How to make an infinity mirror with your own hands. Infinity mirror (Tunnel effect) LED mirrors and doors with infinity effect

Every owner wants to add a touch of originality to their interior. And everyone has their own methods for this. Some people come up with original design rooms, thanks various forms ceiling and walls, while others opt for One of these interior items that will catch the admiring glances of your guests will be a table with an infinity effect.

What is the secret?

The infinity effect is achieved through the use of LED technology. They are the ones who can decorate your home, and in some cases even change it beyond recognition. A table with an infinity effect, the photo of which is presented in this article, is a modern innovative piece of furniture that can change the idea of design of even the most notorious skeptic.

The secret of visual infinity is hidden in the use of LED backlighting, and color solutions there can be a huge variety. It is this that is built into the space between the reflective surfaces. As a rule, the top mirror is translucent so that the radiation from the LEDs is visible to others.

To control the backlight, use a special remote control or, if you made a table with an infinity effect yourself, an on/off button.

Where can the table be used?

The use of tapes with is absolutely safe for human health and environment, so the infinity table can be positioned anywhere. In addition, such lamps are famous for their durability and efficiency. A product with a tunnel effect will serve you well long term, thanks to its reliability and ease of use. This table can be seen in:

- modern apartment;

- country house;

- nightclub, bar or restaurant;

- hotel;

- office.

How to make an infinity table yourself

The price for such a piece of furniture is not encouraging, and the purchase is not always affordable for the average resident of the country. However, you can get an unusual thing if you know how to use tools. Just make a lighted table yourself.

For this you will need following materials and tools:

- boards for the table;

- mirror and glass (the latter can be replaced with a translucent mirror);

- LED strip;

- self-tapping screws;

- screwdriver

All wires are mounted in the table legs.

First of all, you need to develop a drawing, taking into account all the dimensions of the future piece of furniture. From MDF (or wooden planks), mirrors need to be made according to your calculations. Wooden templates With internal hole there should be 3 pieces, one of which is approximately 1 cm larger internal diameter. This is where the LED strip will be located. The resulting blanks need to be glued together, not forgetting to insert one mirror between the two lower templates. Then you need to carefully smooth all sides and corners.

Next you need to attach the cover. It would be better if it was removable. This will provide access to electricity. This cover for the future table can be decorated to suit your interior. You can paint it or decorate it in any other way.

In the opening of the table cover it is necessary to drill holes that are necessary for attaching the LEDs. Now you can insert the tape into this opening and secure it in a way convenient for you. The best option would be to use glue, the effectiveness of which you will be 100% sure of.

Now you should cover it all with a second mirror, translucent.

All wires are routed through the table legs. To do this, they must have a wide cross-section and through holes.

As a conclusion

To enhance the effect or make it more original, you can put absolutely any object between two mirrors. This is done to ensure that the infinity table fits perfectly into the overall concept of your room.

In addition, you can safely combine LEDs of different shades. Connecting pieces of tape is not difficult even for an inexperienced craftsman.

A similar effect can be used not only to make a table, but also to decorate doors or any other surfaces. And a table with an infinity effect, made by yourself, can be just the beginning.

Infinity Mirror- a newfangled home decoration, which is very popular due to its unusual appearance. The illusion of infinite depth, which is its “trick,” is deceptive, because the thickness of the product is only a few centimeters. How to make an infinity mirror with your own hands and is it really that difficult?

Design features with infinity effect

Such mirrors have been successfully used in the form of stylish tabletops, wall panels, and also ceiling lamps. Their feature is transparent glass on one side and a mirror surface on the other. The product is called the Gesel mirror or “Spy mirror” and is quite rarely found in stores, and if sold, it is at a steep price. Fortunately for those who want to decorate their home with it, the design is not complicated, and doing it yourself is quite possible.

How to make an infinity mirror with your own hands?

All that is needed to implement the plan is the acquisition of simple materials, a little patience and perseverance. The mirror can be any size and shape of your choice and can also have different shapes inside.

What materials will be needed?

