramid. Thanks to the high rigidity of the water pipes, reinforced with tees, we were able to abandon the rear support posts necessary in case of installation of traditional structures.

If you decide to optimize the living space in a private house, where there is a staircase leading to the second floor, the space under it can be used to arrange a shelving unit, as shown in the photo.

Development of a drawing of a wooden shelving: general requirements

Development of a drawing is an obligatory stage and the key to arranging a convenient and practical rack. To make a drawing in accordance with all the requirements, first of all, you need to accurately measure the place where the rack will subsequently be located. If you plan to use the structure for storing work tools or cans of winter preparations, experts recommend giving preference simple forms. In this case, it will be enough to determine the height of the product, which depends on the height of the room and the individual preferences of the owner. As for installing a wooden rack in the garage with your own hands, it is recommended to do it the full height of the wall. The width of the shelves of the rack depends on what items will be stored on them - to arrange cans or books, shelves 25-40 cm wide are suitable, shelves for storing working tools are mounted taking into account their dimensions. The length of the shelves is another parameter that depends on the purpose of the rack. If shelves 1.5 meters long are suitable for storing toys, figurines and other small items, then for heavy books you need to choose shelves whose length does not exceed 90 cm, which will prevent them from sagging.

To summarize, let's take a quick look general recommendations that must be observed during the development of the drawing:

- The width of the rack is calculated taking into account the free space - its width corresponds to the width of the free space, however, for ease of installation, the resulting figure is reduced by 5-10 cm;

- The width of the shelves should be no more than 1.5 m, which will prevent their deformation;

- As for the depth of the shelves, the most optimal value here is 50 cm. If, despite the recommendations of experts, you increase this figure, be prepared for the fact that difficulties will arise when getting items from distant shelves;

- Most optimal height shelves - 30-60 cm, while the bottom shelf may be a little deeper, which is especially important if you plan to store large items on the rack;

- In the process of developing a drawing, it is necessary to make an approximate estimate of the dimensions of the items that will be placed on the shelves of the rack, and taking into account the 10-15 cm gaps necessary for the free placement and removal of items from the rack, calculate the length of its shelves;

- Don’t forget about the rule of rational load distribution. It is preferable to place the heaviest and most bulky items on the lower shelves of the rack, on the middle shelves - objects of medium weight and size, on the top - voluminous but light items (boxes, clothes).

Important! If you are planning to arrange a structure for storing things in a small room, the most suitable option a corner wooden rack will be for you. Its installation involves joining two racks at an angle of 45 degrees, which must be reflected in the drawing.

Materials and tools for making a rack

Before you start making a rack, prepare the necessary materials and tools:

According to experts, in order to make a high-quality rack, it is advisable to use boards made of natural wood. The most preferable, in this case, would be pine, oak or mahogany. It is not recommended to use boards made from wood shavings, since they are an impractical material with a short service life. When choosing wood for making shelving, it is important to ensure that its moisture content does not exceed 12%. Before making the rack, the material used must be prepared - treated with antiseptic solutions and special impregnations, after which the boards must lie in the room where installation will take place for several days.

In addition to wooden boards, to make a rack you will need the following set of materials and tools:

- shelf holders;

- metal corners;

- wooden blocks, with the help of which the transverse fixation of the shelves will be carried out;

- furniture legs on wheels;

- plywood;

- self-tapping screws;

- wood varnish and brush;

- wood glue;

- electric jigsaw and grinder;

- drill;

- hammer;

- tape measure and pencil, which will be needed for marking.

How to make a wooden rack?

- The first stage of installation activities is the selection of the lower base. To make it, select a thick board (its thickness is selected so that a 3 cm long self-tapping screw fits freely into it). As for the remaining design parameters, the length and width of the board are equal to the maximum length and width of the rack, which you select yourself. At the bottom of the base, in increments of one meter, experts recommend nailing transverse bars, the length of which is equal to their width. This will give the structure additional strength.

