The thread is trapezoidal left. Threaded connections. Application of trapezoidal thread

Profiles and thread sizes

(GOST 9484-81)The standard applies to trapezoidal threads and establishes the profiles and dimensions of its elements.

MAIN PROFILE

Example symbol trapezoidal single-start thread with a nominal diameter of 20 mm, a pitch of 4 mm and an average diameter tolerance of 7e:

Tg 20 x 4 -7e

NOMINAL PROFILES

outdoor and internal thread

h 3 - profile height external thread; H 4 - internal thread profile height; d 3 - inner diameter external thread; D 4 - outside diameter internal thread; R 1 - rounding radius at the top of the external thread; R 2 - radius of torsion in the root of the external and internal threads; a c is the gap at the top of the thread.

DIAMETERS AND STEPS

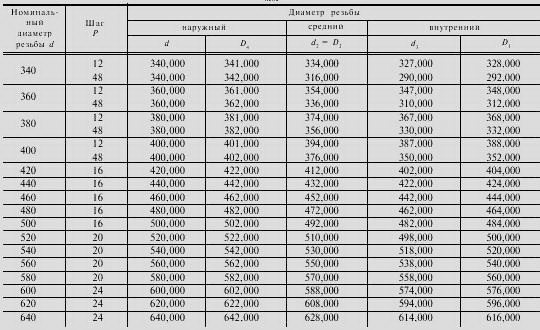

trapezoidal single-start thread according to GOST 24737-81

Preferred diameters and pitches are specified in GOST 24738-81. Numeric values tolerances of diameters and pitches - according to GOST 9562-81

DIAMETERS AND STEPS

trapezoidal multi-start thread according to GOST 24739-81

Notes:

1. Steps outlined in a box are preferred steps.

2. The steps indicated in parentheses are not recommended for use when developing new designs.

3. Threads with a stroke value marked * have a lead angle of more than 10 o. For these threads, the deviation of the profile shape must be taken into account during manufacturing.

4. In technically and economically justified cases, it is allowed to use other values of nominal thread diameters in accordance with GOST 24738-81.

5. When choosing thread diameters, you should prefer the first row to the second.

An example of a symbol for a trapezoidal multi-start thread with a nominal diameter of 20 mm, a stroke value of 8 mm, a pitch of 4 mm and a tolerance range of 8e:

Tg 20-8 (P4) - 8e

The same, left:

Tg 20-8 (P4) LH - 8е

The make-up length, if different from the thread length, is indicated in millimeters at the end of the thread designation, for example:

Tg 20-8 (P4) LH - 8е - 180

Numerical values of make-up lengths related to groups N and L are in accordance with GOST 9562-81.

The fit in a threaded connection is indicated by a fraction

Tg 20-8 (P4) LH - 8Н/8е - 180

Numerical values of tolerances of diameters d and D 1 - according to GOST 9562-81.

Numerical values of tolerances for diameters d 2, d 3 and D 2 - according to GOST 24739-81.

Application of trapezoidal thread

Trapezoidal thread The screw is a running thread with a relatively high friction force; it is self-braking. The advantage for lifting technologies is that in the resting position it does not require additional fixation.

Trapezoidal threads are used to convert rotary motion into linear motion and are used primarily for linear motion. It also finds its use as a lead screw in lathes or as a drive thread for screw press tables or bridges of vehicles.

Application examples for trapezoidal spindle threads:

Feed movements on machine tools (e.g. adjusting and lead screws);

- movement on the manipulator;

- regulation of movement on lifting mechanisms and forklifts;

- movement of the shutter when locking injection molding machines;

- moving movement on assembly containers;

- vertical movement when working with the press.

Related documents:

GOST 3469-91 - Microscopes. Lens thread. Dimensions

GOST 4608-81 - Metric thread. Preference fits

GOST 5359-77 - Eyepiece thread for optical instruments. Profile and dimensions

GOST 6042-83 - Edison round thread. Profiles, dimensions and limits

GOST 6111-52 - Conical inch thread with a profile angle of 60 degrees

GOST 6211-81 - Tapered pipe thread

GOST 6357-81 - Cylindrical pipe thread

GOST 8762-75 - Round thread with a diameter of 40 mm for gas masks and calibers for it. Main Dimensions

