Schematic diagram of a hair dryer. How to fix a hair dryer if it's broken? How to assemble a hair dryer with your own hands The hair dryer does not work at full power

Page 1 of 2

This electrical appliance - a hair dryer - is very popular and often indispensable in everyday life. Due to high consumer demand, the designs of most hair dryers have become very similar, and the quality of workmanship and price have dropped. Today, buying a truly durable hair dryer is very difficult. Hairdryer repair practice various brands indicates that the breakdowns that occur are of the same type and, as a rule, are not fatal, but can be easily fixed without serious expenditure of money.

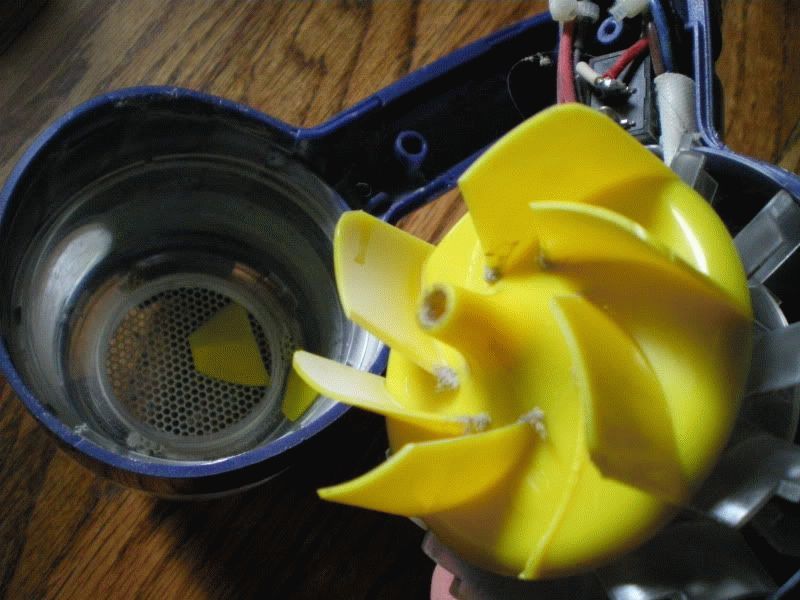

Any electric hair dryer in its design it contains two main, large elements: a fan and a heater. The fan drives air through the heater ( a heating element), sucking it in behind the hairdryer and throwing it out in front, heated.

Hair dryer device.

1 - propeller; 2 - electric motor; 3 - heater; 4 - thermal protection; 5 - mode switch; 6 - power cable.

In household hair dryers, the fan is built on the basis of low-voltage (12-18 V) DC commutator motors. Such an engine cannot be powered directly from a 220 V network. alternating current. For achievement necessary fall voltage, a separate coil (let’s call it a step-down coil) is used inside the heating element. To rectify the voltage, a full-wave rectifier (diode bridge) mounted wall-mounted on the motor contacts. A plastic propeller consisting of three or more blades is mounted on the metal shaft of the engine.

The heating element of the hair dryer is a frame made of fireproof material with several windings of nichrome wire (spiral). Depending on the number of operating modes of the hair dryer, there may be two or three windings, one of which is step-down.

Heating element with two windings.

The hot coils of the heating element must be constantly blown with cold air, especially when operating at maximum power. If for any reason the air supply becomes insufficient or stops altogether (for example, the engine fails), then, for reasons fire safety and to avoid burning out the heating element, the hair dryer should turn off automatically. This emergency shutdown occurs due to the presence in the hair dryer of two heat-sensitive elements at once - two “lines of protection” inside the heater.

The first “frontier” is the thermostat. It consists of a pair of closed contacts attached to. Being close to the outlet of heated air, the contacts are intensively blown by it. When the exhaust air reaches a critical temperature, the contacts move away from each other, and the power supply circuit of the hair dryer opens. After a few minutes, when the bimetallic plate has cooled, the contacts will close again and the hair dryer will turn on.

Thermostats based on bimetallic plates.