- The next step is to work on the side walls of the rack. To reduce the cost of construction, thick plywood can be used instead of boards, marking it so that its width is equal to the width of the base. The height of the plywood is chosen arbitrarily. Cutting out side walls required sizes, make marks for the shelves on their insides. At the same time, remember that most often the height of the shelves is 21 and 42 cm. These two values can be alternated, which will allow you to equip the rack with spacious and, at the same time, neat shelves.

- Next, cut out the wooden shelves. Their length must correspond to the inside of the rack so that they fit tightly and, at the same time, freely into the rack. The width of the shelves corresponds to the depth of the rack. As for the thickness of the shelves, it should be at least 2.5 cm, but experts recommend fixing them with transverse bars, which will give them additional strength. To nail the bars, you can use regular small nails.

- Once you have cut out the shelves, you can begin making the back wall. To simplify the task, experts suggest abandoning the installation of the rear wall, but this is only if you are completely satisfied with the texture and color of the wall to which the rack is adjacent. If mounting the rear wall is necessary, it is cut out of ordinary plywood in accordance with the dimensions of the rack.

Assembling the rack: step-by-step instructions

- After all the parts have been prepared, it is necessary to proceed to the next important stage of manufacturing a wooden rack - assembling the structure. At this stage it is important to use different kinds fastenings: from wood glue to screws and nails.

- At the first stage, take the lowest shelf, which will be used as a base, and attach the back wall of the rack to it using self-tapping screws. If the design of your wooden shelving for a balcony or other room does not include a back wall, immediately begin working with the side walls. Previously, you have already made markings for attaching the shelves, which will facilitate the subsequent stages of assembling the rack.

- At each of the marks, parallel to each other, it is necessary to attach special metal or plastic (depending on the expected load on the shelves of the rack) holders, on which the shelves will subsequently be placed. Then, using self-tapping screws, the side walls are mounted to the lower base, while maintaining the evenness of all corners. To increase the reliability of the structure, it is recommended to use metal corners as additional fixing elements.

- Above we described one of the common options for mounting shelves. It is not the only one and in terms of its reliability it is inferior to the method that will be discussed below. Another, more thorough method of attaching shelving shelves does not involve installing holders, since the shelves are attached directly to the side walls. First of all, using self-tapping screws, the side walls are mounted to the base. Then, in order to effectively complete the task, you will need the help of a partner who will place the shelves inside the rack in accordance with the previously made markings, while you will attach them to the sides from the outside using self-tapping screws. To increase the reliability of fastening, it is advisable to additionally fix the shelves from under the bottom with metal corners. Giving preference this method fastening shelves, it is important to remember that, along with greater reliability, it is considered more complex and requires ideal measurements of the length of the shelves. During the installation process, it is important to avoid even minimal distortions, as they can completely ruin the structure of the rack. To prevent this, you must use a building level from the very beginning.

Having prepared the main part of the structure, proceed to attach the cover, which will give the future rack a finished look and prevent dust from getting on it. top shelf. Self-tapping screws are also used in the fastening process.

Another way to increase the reliability of the shelving structure involves coating the holes after drilling with wood glue, which will provide additional strength. It is recommended to use furniture legs on wheels as the legs of the future rack, which will make moving the structure more convenient and, at the same time, will prevent distortions of the rack when exposed to high loads.

If you used to make a rack chipboards or MDF, add finished design You can achieve a more aesthetic and finished appearance by gluing melamine film to all ends of the parts, which can be achieved using a regular iron. The edge is laid on the end, previously treated with fine-grained sandpaper, and smoothed with a hot iron. If there are any excess edges remaining, they are removed using a utility knife.

To add originality to the rack, some shelves can be closed with doors or even turned into an entire wardrobe. Additional design of the rack, which will make it decorative, can be done by painting it with stain or varnish, using decoupage or craquelure. The latter depends only on your imagination and individual preferences.

DIY wooden rack video

In a new review, the author has collected examples of racks and shelves that you can make with your own hands. They must, of course, be used for their intended purpose. Having looked at the photographs collected here, you can easily make sure that there is nothing fundamentally complicated in the proposed option.