GOST 9000-81 - Metric threads for diameters less than 1 mm. Tolerances

GOST 9484-81 - Trapezoidal thread. Profiles

GOST 9562-81 - Single-start trapezoidal thread. Tolerances

GOST 9909-81: Tapered thread of valves and gas cylinders

GOST 10177-82 - Persistent thread. Profile and main dimensions

GOST 11708-82 - Thread. Terms and Definitions

GOST 11709-81 - Metric thread for plastic parts

GOST 13535-87 - Reinforced thrust thread 45 degrees

GOST 13536-68 - Round thread for sanitary fittings. Profile, main dimensions, tolerances

GOST 16093-2004 - Metric thread. Tolerances. Landings with clearance

GOST 16967-81 - Metric threads for instrument making. Diameters and pitches

GOST 24737-81 - Single-start trapezoidal thread. Main Dimensions

GOST 24739-81 - Multi-start trapezoidal thread

GOST 25096-82 - Persistent thread. Tolerances

GOST 25229-82 - Metric tapered thread

GOST 28487-90: Conical locking threads for drill string elements. Profile. Dimensions. Tolerances

Trapezoidal thread is widely used for manufacturing different screws, which serve for various production equipment. For example, for machines lifting devices, presses Such a thread has the form of an isosceles trapezoid, and the profile angle can have different meanings: 15, 24, 30, 40°. During the operation of a screw on which a trapezoidal thread is cut, frictional forces appear naturally caused. That is, due to the presence of lubricant, surface roughness, and also the profile angle.

Types of thread

Today there are the following types:

- Metric. It serves to secure several elements. The cutting conditions are set in regulatory documentation. The profile is a triangle with equilateral angles. This indicator is 60°. Screws with metric threads are made in small and large pitches. The first type is used to secure thin-sheet elements to create increased tightness. This type of connection can be found in precision optical instruments.

- Conical. It is manufactured in the same way as the previous type, but twisting is done to a depth of 0.8 mm.

- Inch. To date, there is no regulatory document that would indicate thread sizes. Inch threads are used for repairs various equipment. As a rule, these are old instruments and devices. Its main indicators are the outer diameter and pitch.

- Pipe cylindrical. This type is an isosceles triangle, the upper angle of which is 55°. This internal thread is used to connect pipelines, as well as parts made of thin sheet material. It is recommended when there are special requirements for the tightness of the connection.

- Pipe conical. The internal thread must comply with all regulatory requirements. The sizes are completely standardized. It is used to connect various types of pipelines.

- Persistent. This type is an unequal trapezoid, where one side is inclined by 3° and the other by 30°. The first side is the working side. The shape of the profile, as well as the diameter of the steps, are determined regulatory documents. In accordance with them, threads are made with a diameter from 10 to 600 mm, with a maximum pitch value of 24 mm. They are used where increased holding forces are required.

- Round. The thread profile consists of various arcs connected to each other by straight lines. The profile angle is 30°. This type of thread is used for those connections that are exposed to aggressive environments.

- Rectangular. It is not supported by any regulatory documents. Its main advantage is high efficiency. Compared to the trapezoidal type, it is less durable, and also causes many incomprehensible moments during its production. The main place of application is jacks and different kinds screws

- Trapezoidal. It has the shape of an isosceles trapezoid with a profile angle of 30°. Trapezoidal thread, the dimensions of which are fixed in the documentation, is used to connect various elements production equipment.

Manufacturing conditions

Compared to other types, trapezoidal threads are much easier to manufacture.

That is why it is more often used in various fields. The most popular is the trapezoidal thread screw, which has a profile angle of 30°. The production technology is very similar to that used for cutting rectangular threads. But there are still significant differences regarding the accuracy and cleanliness of manufacturing. Cutting a trapezoidal thread is no different from the same procedure with a rectangular thread. On this moment There are several such methods.

Making a screw with one cutter

Single-start trapezoidal threads are manufactured as follows:

- the workpiece is prepared and channels for sharpening are created;

- The cutter is sharpened according to a special prepared template;

- The sharpened element is installed and secured. It should be positioned so that the centers coincide and are parallel to the cutting axis;

- the equipment is turned on and the workpiece is fed for thread cutting;

- the finished part is checked in accordance with the finished template.