In the event that the above protection for any reason right time did not work, then a few seconds later the “second line” of protection is activated - the thermal fuse. This fuse is disposable and, after tripping, needs to be replaced.

Thermal fuse.

Rowenta CV 4030 hair dryer device.

To see internal organization household hair dryer, let's look at its typical representative - Rowenta CV 4030. This model is equipped with a fan based on a low-voltage motor, the heating element consists of one reduction coil and two heating coils. The hair dryer has three operating modes; in the first mode the fan speed is lower than in the other two. The schematic diagram of this hair dryer is presented below.

In the first position of the switch SW1 mains power passing through the plug XP1, filter C1R1, protective elements F1, F2, diode VD5(necessary to cut off one half-wave of alternating voltage) is supplied to the reducing spiral H1, the electric motor is powered through it M1. Diodes VD1-VD4 necessary for straightening the lowered spiral H1 alternating voltage. Inductors L1, L2 and capacitors C2, C3 serve to reduce interference that occurs during the operation of the brush motor. Via diode VD5 power is also supplied to the heating coil H2.

When you move the switch SW2 to position “2”, diode VD5 short-circuits and “goes out of the game.” The engine starts to operate at maximum speed, the spiral H2 heats up more. Third position of the switch slider SW2 corresponds to the maximum power consumption mode when parallel to the spiral H2 spiral is connected H3. In this position, the temperature of the exhaust air is highest. The “cool” button is included in the gap of both heating coils; when pressed, only the electric motor through the coil remains switched on H1, helix H2 And H3 are de-energized.

The process of opening the Rowenta cv4030 hair dryer.

Hairdryer in semi-assembled form.

When your fiancée's hair dryer stops working, it can turn into a tragedy...

Of course, you can please your beloved by purchasing a new one, but believe me, if you undertake to repair the old one and succeed, you will not only save your household budget, but also increase your status as an owner, husband and jack of all trades!

Of course, for many, repairing such devices will not cause any particular difficulties due to own experience and knowledge, but not everyone is such a master fixer!)

Now, using a live example, let's look at some typical faults this type of technology, and those who have never encountered such work will see that there is nothing overly complicated about it. Of course, there will be differences in different devices, but the principle is the same.

The first thing you should pay attention to is the power cord; often the wire breaks either at the base of the power plug or at the hair dryer handle itself. Moreover, a broken wire may visually appear to be in good condition because it is covered with rather thick insulation on top.

Such a malfunction is often detected by the fact that by bending the wire in the above places, the device can work. But make no mistake, you cannot operate electrical appliances with such a wire; the wire must be replaced.

To do this, you will have to disassemble the hair dryer, but this will also be needed to troubleshoot other problems. Let's get started.

How to disassemble a hair dryer

As a rule, all modern hair dryers, as well as other household devices of this kind, do not always have fastening bolts that are accessible and visible; they are often hidden behind various plugs or plastic panels which need to be unfastened. The patient for this article, an old Rowenta hair dryer, is no different in this sense.

Unclip and remove the plastic panel on the hair dryer handle

Fine flat screwdriver or better yet, use a short mounting knife to press the latches and remove the cover. Next you need to disassemble the mechanism for switching the speed mode. To do this, remove the switch wheel axis and remove the bar.

Then we remove another cover and only now can we unscrew the fastening bolts.

By the way, for this you often need a cunning screwdriver, such as a triangle, an asterisk, or a flat one with a slot; in my case, this is a homemade product made a long time ago from an old flat screwdriver, but now you can buy these.

Now that the two screws are unscrewed, complete disassembly It is necessary to remove another plastic part of the case.

Well, we got to the insides.

Well, we got to the insides. Now, you can replace the wire and perform any other repairs.

What was the cause of the malfunction

In my case, the heater shutdown button was broken. Do you know what this button is for? Many, as it turned out, are not aware. The fact is that if you turn off the hair dryer immediately, without using this button, there is a risk of damaging the device. This can happen because the fan immediately stops after turning off, and the coil has not yet cooled down, the heat has nowhere to go, the hair dryer overheats, and you can even melt the body. And this button allows you to turn off and blow through the coil while the fan is running, giving it the opportunity to cool down somewhat.