1. Circle shaped

An original round shelf, the edging of which is made of thin fiberboard, and the shelves themselves are made of ordinary boards painted in White color. Of course, this design is not suitable for storing the entire home library, but it can accommodate several educational books, a small indoor plant and a couple of framed photographs.

2. Wall shelf

A charming hanging shelf that can be made from several unwanted books or notepads of the same size. Such a shelf is not only suitable for storing cosmetic accessories and small decorative items, but in itself will become a wonderful decoration for any wall.

3. Arrow

Stylish bookshelf in the form of an illuminated arrow, made from the remains of metal water pipes, it will fit perfectly into the interior of a teenage boy’s room or a bachelor’s apartment.

4. Practical and unusual

An original and practical shelf that can be made from a small tray from an old cart and several wooden blocks. This shelf is reliable and spacious and is suitable for storing a wide variety of things.

5. Charming shelving

A stylish and original shelving unit made from a slightly modified door painted white. Filled with your favorite books, candles, family photos and small decorative elements, such a shelving unit will be a real highlight of any space.

6. Narrow slats

Old skis that have been collecting dust in the closet for many years can be used to create unusual shelves. Such shelves will fit perfectly into the interior of a nursery and are suitable for storing toys and books.

7. Stylish copper

Massive shelves made of wood covered with stylish film copper color, are perfect for placing house plants.

8. Old pallet

Old wooden pallet Simply turn it into an original shelf for storing magazines and family photos.

9. Industrial style

A stylish storage system in the current industrial style, which can be made from wood or MDF boards painted in grey colour and interconnected by a structure of metal water pipes.

10. Bright honeycomb

Original shelves made from bright hexagonal gift boxes attached to mirrors of the same shape. Of course, this design is not suitable for storing large, heavy objects, but it is suitable for storing little things that are dear to the heart and decorative items, and will also become a unique wall decoration.

11. Stylish transformation

Drawers an old table, ready to be thrown away, can be used to create original shelves. Carefully painted and modified at your discretion, the drawers can be attached to the wall, both vertically and horizontally, and used to store a wide variety of things.

12. Rough design

Rough shelves made of untreated wood, exposed with varnish or paint, will fit perfectly into the interior of a room decorated in a rustic or country style.

13. Abundance of cells

A huge wall-length shelving unit made from many wooden boxes, painted in bright colors, can become a stylish and budget-friendly alternative to a massive store-bought wardrobe.

14. Wicker basket

MDF shelves.

Compact MDF shelves with fruit slices painted underneath them will become a bright and functional decoration of the kitchen wall.

17. Rustic style

A sturdy piece of bark or raw wood can be turned into a fantastic hanging shelf that provides a creative alternative to a standard bedside table.

The time comes when there is critically not enough space for tools and various available materials in the workshop or the same garage. The first thing that comes to every man’s mind is to make an audit and throw it in the trash unnecessary trash. Well, that was not the case, because when it comes to deciding what to keep and what to throw out, it is not common sense that takes over, but the thriftiness of the Russian peasant, which is ingrained at the genetic level into his nature. After thinking a little, most men stop at the idea of how to make a shelving unit with their own hands.

The time comes when there is critically not enough space for tools and various available materials in the workshop or the same garage. A shelving unit is the ideal way out of this situation, which will make it possible to free up some space in the room.

A shelving unit is the ideal way out of this situation, which will help save everything acquired through back-breaking labor and make it possible to free up some space in the room.

- Prefabricated is the simplest option, which allows you to assemble its structure yourself in a matter of hours. Nowadays, there are many prefabricated racks of different sizes on the market, from various manufacturers. The main advantages are that they are made of specially treated materials (galvanized steel, wood), which increases their service life. In addition, the shelves supplied can be mounted on different heights followed by rearrangement.

- A rack made of a metal corner (profile) with wooden (metal) shelves. This one has increased strength, since the frame is made of durable metal and is able to withstand a lot of weight. Due to the fact that the rack is made by hand, its dimensions can be adjusted to the actual dimensions of the room, mounted along one of the walls, right up to the ceiling.