To make it, you can take either a translucent mirror, the device with which can be turned off and used as a classic product, or mirrored on one side and transparent on the other. In general, the list of materials looks like this:

- ordinary mirror;

- sheet of window glass;

- polystyrene foam and a knife for cutting it;

- putty and spatula;

- mirror film;

- sandpaper;

- LED garland;

- glass cutter, marker, suction cup and jigsaw.

The thickness of the glass is preferably at least 4 cm, since in this case its strength will not be in doubt. To avoid dust and save energy, you can purchase it with pre-treated edges.

Step-by-step assembly instructions

The chosen design is a round infinity mirror, but any other shape is made according to the same principle. So, you will need:

- Draw a regular circle of the desired size on the glass with a marker, then use a glass cutter to make slits along its contour. Next, you need to lightly and carefully tap under the grooves until cracks appear, then put the material on a towel and break off excess pieces.

IMPORTANT. On initial stage you need to be as collected and attentive as possible, since glass is fragile and the shape of the circle can be broken. As a result, the diameter of the future mirror will significantly decrease, and the amount of time spent will increase.

ADVICE. During the process of gluing the mirror film, air bubbles may form underneath it. To avoid this, you need to smooth it out from the center to the edges with a bank card or something like that.

The final stage is assembling all components into a single structure and connecting the LED strip. In order to be able to hang a mirror on the wall, hardware store special fasteners are purchased. Before gluing them, the back wall is wiped with a solvent.

Deciding on the light source

LED strip is the best option, since after assembly the entire structure is sealed and the light source should not emit heat. Preference should be given to RGB, which will allow you to create incredible optical effects. Products with a voltage of 24 V have maximum brightness, and it is also easier for them to shine through a mirror film. In order not to waste time and nerves manipulating the LED strip, you can purchase already ready-made option, equipped with a controller, in the store. Thus, the process is simple and does not require special skills and experience - just spend a little time and effort. As a result you will get stylish mirror with an infinity effect that will decorate your home and will delight guests with its unusual appearance.

LED strip is the best option, since after assembly the entire structure is sealed and the light source should not emit heat. Preference should be given to RGB, which will allow you to create incredible optical effects. Products with a voltage of 24 V have maximum brightness, and it is also easier for them to shine through a mirror film. In order not to waste time and nerves manipulating the LED strip, you can purchase already ready-made option, equipped with a controller, in the store. Thus, the process is simple and does not require special skills and experience - just spend a little time and effort. As a result you will get stylish mirror with an infinity effect that will decorate your home and will delight guests with its unusual appearance.

The effect of endless reflections is achieved by using a mirror, mirrored translucent glass and a light source between them. Most often, such lamps are used for decorative purposes; they increase volume very well.

I designed a chandelier with a similar effect, but with the function of being the main light in the room. I ordered glass and mirror from the Glass Cutter store. A translucent mirror made from ordinary glass and mirror car film

Materials

- Mirror 500×500 and glass 500×500 with the necessary holes (ordered at the Stelorez store) ~ 950 rub.

- Mirror film (bought at the car market) 1×3m ~ 150 rub.

- Aluminum corner 40mm 4m ~ 350 RUR

- 40 pcs ~ 600 rub.

- Power supply 12V 10A with voltage regulation ~ 450 RUR

- Studs, nuts and other materials ~ 200 rub.

Characteristics

- Dimensions: 500 x 500 x 90

- Number of LEDs 32 x warm white 3W, 8 x cool white 3W

- Power consumption 14V * 600mA *10 = 84W

- Number of sections - 3 (16, 16 and 8 diodes)

- Control: three RF315MHz channels, soft start, dimming possible (did not implement), LED overheating control