So this very button failed, the fastening of one of the contacts broke, so the hair dryer only blew cold air. To repair it, I had to slightly widen the hole of the torn contact and, putting it in place, melt it with plastic to fix it. Of course, before this it would be correct to clean the burnt contacts.

In general, after these simple steps (it takes much longer to describe than to do), the hair dryer worked properly.

What other problems can you fix yourself?

Check the integrity of the power cord, plug, quality of connections, soldering. The button itself can also, if necessary, be disassembled for cleaning, but this must be done carefully so that the contacts and spring do not jump out (used in some buttons). If the button is seriously malfunctioning, it will already have to be replaced; this may not be possible due to the fact that it just can't be found.

The fan motor and the spiral itself are also poorly repairable - if they malfunction, either professional intervention is required, or...... Long live the store!

Another one possible malfunction repairable - thermal fuse.

This is a self-resetting fuse that turns off the heater coil when overheated, and after cooling it returns to its original, closed position. But it happens that its contacts burn out over time and it stops working normally. You need to restore good contact, carefully use something thin (a nail file works great while your wife can’t see) and shuffle between the contacts, but do not loosen them more than the thickness of the file. Otherwise, you will then have to bend the contact plates to compress them well.

Sometimes tucking is simply necessary. But be careful, it’s not that simple, remember that everything is attached to a fragile mica base and putting in effort can only make everything worse.

Remember that with any repair, care and accuracy are important! This is one of the keys to success!

Recently, a hair dryer was brought to me for repair, not one of the most old-fashioned, but times are different now, who repairs a hair dryer for $10, and sometimes it’s easier to buy a new one, taking into account that the entire market is literally filled with cheap Chinese hair dryers. So, let’s take this opportunity to look at the design and operation of hair dryers.

The hairdryer operates on 220 V, 50 Hz. Any hair dryer has two main parts - a heating element and an electric motor.

A nichrome spiral is usually used as a heating element; it provides warm air. Hair dryers mainly use DC electric motors with a power of up to 50 watts, there are exceptions.

Passing through the spiral, the current loses its initial strength, since the spiral has a certain resistance; it is this current that is rectified by the diode bridge and supplied to the electric motor.

Electric motors in hair dryers are designed for voltages of 12, 24 and 36 Volts; only very rare models use electric motors with a power supply of 220 Volts, in which case the voltage from the network is directly supplied to the electric motor. A propeller (propeller) is attached to the engine rotor, which removes heat from the spiral; it is thanks to this that a fairly strong directed flow of warm air is obtained at the output. The power of the hair dryer depends on the thickness of the coil used and the power of the installed electric motor.

The brought hair dryer was disassembled, it turned out that the problem was a broken track on the circuit board with switches. After filling it with solder, the device worked fine.

But most often, the main reasons for malfunction are a broken spiral, a non-working motor, switch contacts melted from heat, a broken power cord or plug.

Elements in the diagram: 1 — diffuser nozzle, 2 — body, 3 — air duct, 4 — handle, 5 — cord anti-twist guard, 6 — mode button “ Cold air", 7 - air flow temperature switch, 8 - air flow speed switch, 9 - "Turbo" mode button - maximum air flow, 10 - loop for hanging a hair dryer.

The electric motor is supplied with DC voltage obtained through a diode bridge consisting of four diodes (or simply from one diode).

Let's highlight two elements of the circuit that are consumers (loads), these are the spiral and the diode bridge (we do not count the motor, because it is the load of the bridge). In the circuit, the elements are arranged in series (one after the other), which means that the voltage drop across each of them will depend on its own resistance and their sum will be equal to the network voltage in the third position of the switch.

Most hair dryers entry level They have a simple electrical circuit; in such hair dryers there is only one switch that turns on the fan and heating element. Heaters can be made in various modifications, but in all hair dryers they are made of nichrome twisted into a spring.