Three-cut slicing

This method is as follows:

- the workpiece is prepared;

- three incisors are sharpened - straight, narrow and profile;

- The prepared elements are installed and secured. They can be located either perpendicular or parallel to the thread axis. It all depends on the angle of inclination.

Common production method

It is in production that cutting trapezoidal threads takes place in this way:

- working equipment is checked and adjusted;

- thanks to the slotted cutter, small indentations are made on the screw;

- using a narrow slotted element, the screw is cut to a certain diameter;

- using a profile slotted element, it is made final production trapezoidal thread;

- the finished part is checked in accordance with ready-made templates.

Trapezoidal thread: dimensions

As stated earlier, this type The thread has the shape of a trapezoid, in which the angle between the sides can have different values. All main dimensions are set in accordance with GOST.

For a single-start type, trapezoidal thread (dimensions - GOST 9481-81) has dimensions and pitches various diameters- from 10 to 640 mm. In addition, it can be multi-entry, as well as twisted to the left or right side. These indicators are standardized by GOST 24738-81.

Where is it used?

For the functioning of any element, such as a machine or mechanism, it is necessary to perform mandatory condition: Rotational movements must be converted into translational ones.

This principle is used for the manufacture of various machines, devices, and control systems used in the industrial sector.

Advantages of thread

The efficiency of converting rotational movements into translational ones is carried out using a nut and a screw. Even though these parts look simple, they require care when making them. It is on these parts that performance and reliability depend not only constituent elements, but also all working equipment.

Features of multi-start thread

To endow the screw strength characteristics and increase its stroke using a multi-start trapezoidal thread. In this case, all parameters, such as the height of the thread, its diameter, are absolutely the same, with a single-start appearance. The only difference is the number of moves per step. For example, three-start threads have a stroke three times their pitch. All this can be seen in the pictures.

Let us give an example so that this type becomes clear to every person. Everyone uses regular lids for canning vegetables and fruits. To open them you need to make a minimum of effort. When using large diameter cylinders, it is much more difficult to get into the grooves of a single-thread thread. That is why multi-pass ones are used.

This type of carving can be determined visually, just look at the drawing.

You can see exactly how many turns go from the beginning of the screw. Multi-pass threads are manufactured using complex technologies and, accordingly, are more expensive.

Other advantages

Trapezoidal connections have many positive qualities. That is why they are used in various manufacturing industries. The most common field is mechanical engineering. So, their advantages include the following:

- ability to assemble and disassemble various devices unlimited number of times;

- convenient disassembly and assembly process;

- reliability of the threaded connection;

- easy manufacturing process;

- independent regulation of compression force;

- production of parts in various designs.

Disadvantages of connections

There are not many negative aspects to this type of connection. One of them is the occurrence of high stress in the depressions. In addition, they cannot be used in devices and mechanisms that have high vibration, since the screws can unscrew on their own, which is not a good sign.

Therefore, it is necessary to monitor this, and if such a situation arises, correct the position of the screws.

Quality such as cost can be attributed to both positive and negative aspects.

Single-stroke threads cost significantly less than multi-stroke threads. Here everyone chooses according to personal preferences. Many design organizations use multi-pass threads, as they are reliable and durable.

So, we found out what this type of connection is, such as a trapezoidal thread, its dimensions, advantages and disadvantages.

In mechanisms where it is necessary to convert rotation into translational motion, they are used. In addition to its transformative function, this thread can withstand increased loads. This is a popular type of thread in important nodes mechanisms, machines. You can observe the principle of operation of this thread when turning screws, when the rotation of the screw causes it to move in a linear direction. The force applied to transform the movement depends on the profile angle, thread pitch and part material.

The name carving comes from its resemblance to a trapezoid.

Contact phone number: whatsapp.

Main characteristics of trapezoidal thread

The trapezoidal shape is formed by the angle of the thread profile. In this type, the profile angle can range from 15 to 40 degrees.

In the working process, threads may cause excessive friction. This factor is influenced by the profile angle, type of lubricant and material used. Radial clearances in trapezoidal threads can be identified by placing the thread in the middle of the diameter.

Trapezoidal threads are quite simple to manufacture. In most cases, the profile angle is set to 30 degrees. The quality of the thread depends largely on the accuracy of the workpiece used, as well as the material.

Methods for cutting trapezoidal threads

The production of this type of carving can be divided into two categories - one cutter and three cutters.