Manufacturing

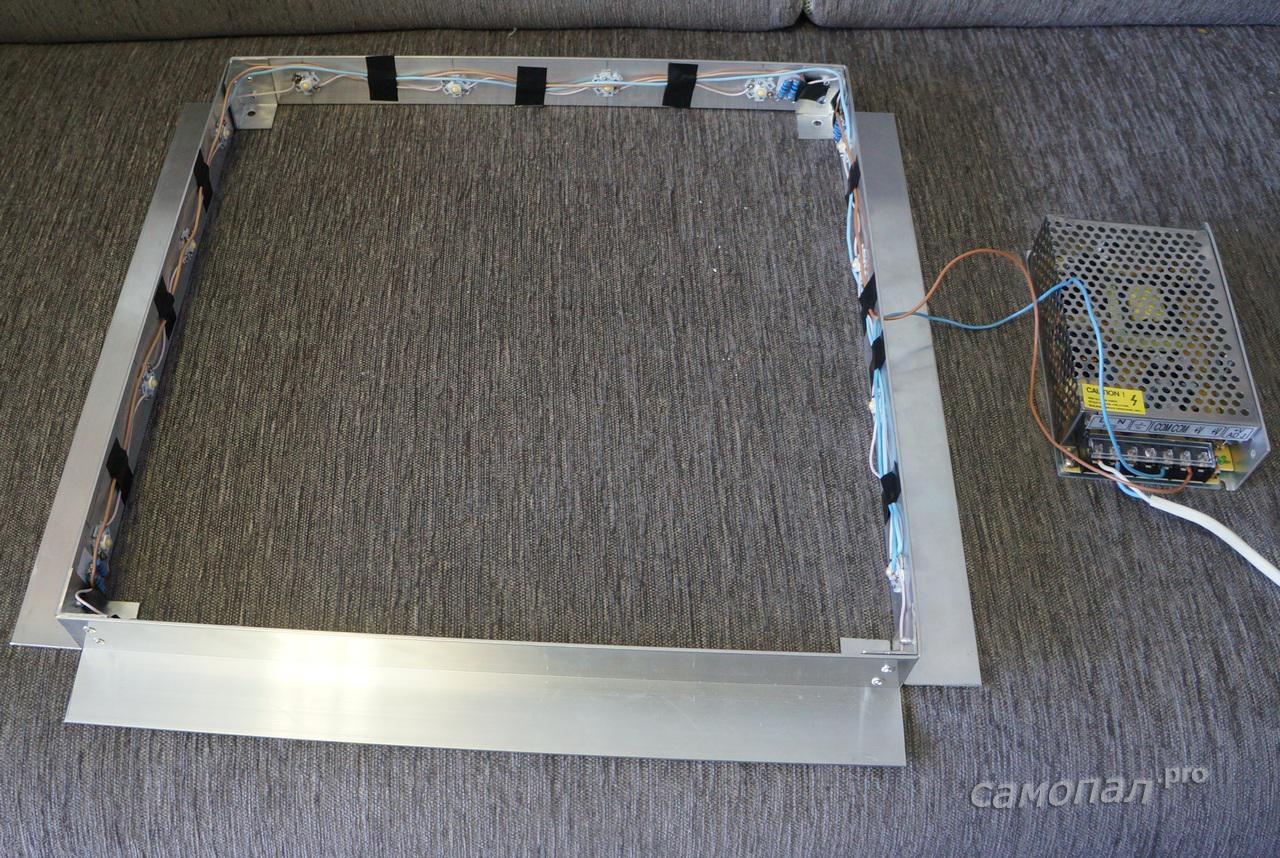

The frame is made from aluminum angle and fastened by riveting

We connect all LEDs in groups of 4 in series. We put a 1 Ohm 4W resistor on each group, then adjust the voltage to the power supplies so that the current in each group of diodes is ~ 600 mA. For what?

Firstly, I had such a power supply (I bought it with a $15 coupon on ebay)

Secondly, this solution allows you to control the brightness/power of the LEDs using PWM

The disadvantage is approximately 5 W of excess power, which is dissipated in resistors.

We assemble the second (upper) frame.

We attach LEDs to it.

We assemble the entire sandwich: bottom glass, bottom frame, mirror, top frame using studs and 5mm nuts.

We push all the wires through the holes in the mirror to the top

We install all the electrics and the control controller.

We hang it on the ceiling and connect it

We fix the wires with construction tape so as not to become an eyesore from below.