However, almost all simple modern hair dryers have 2-3 stages of power and air flow adjustment.

More advanced hair dryers have smooth controls for blowing speed and temperature of the blown air.

The recommended maximum operating time is 5 minutes. Upon completion of work, turn the temperature regulator to minimum, leave it on cold air for half a minute, and only then turn off the hair dryer. Try not to take it wet hands, otherwise moisture may get into the internal elements circuit, which can lead to a short circuit.

A hair dryer consists of a motor, a fan, heating elements, and an electrical circuit that makes the elements work in harmony. Depending on the number of modes, the manufacturer, the element base, appearance, and composition of the switches are different. But there won’t be anything more complex than a semiconductor thyristor inside. Therefore, we will carry out home repairs of hair dryers with our own hands.

The body is held on by screws. The heads are often non-standard. This is a plus sign, an asterisk, a pitchfork. Therefore, first of all, before fixing a hair dryer, let’s take care of a tool that can cope with such a task. Fortunately, a set of bits costs 600 rubles today.

Sometimes the case doors are additionally secured together with special latches. This is a separate problem: experienced craftsmen They often break plastic, despairing of coping with civilized methods. There are no tricks, they come up with hidden screws hidden under stickers, plastic inserts, and removable regulator caps. The fastener is fictitious. Useful features none.

The hair dryer motor is powered by direct current 12, 24, 36 V. A diode bridge is used to rectify the mains voltage; in cheap models, a single diode is used. Filtering of power harmonics is carried out by a capacitor connected in parallel with the motor windings or included in a more complex filter. Due to their enormous mass, inductors are rarely used in hair dryers. Therefore, knowledge of the principles of smoothing ripples with RC circuits is enough to cope with the construction of a circuit diagram of a hair dryer being repaired. Sometimes the filter element uses one spiral (inductance).

The hair dryer switch simultaneously closes the circuit through which the coils will be powered and starts the motor. Further intervention schemes are determined by complexity:

- only the rotation speed or only the temperature is regulated;

- the ability to individually select heating and air flow intensity.

In most hair dryer models, there is parallel protection against turning on the heaters when the motor is idle. Protects the spiral.

An optional thermostat in the form of a special resistance or other sensitive element. Let us describe the breakdowns that occur in the faithful assistants of the fair half of humanity.

Typical Inspection Procedure

If the device has no signs of life and is unstable, the inspection begins with the power circuit. Below is a schematic description of the repair of Rowenta hair dryers.

Attention! The described types of work require skills in handling electrical appliances. The authors disclaim responsibility for damage to health and property that occurs when attempting to follow the given recommendations for repairing hair dryers.

Cord

Inspection of the power wire begins with the socket. Some of the faults lie there: there is no voltage - the hair dryer does not work. If there is voltage in the outlet, inspection of the cord begins at the point where it enters the housing, moving towards the plug. Work is performed on a de-energized device. A visual search is carried out for kinks and irregular formations - burns, insulation damage, fractures.

Then the hair dryer body is disassembled. Inside you have a chance to see the electrical resistance options:

- A pair of detachable contacts.

- Soldering.

- The wiring is sealed in plastic caps.

Permanent connection

The last element of the list characterizes a non-separable connection, therefore, the case for testing is extremely complex. Skillful hands, or rather, smart heads, Ukrainian brothers in wisdom are advised to use an ordinary needle to repair a hair dryer. Those who immediately grasp the train of thought will skip the next paragraph; start testing directly.

Repairing a hair dryer with your own hands begins with checking the wiring. A Chinese tester, a light bulb, and an indicator will do. A needle is attached to one terminal, which is then inserted into the power core in the area of the cap through the insulation to the copper. The second terminal feels the legs of the plug. The call goes through for both wires. When repairing a hair dryer, you shouldn’t make more than 1 puncture per wire (some will also try to look for the break point), since the nature of the operation involves moisture getting in from wet hair.