- Wood. Such a rack is made according to the same design diagram, like metal. Except that for the main racks, wooden blocks are used, rather than a metal profile. As a rule, production is resorted to when the budget is limited. Because wooden blocks are much cheaper metal profile. The only thing you need to pay attention to is that the load capacity of such a rack is much less, unlike its metal counterpart. And the service life is inferior to the second type.

Making a metal analogue

Before starting work, it is necessary to prepare protective equipment: your hands should be wearing gloves, and your eyes should be protected with special glasses. If the safety regulations are met, we proceed to production.

In most cases, when considering the options, the choice falls on a shelving unit based on a metal frame with wooden shelves.

Depending on the room and location, it is not difficult to calculate required amount materials for its manufacture. When preparing materials, the following nuances must be taken into account:

- The total length should not be equal to the length of the wall along which it will stand, but should be 10-15 cm less. It is recommended to adhere to this condition, otherwise installation in the chosen location will be difficult.

- The height is limited by the ceiling and the height of the profile, if it is not specially prepared, but is already available.

- Before preparing material for shelves, it is necessary to take into account the maximum weight of the load that is supposed to be placed on them. The size of the shelves must be chosen taking into account the fact that maximum dimensions should not exceed 1 m.

- When making a rack, you need to maintain its versatility, taking into account the fact that it will store not only hand tool. Based on this, the depth of the shelves should be in the range of 40-60 cm.

- The height of the shelves should correspond to the height of the items that are planned to be stored on the rack. Typically, the height of the shelves corresponds to 30-50 cm. The bottom shelf, as a rule, is twice as high as the next ones.

Materials

- For the manufacture of frame racks, a 30x50 mm corner is mainly used. At the same time, its alternative replacement is a 20x50 mm profiled pipe.

- In order to securely fasten the shelves, a frame is made for them from a 15x25 mm corner.

- Since the chosen material for the shelves is wood, you will need a board 15x25 mm thick. Before installing the shelves, the board will need to be further processed, painted or oiled.

The total footage of materials is calculated by simply summing the lengths of the component parts in accordance with the drawing. May be needed Consumables, such as 10mm threaded bolts.

Required tools:

- Welding machine (in the absence of a drill).

- Saw on wood.

- Bulgarian.

- Electrodes - 1 kg.

- Set of drills.

- Roulette.

- Level.

- Enamel PF-115 - 0.5 kg.

- Primer - 0.5 kg.

- Cutting wheels - 2 pcs.

- Chalk (scriber).

- Self-tapping screws - 1 pack.

Work order

Using a tape measure we mark required length on a pre-prepared profile. Next, you need to use a grinder to cut all the necessary components. Profile trimming can be ordered directly where the profile is purchased, but in this case the cost of the rack itself increases, since this service is usually paid.

Using welding, it is necessary, in accordance with the drawing, to make a frame, securely welding the joints at the joints. This is the most critical moment, since the main structure of the rack with vertical posts must be strong and withstand a fairly large weight. When making a frame, it is necessary to constantly monitor the level of the entire structure so that it does not turn out uneven.

The next stage is preparing the frame for future shelves. It is also carried out by welding corners with a lower flange height.

Next, you need to accurately measure and mark with chalk (scriber) the places where the shelves will be attached to vertical posts. In these places, the frame for the shelves is welded to the racks, and their horizontalness is simultaneously controlled. If the shelves turn out to be non-horizontal, the tool will simply roll off them.

For greater versatility, the frame can be attached to the racks using bolts; to do this, you must first mark the drilling locations on the racks and frame so that during installation they coincide and the bolt fits into them.

Also, for greater versatility, the floor frame can be attached to the racks using bolts; to do this, you must first mark the drilling locations on the racks and the frame so that during installation they coincide and the bolt fits into them. Although this method, unlike welding, has an advantage, namely, the height of the shelves can be adjusted if, of course, you drill additional holes, but at the same time it requires more effort.