Result

There is a lot of light in the room. Only under the chandelier itself is it a bit dark due to the low light transmittance of the tint film

The infinity effect has been achieved. Guests look up and down for a long time, entering a trance :)

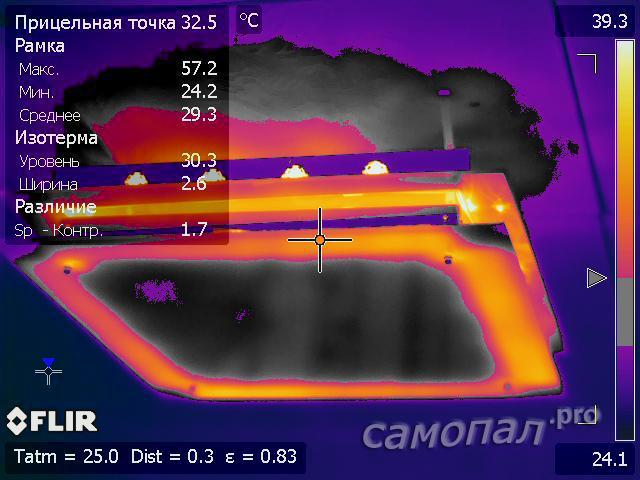

Testing

The thermal imager showed fairly uniform heating of the LEDs with maximum heating crystals 58C

The glass heats up to 35C and should not crack.

The cat wonders what time it is for good sleep wasted 😉

LED strips are an inexhaustible source of imagination for interior designers. Using them, you can create non-trivial ceiling or wall lamps, furniture lighting. We present to your attention one of the most interesting options lighting design of the room - an endless light well.

Theoretical basis of an infinity mirror (light well)

Our grandmothers used the effect of creating an illusory endless tunnel when they installed Yuletide fortune telling a candle between two mirrors. It arose due to repeated reflection of the light source from a real and imaginary mirror surface. Schematic diagram This effect is shown in the figure below.

If you want to know more about why a reflected mirror surface has the same optical properties as a real one, open a quantum physics textbook. Well, we will continue the story about how to use this effect (already with modern sources light), but for those who are ready to accept this postulate a priori.

DIY infinity mirror. Statement of the problem

So, we are faced with the task of creating a plane, when looking at which the optical effect of an endless well will appear. To do this you need:

- Light source.

- Two mirrors.

Of course, you can use your grandmother's recipe and create an open mirror system. In it, the observer's gaze is parallel to the plane of the mirrors. But this is too inconvenient due to the fact that the height of the lamp is equal to the width of the mirror. But we need a plane that does not reduce the height of the room.

Therefore, we use a closed optical system in which the viewing direction is perpendicular to the plane of the mirrors. Only one of them should transmit part of the photon flux from the light source. Otherwise we won't see anything.

To get the desired optical effect we need:

- Classic mirror with one-way reflection.

- Glass with a partial mirror effect.

- Design that holds mirrors at a distance of no more than 2 cm from each other.

- Light source.

Implementation of the design

This design can be implemented in different ways. It all depends on what's available home handyman materials. Below is one possible solution.

Mirrors

Everything is clear with a classic mirror, you need to buy it suitable size or trim the existing one. What to make translucent from? The best option– glass 4 mm thick, covered with automotive tint film. Choose one that transmits at least 50 percent of light radiation.

Frame

For the frame holding the mirror system, it is better to use wooden blocks with a side of 2 cm. No tricky spikes are required for articulation. To securely stick them to the surface of the absolute mirror, use silicone sealant. Transparent is better.

In the rack frame you must first drill a hole parallel to the plane of the mirrors. The wires supplying the light source are routed through it. The slats are glued one at a time. At the same time, they are aligned along the outer edges of the mirror.

Light source

After assembly, the cavity of the optical system becomes sealed and non-ventilated. Therefore, the light source can only be one that does not emit heat. The best option is LED strip. It is better to choose RGB, which will allow you to create additional optical effects. If possible, use those whose operating voltage rating is 24 volts. They are brighter and easier to penetrate through the mirror film.