Contact pad

Even a child can ring the wire, having visually distinguishable junction points in front of his eyes. If damage is found, it is recommended to buy a new cord equipped with a non-detachable plug. The possibility of moisture ingress limits the choice of insulation of conductive parts used to repair the hair dryer.

Cases are common: the first glance reveals the location of damage to the cord entry into the housing. Sludge, carbon deposits, black insulation indicate the location of the fault.

At the junction with the body of the hair dryer there is a vulnerable wiring point. The hostess takes the delicate device by the cord, shakes it from side to side, and winds the cable around the handle. A core with a crack sparks, the insulation heats up, burns, and the copper melts. This is the mechanism of damage to copper conductors.

Switch and switch

When updating, it is useful to short-circuit the switch and check: the hair dryer will change its behavior radically in response to a simple step. There are three-position switches, each short-circuited position is checked separately. Remember, sketch out the original wire layout before you begin repairing the hair dryer.

Checking the speed and temperature switches uses a similar circuit.

Inspect the defective element identified during the restoration of the hair dryer. The deposits are cleaned off with a file, sandpaper, or eraser. Contacts are wiped with alcohol. Faulty components are replaced with equivalents. Radical method- short-circuit the power button while searching for suitable components.

Fan

Relatively often, the air duct of a hair dryer becomes clogged. It is necessary to remove the filter, if any, and clean it thoroughly. Use a soft brush to remove dust from crevices.

No blade rotation or low rpm is often observed when hair is wrapped around the motor axle. The propeller must be carefully removed from the shaft, avoiding in every possible way extra effort and distortions. After this, foreign objects are removed.

Spirals

A hair dryer usually has several heating elements. Visually they should all look uniform. Make sure of this when fixing the hair dryer by opening the case. Detected breaks are eliminated by twisting the ends, soldering and tinning. You can also get thin copper tubes and crimp the ends of the broken spiral inward.

During repairs, defects in heating elements can be observed visually. A careful inspection will tell you how to fix the hair dryer. It is effective to replace spirals with similar purchased or homemade products made from nichrome wire.

Engine

The electric motor of a hair dryer can be powered by both direct current and alternating current. If the diode bridge burns out, the windings are damaged, normal functioning is violated. A terrible crackling sound and sparks when turned on indicate a motor malfunction.

The motor windings are desoldered when repairing a hair dryer from the electrical circuit. For each wire, find the pair that rings. The terminals are connected in threes; none should hang in the air. Replacing the winding when repairing a hair dryer is carried out only in a workshop. However, folk craftsmen work no worse than machines. Those who wish will try it.

If the windings are in good condition, the brushes are inspected, the copper surface underneath them is cleaned, and the tightness of the fit is assessed.

The axle should rotate freely. When repairing a hair dryer, it doesn’t hurt to lubricate the rubbing surfaces and manually work in problem areas.

Chip

The getinax backing sometimes cracks, tearing the track. Tin the damaged area and lightly cover it with solder.

Damaged capacitors swell slightly. The upper edge of the cylinder contains shallow slots; when the product breaks, the side swells, bending outward. Replace such a capacitor first if you find a characteristic defect.

Burnt out resistors turn dark. Some remain operational; it is advisable to replace such a radio element.

Thermostat

Some hair dryers are self-regulating. The effect is achieved by using a resistive divider, one arm of which is an element that responds to temperature. Further actions are determined by the parameter control implementation scheme. We recommend:

- exclude the sensor altogether by breaking the circuit and test the device’s response;

- After this, short-circuit the wires, turn them on, and see what happens.

There is a high chance of failure if the device is trained to respond only to a fixed resistance value. All that remains is to look for a circuit diagram on the Internet or draw it yourself.

Repair professional hair dryers is more complex. Design elements are often complemented by smooth controls and additional options like the Care button. Spirals are made from special alloys that, when heated, create negative ions that have a beneficial effect on hair. The technique remains the same:

- cord;

- switches and buttons;

- dust removal;

- spirals;

- motor;

- visual inspection of capacitors and resistors.

Before repairing, it is advisable to get a schematic diagram.