Next, you can begin making the shelves. Shelves can be made not only from boards, but also from fiberboard. Before cutting the prepared material for this, it is necessary to take into account that in order to give greater strength, it is necessary to cut the boards (fiberboard) not along, but across the rack. This way they will sag less and, accordingly, support more weight. After the blanks for the shelves are cut, you need to try them on, and if everything fits well, they do not fit in the frame, start processing them. In most cases, painting them will be sufficient.

Once the shelves are dry, you need to screw them to the frame. For this, as a rule, metal screws are used.

To make the shelving more stable, it can be attached using brackets or spacers in the wall.

Based on the above, the answer to the question has been received: how to make a rack yourself? Having analyzed everything, it is easy to see that making a rack does not require significant costs and effort.

In small apartments, the problem of lack of space to store certain items often arises. If in a large living space it is possible to arrange a storage room or closet, then a small apartment excludes this possibility. The simplest solution would be to install a wooden shelving unit.

But it will become useful not only in the apartment, but also on the balcony, where a lot of things are often stored, and in the garage, where car accessories and tools must be placed in their places so as not to waste time constantly searching for them. It is very interesting to fit in a shelving structure for zoning space, for example, in a studio apartment.

Despite the fact that even a beginner can make a shelving unit, there are still some nuances that, when observed, will help create a high-quality piece of furniture at a minimum cost.

Types of wooden shelving

A wooden rack is a structure consisting of several shelves attached to support board. Their number depends only on the desires and capabilities of the owner. Prefabricated wooden shelving will fit perfectly into any interior and help you store various items, for example, books, dishes, souvenirs, etc.

The functionality of the rooms where this piece of furniture can be placed is very diverse.

It is very convenient to install shelving in the nursery, where, thanks to the availability of free space and open shelves, the child will be able to place all his toys and get them out without the participation of adults.

In the office, the structure will serve not only as a place for storing documents, but will also become a wonderful decorative element workplace.

For a kitchen, a shelving unit is a must. Dishes can be stored there, as well as neatly arranged containers with bulk products.

On the balcony, a wooden rack is used to place seedlings or indoor plants in warm time of the year. Everyone knows that plants generally need a little heating. Nowadays you can purchase special pieces of furniture with heated shelves, but self-made ones can also perform this function if each shelf is covered with foam plastic. This material accumulates heat and transfers it to plants.

Depending on the design, a suitable option can also be selected:

Original shelving

Such pieces of furniture should be given special attention, since they are created in accordance with individual project which is suitable for certain interior. Ordinary rough DIY wooden structures are only suitable for balconies or garages, but to decorate your living space it is better to use something more original. For example, the rack with bottles in the form of racks shown in the photo will fit perfectly into the living room or kitchen. Despite its external instability, books and even collectible bottles of wine can be stored on it.

Interesting in the interior, especially nautical style Look like rope structures of wooden shelving for the home, which are attached to the wall using massive hooks. Of course, it’s unlikely that you’ll be able to store something heavy on such racks, but small souvenirs or photo frames are fine. This design is very simple to make; all you need is a thick rope and a few scraps of wood. Shelves can also be made from leftover laminate flooring.

For interior in modern style designs using metal are suitable. One of these is the design of a rack with many shelves in a chaotic order, which are interconnected by metal tubes. Thanks to metal elements create rigidity, you can dispense with the back wall.

If you plan to create a shelving unit in a private house, then you can arrange it in the space under the stairs, as shown in the photo.

Making your own shelving

Making a wooden rack with your own hands is quite simple if you study all the nuances of the work in advance and thoroughly prepare for it.

Project development

Creating a project for a future structure is very important stage, which must under no circumstances be missed. First of all, measurements are taken of the place where it is planned to place the rack. If the rack will not be intended for decorative purposes, but will be used only in accordance with the storage function, then it makes sense to carry it out in a simple form. To do this, measure the height of the wall near which the furniture will be located and calculate the indicator that suits the owner.

Important! In a garage, the shelving is best made to cover the entire height of the wall.