Assembly

The assembly process is simple. If all of the above elements are at hand, then you only need to be careful.

- Glue the frame slats with silicone sealant to the mirror on the side of the reflective surface.

- Pin on inner surface frame, an RGB LED strip, lead the power cord through a hole pre-drilled in the frame rail.

- Cut the mirror film to the width of the frame.

- Apply silicone sealant to the frame and place glass with a mirror film on top (mirror surface inward).

Now it remains to decide what to do with the ends to cover the wooden frame.

- If everything is done carefully and the frame slats are planed, then the ends are painted.

- Use an aluminum U-shaped profile - great solution for design in Hi-Tech style.

- Apply plastic cable channel without cover.

The same silicone sealant is suitable for securing the profiles.

Belt design options

If you place RGB- LED strip along the perimeter of the holding frame, then visual effect will consist of repeating luminous rows. It's interesting, but too simple.

Show your imagination and glue two or three geometric shapes made from the same slats onto the mirror along with the frame. Glue the LED strip around the perimeter of the inserts. Just make sure that its length is a multiple of the integer value of the distance between the mounting points along which the tape can be cut. The power wire will have to be routed through the mirror. To do this, it is drilled with a diamond-coated drill.

Connecting LED strip

If the RGB strip is connected directly to the power supply, it glows white. Color effects are possible when connected via a controller. This control device works in tandem with a remote control. But if you want to see color music, you need to choose models that are compatible with a computer.

It is better to choose a power supply whose power is two (at least) times greater than the power consumption of the tape. This will allow you to enjoy the lighting effects indefinitely without fear of overheating.

Hi all!

I’m new here myself, I finally decided to register and this is my first post, so I apologize if anything is wrong.

In this post I will tell you how to do mirror with infinity effect at home, I would like to immediately note that it is not made from a wooden frame or some other rubbish, but an adequate, presentable mirror that will look good and can be made at home.

At the end, I will write down how much all the materials cost and what the cost of such a mirror is.

What is required for production

To begin with, we will need two glasses measuring 50 x 50 cm and 4 mm thick. If you bought glass without edge treatment, then sharp edges and corners can be treated with regular sandpaper. We will also need architectural mirror film up to 15% light transmission, in my case there was a film with 8% light transmission.Manufacturing

We cover one glass with film on one side as shown in the photo, this will be the front glass of the mirror.

We cover the second glass with film on both sides, but on one side we retreat 1.3 cm from the edge and cut the film along the contour of the glass along a ruler as in the photo, this will be the rear glass of the mirror.

We will need this indentation for fastening aluminum profile, but before that the profile needs to be cut into equal 4 parts of 47 cm each, I bought a 2-meter profile measuring 2 x 1.5 cm and cut it into 4 parts.

It also needs to be processed sharp corners profile with a file.

Then we treat (wipe) the edges of the glass and the profile with white spirit and let it dry.

Next we need a two-component adhesive for glass and metal.

We lubricate one stack of each profile with it as in the photo.

And we glue the profile to the rear glass of our mirror on the previously freed part of the glass from the film in such a way that the hollow part of the profile looks outward as in the photo:

Next, we make a hole for the passage of the LED strip.

I prepared an LED strip with a controller in advance, I won’t go into detail on this, since the post turned out to be too long, and you can buy a ready-made strip with a controller and not solder anything.

We insert and glue the tape along the inside of the frame of our mirror.

Next, we will need a special double-sided tape for fastening mirrors and glass, sold at a hardware store.

We glue it along the top of the profile and press the front glass.

I prefer the tape because in the event of some kind of malfunction of the diodes, I could crawl with a stationery knife between the top cover of the mirror and the profile, cut the tape and eliminate all the faults, which cannot be done in the case of glue.

The mirror is almost ready, all that remains is to attach it to the wall, this is done using mirror fasteners, also sold at a hardware store. We cut the film along the contour of the fasteners from the back wall of the mirror and treat the glass with white spirit

Fasteners, with reverse side It has a strong adhesive area.

We process the area.

We press the fasteners onto the mirror.