Industrial models are not much different from household ones. But drying your hair is not recommended. Such products are distinguished by increased resistance to dust, shock, vibration, humidity, etc. climatic factors. Home restoration industrial hair dryers It won't end well.

Electrical radio products used in household models are not suitable for use in harsh conditions. Requirements apply to wires, power cord, motor and coils.

Without exaggeration, we can say that a hair dryer lives in every home today. This softly humming accessory blows warm air, has forever entered the women's arsenal, has become an essential item and is used not only for drying hair, but also for styling and creating certain hairstyles. However, sometimes there comes a time when something inside the hair dryer begins to crunch ugly, a wave of warm breeze turns into a north wind, and an inner voice persistently tells you that an urgent repair is needed.

Design of a hair dryer

The basic design of all hair dryers can be considered identical. Any person who owns a screwdriver and basic school knowledge of electrical engineering can deal with it.

Each hair dryer consists of four main parts:

- Electric motor .

Motors come in several types - 12, 24 or 36 volts. This is done in order to protect the user. The current from the network has a voltage of 220 V and is dangerous to human health. Using an electronic circuit, the voltage is reduced, due to which the impeller that forces air to the nozzle is powered by a small DC motor, which is absolutely safe for humans.

The hair dryer is powered by an electric motor, which is supplied with reduced power for safety reasons.

- Fan. Its task is to create air flow. The body of the hair dryer is made special holes, through which the impeller sucks in air and directs it in the desired direction. Typically the propeller is made of plastic and rotates on metal rod, which serves as its axis. On one side, the axis is connected to an electric motor, on the other, it is attached to a support equipped with a sliding sleeve.

The impeller takes air through the cracks in the hair dryer body and drives it towards the nozzle

- A heating element. As a rule, this is a nichrome spiral. When current is applied, it begins to heat up and heat the passing air to the desired temperature. IN good hairdryer the spiral is designed so that the heated air does not burn the hair, i.e. its temperature does not exceed 50–60 o C.

In advanced models of hair dryers, several spirals are installed to ensure the device operates in two or three heating modes

- Electronic circuit. Serves to convert current and adjust operating modes of the device. Using the keys located on the body of the hair dryer, you can disconnect or connect the coil, increase or decrease the air flow speed.

It should be noted that the effectiveness of the device as a whole depends on the coherence of all structural components. If, for example, air channel clogged and the flow rate is slowed down, the spiral will definitely begin to overheat, and this will lead to either its failure or an increased temperature of the outgoing flow. Malfunction of the electronic circuit can lead to a voltage drop on the electric motor, as a result of which the hair dryer will not work at full capacity.

The first mention of a hair dryer is associated with the name of the French hairdresser Godenfroy. It was he who, in 1888, offered his clients to dry their hair using a patented device powered by “any heat source.” In 1908, the famous Berlin electrical engineering company AEG registered trademark“Föhn”, which translated from German meant “warm alpine breeze”. The first devices were quite bulky and heavy; the body consisted of a metal casing and weighed about 2 kg.

The prototypes of the modern hair dryer were large and heavy

Possible malfunctions of the hair dryer and their elimination

Unfortunately, equipment tends to break down. And often - at the most inopportune moment. Even expensive models produced by reputable companies can fail. The reason for this can be both non-compliance with operating rules and factors beyond human control. For example, power surges, children playing, or teething pets. Situations are different, but in any case, you shouldn’t rush to the store to buy a new device. Perhaps, having understood the cause of the breakdown more closely, you can restore the normal operation of the hair dryer without outside help, with your own hands.

The following repair information does not apply to new generation models equipped with air ionizers and infrared emitters. The design of such hair dryers is much more complicated; it is not recommended to repair them at home.

Lack of power

If problems occur, first of all you need to pay attention to the condition of the power cord and conduct a visual inspection of it. It should not get hot during operation. If there is any damage to the insulation, fractures or swelling, you need to check whether current is flowing to the device.