The parameters of the shelves for the structure, both in length and width, deserve special attention. Long shelves of 1.5 meters are ideal for storing light items, for example, souvenirs and toys, but jars with blanks and books require shorter ones - about 90 cm, so that there is no sagging. As for the width, shelves with a width of 25 - 40 cm will be suitable for storing books and cans, as well as growing seedlings, and for tools or larger items, those that will correspond to their size are arranged.

In general, the dimensions of the shelves completely depend on what will be placed on the rack, so first you should estimate the approximate location of the items and add 10 - 15 cm to the calculated figures so that you can easily put and remove the item.

Necessary tools

Professionals advise for self-made For shelving structures, use only strong and solid wood. It could be pine, mahogany or oak. Materials made from pressed sawdust are not suitable for installation, as they are quite short-lived.

Important! The moisture content of wood for shelving should not exceed 12%.

The boards are impregnated with antiseptic impregnations in advance and left for several days so that the solution is absorbed.

In addition to boards, you will also need to make a rack:

- Metal corners

- Shelf holders

- Bars for stuffing them into the bottom of the shelf

- Furniture legs or wheels

- Self-tapping screws

- Wood glue

- Varnish or other paint material, which will be used for finishing

- Jigsaw and sander

- Hammer

- Drill with matching drill bit set

- Tape measure, level and pencil

Algorithm for making a wooden rack

To begin with, prepare all the parts necessary to assemble the rack.

Prefabricated wooden racks are manufactured starting from the bottom. For the bottom shelf, the thickest board should be selected, into which a 3 cm screw can easily fit. The shelf parameters are selected depending on the project, which describes all the dimensions of the future structure. Also, if the length of the shelf is large, then it is better to mount transverse bars in its lower part to add rigidity.

The next step is the installation of the side walls. For them, not solid wood, but thick plywood can be used. They cut it out required sizes side walls, on their inside the location of future shelves is marked. It is worth remembering that the most commonly used height of the shelves in the design is 42 and 21 cm. These indicators can be alternated to get a neat and functional rack.

Cutting shelves from wood. Their size must correspond to the rack and be such that the owner can install and remove the shelf without restrictions.

Important! The thickness of the shelves should be at least 2.5 cm, but to give strength they can be equipped with transverse bars at the bottom.

The next step is optional and is performed only at the discretion of the master. If the wall against which the shelving structure will stand completely suits the owner, then the back wall need not be mounted to it. If it is customary to mount the back wall, then it is cut to the size of the plywood rack and nailed to it with small nails.

All the parts are prepared, now you can start assembling the entire structure:

- The back wall is screwed to the bottom shelf, which is the base. If it is not there, then you can immediately attach the side ones.

- But before installing the side walls, you need to install holders, which can be metal or plastic, in the places marked for shelves.

- Afterwards, the side walls are attached to the base with self-tapping screws. If necessary, a metal corner can be used.

- Also, the shelves may not be supported special elements, and attached directly to the side walls. To do this, the shelf is held inside the rack by an assistant, and the second master screws in the screws with outside. To increase strength, shelves can be supported by metal corners.

Advice! At all stages of rack assembly, it is mandatory to use building level, which will eliminate any distortions.

To create a high-quality shelving design, there are several tips that are optional, but very desirable:

- The main structure of the rack can end with a top cover. This is very convenient due to the fact that the rack will become stronger, and dust will not fall on the top shelf.

- For additional strength, the holes are coated with wood glue after drilling.

- If you use wheels instead of regular legs, the rack can be moved. Also, installing these elements will help prevent the structure from distorting under heavy loads.

- If chipboard or MDF were used to make the rack, then their ends are treated with melamine film, which is easily glued with an iron. Such a strip is placed on the end treated with sandpaper and processed with a hot iron. Thus, the end will close and acquire an aesthetic appearance.

- For greater decorativeness, the rack can be supplemented with doors or other elements that will only decorate it.

Conclusion

A shelving unit for your apartment will be a very functional addition that can be used to display memorabilia or other items. It is possible to make this piece of furniture yourself, which will allow you to save money and get exactly the design that is needed. This is not difficult to do, just read this article, which contains detailed instructions on installation.