The hair dryer may not turn on due to damage to the cable insulation

To do this you need:

- Disassemble the case and use a voltage indicator to test the power contacts inside the hair dryer. To disassemble, you need to find and unscrew all the screws on the casing. Sometimes, in addition to them, latches are used - they must be carefully separated so as not to break the fragile plastic. On some models the screws are covered decorative plugs or stickers. In this case, carefully remove them by hooking them by the edge with a screwdriver. Before disassembling the hair dryer, do not forget to unplug it from the mains by unplugging the cord from the outlet..

After unscrewing all the screws, you need to carefully pry up the plastic plugs and disconnect the case

- Next, the wires go to the power button. You need to check that the switch moves freely and is not clogged with foreign debris or stuck together dust. If the contacts are working properly, their color will be even, without signs of charring. Overheated copper turns from yellow to dark blue, which is a sign of improper operation.

It is necessary to check all contacts for charring or discoloration, which is also a sign of improper operation of the power circuit

If damage is found, the contacts must be cleaned with a knife or sandpaper, but in no case with a damp cloth. Sometimes this is enough to restore normal operation of the device.

Plug in the device for a few seconds. In this case, the power key must be in the “Off” position. or Off. To check the presence of voltage, bring the indicator to both terminals of the button.

If there is a “phase” on the contact being tested, the indicator light will light up

The best solution to the problem of a damaged power cord is to replace it with a new one. But if it is not possible to replace the cable, you can get out of the situation by stripping the “bad” contacts and connecting them by twisting. The connection point must be carefully insulated with dielectric adhesive tape.

If you repair damage to the power cord by twisting the wires together, be sure to wrap open place electrical tape

If the problem is in the button, you need to clean it and tighten the screws securing the terminals. As a last resort, you can temporarily disable the button by connecting the wires directly. In this case, the motor will turn on immediately after connecting the cord to the outlet.

If the hair dryer control button is out of order, before purchasing new part the wires can be connected directly, however, some modes of the device will stop working

Fan doesn't work

The most common reason for a fan stopping is hair. During operation, the hair dryer pulls small hairs inside and they are wound around the propeller axis. Over time, the rotation slows down and eventually stops altogether. Obviously, it is better to periodically clean the fan and not let the situation become critical. Moreover, this is easy to do - using tweezers or a small brush to remove hairs from the impeller will not be difficult.

From the outside, you can clean the air intake holes, but in order to get to the fan, you need to disassemble the housing

The criterion for normal fan operation is the free rotation of the propeller on the engine axis.

If the situation repeats frequently, you need to carefully examine reverse side air pipe. The air intake grille may be damaged and too many foreign objects are entering through it. You can get out of this situation by sticking it on the grille mosquito net or gauze, but it must be held firmly so that it does not get sucked inside. Some models have an input air filter. It may be time to clean or replace it.

The filter is located at the back of the hair dryer, on the air intake side

Outgoing air does not heat up

The spiral is one of the most vulnerabilities all hair dryers. Despite the fact that modern heating elements are quite reliable, they are greatly influenced by the good condition of all others. structural elements. It’s good if the device has automatic shutdown of the coil when it overheats. If not, then it can burn out if, for example, the propeller is clogged or the electric motor is faulty. The first sign of excess load on the coil is the characteristic burning smell that occurs when the hair dryer is used.

The smell may persist even after the device is turned off, which indicates the need to check the serviceability of the electric motor.

Another indirect evidence of excessive heating of the coil can be heat housings. It shouldn't get hot. An abnormal increase in temperature indicates a malfunction.

If overheated, the heating coil breaks

Repairing the heating element also begins with disassembling the hair dryer. Most often, the gap is visible to the naked eye. If the damage is not total (melting of large areas or breaks in several places), it is not difficult to repair. You just need to connect the ends of the spiral again. It is best, of course, to solder them, but if you don’t have special skills, you can twist them tightly by squeezing the connection with pliers. Because nichrome wire quite thin, when turned on, a microelectric arc is formed at the junction and the ends of the spiral are welded.

It is important not only to restore the integrity of the heater, but also to determine the cause that led to overheating. Otherwise, everything will happen again very soon. If an autopsy shows that the spiral is damaged in several places, it is better to replace it entirely. In this case, you need to select a heating element from the same manufacturer as the hair dryer.

Interestingly, having originated as a hairdressing accessory, the hairdryer soon found application in such industries as construction and electrical soldering. Technical hair dryers used in many processing processes building materials, to speed up the drying and heating process adhesive compositions, heat-shrinkable tubes, etc. Today, even to ignite coals in a barbecue, a special high-temperature hair dryer is used.

Video: disassembling and repairing a Maxwell hair dryer

Problems with the electric motor

The motor is designed to rotate the fan. Usually a good hairdryer has a speed switch, with which you select the optimal air supply mode. Control occurs by changing the current supplied to the motor. For this purpose, there is a electronic circuit, which, by the way, can also fail.

The electric drive of the hair dryer fan ensures its rotation at different speeds depending on the selected operating mode

Characteristic signs of a damaged motor are a crackling sound when turned on and uneven operation. Dry discharges occur due to breakdown of winding insulation. Sometimes you can hear a hum inside the device, but the fan does not rotate. There may be a smell of burnt wiring.

A DC motor has several windings, the breakage of which is the most common cause of its failure.

Repairing an engine at home is quite difficult. This is due to its small size and the need to use special diagnostic devices. If the armature windings are burned out, then you can rewind them only using special devices. It is much easier to simply replace the damaged part. Here you just need to carefully remove the old motor and install a new one in its place.

Video: how to disassemble and repair a Scarlett hair dryer

Control unit problems

The operation of all components inside the hair dryer is interconnected. And the main coordinating link is the electronic control unit. In addition to transforming alternating current into direct current, it changes the operating modes of the motor and regulates the degree of heating of the spiral. The scheme is relatively simple, but only a specialist can understand it professionally.

The electronic circuit is located near the control buttons inside the handle

Due to voltage surges in the network, violation of operating rules, or moisture entering the electronic board, a malfunction of the unit may occur. Visually this is expressed in a change appearance details. Capacitors become deformed and swell. Resistors (resistors) darken and become charred. Connecting tracks on printed circuit board may melt and rupture. If you have spare radio components and soldering equipment, you can replace and restore the operation of the electronics. But you can replace the entire block.

To repair an electronic board, you must have special equipment and qualifications

If we talk about the procedure for diagnosing a broken device, then it should be carried out according to the principle “from simple to complex.” This means that you first need to inspect mechanical part(cord, buttons, impeller). Then - electrically, check the integrity of the connecting wires, contacts and terminals, the operation of the electric motor and the spiral. And finally, carry out an audit of the electronics - the control unit, other systems and interlocks. If inspection of the microcircuit does not give intelligible results, it is checked using a tester.

Video: diagnosing and repairing a hair dryer

How to remove a fan impeller

Often the impeller blades in hair dryers are damaged. This happens gradually as foreign debris accumulates and is drawn in by the air flow through the separator. One day the amount of foreign interference exceeds a critical state and the blades crack. This happens when the device is turned on, when the motor picks up speed and the rotational force becomes maximum.

As debris and dust accumulate inside the hair dryer, the fan blades experience increasing resistance as they rotate and finally break.

The first sign of a broken impeller is vibration. In addition, you can hear fragments of plastic cracking inside the case. If this happens, the impeller must be replaced. Needs to be removed protective cover, carefully inspect the device for attaching the propeller to the motor. IN different models connections are different. But the principle, as a rule, is the same - the impeller axis is pressed onto the electric motor drive. In most cases, it is easy to remove by carefully prying it off with a screwdriver. Sometimes this requires removing the motor and propeller from the housing and then disconnecting the blades.

All renovation work carried out only when the power is off household appliances. This is the best guarantee of safety. If the hairdryer is on warranty service, it is more expedient to solve all current problems in specialized organizations. DIY repair and improper use will void the manufacturer's warranty. Before using the device, it would be a good idea to carefully read the manufacturer’s recommendations.