As an example, consider the following designation: Tr 26 × 4 LH – trapezoidal thread, single-start, with a diameter of 26 and a pitch of 4, left-handed.

GOST 9484-81 is used as the main standard.

GOST 9484 – 81

Trapezoidal thread has a profile with an angle of 30°. Thread pitch measured in millimeters.

Trapezoidal thread used in machine units to convert rotational motion into translational motion, for example: machine lead screws, press power screws, lifting screws, etc. Threads of this type can withstand significant loads.

Trapezoidal thread indicated by letters Tr- English trapezoidal:

- Tr 28 × 5- diameter 28mm pitch 5mm

- Tr 28 × 5 LH- diameter 28mm pitch 5mm left thread

- Tr 20 × 8 (P4)- diameter 20 mm, pitch 4 mm and stroke 8 mm multi-start thread

- Tr 20 × 8 (P4) LH- diameter 20 mm, pitch 4 mm and stroke 8 mm multi-start thread left

d– outer diameter of the external thread (screw)

D– outer diameter of the internal thread (nut)

d 2 – average diameter external thread

D 2– average diameter of internal thread

d 1– internal diameter of external thread

D 1– internal diameter of internal thread

P– thread pitch

H– height of the original triangle

H 1– working height of the profile

| Trapezoidal thread | |||

| Thread diameters d | Step | ||

|---|---|---|---|

| Row 1 | Row 2 | ||

| 10 | 1.5; 2 | ||

| 11 | 2 ; 3 | ||

| 12 | 2; 3 | ||

| 14 | 2; 3 | ||

| 16 | 2; 4 | ||

| 18 | 2; 4 | ||

| 20 | 2; 4 | ||

| 22 | 3; 5 ; 8 | ||

| 24 | 3; 5 ; 8 | ||

| 26 | 3; 5 ; 8 | ||

| 28 | 3; 5 ; 8 | ||

| 30 | 3; 6 ; 10 | ||

| 32 | 3; 6 ; 10 | ||

| 34 | 3; 6 ; 10 | ||

| 36 | 3; 6 ; 10 | ||

| 38 | 3; 7 ; 10 | ||

| 40 | 3; 7 ; 10 | ||

| 42 | 3; 7 ; 10 | ||

| 44 | 3; 7 ; 12 | ||

| 46 | 3; 8 ; 12 | ||

| 48 | 3; 8 ; 12 | ||

| 50 | 3; 8 ; 12 | ||

| 52 | 3; 8 ; 12 | ||

| 55 | 3; 9 ; 14 | ||

| 60 | 3; 9 ; 14 | ||

| 65 | 4; 10 ; 16 | ||

| 70 | 4; 10 ; 16 | ||

| 75 | 4; 10 ; 16 | ||

| 80 | 4; 10 ; 16 | ||

| 85 | 4; 12 ; 18 | ||

| 90 | 4; 12 ; 18 | ||

| 95 | 4; 12 ; 18 | ||

| 100 | 4; 12 ; 20 | ||

| 110 | 4; 12 ; 20 | ||

| 1. When choosing a thread, priority is given to the first row. 2. The thread pitch highlighted in color is preferred. |

|||

The functioning of the drives of many machines, equipment and mechanisms is based on a process such as the transformation of rotational motion into translational motion. This principle applies, for example, to drives of measuring machines and equipment, control systems for gates and valves, scanning tables, robots and machine tools.

In order to effectively convert the rotation of one part into the translational movement of another part, a pair of screws and nuts is most often used. Such gears are products that have general machine-building applications, and it should be noted that the performance, functionality and reliability of the equipment largely depends on how well they are designed and manufactured. components which they are.

Due to the fact that the screw-nut transmissions have increased smoothness of engagement, they are almost completely silent during operation. Their design is relatively simple, and one of the undoubted advantages is that their use allows for significant gains in strength. By and large, the screw-nut transmission from a technical point of view is no different from a conventional threaded connection, however, since they are used to transmit movement, they are made in such a way that the friction force in the thread is minimal.

In principle, this can be achieved by using a rectangular thread, but it also has its disadvantages. For example, it cannot be cut on standard threading machines, and compared to trapezoidal threads, it has much lower strength. These factors lead to the fact that in screw-nut transmissions, rectangular threads are used quite rarely. The most common among them trapezoidal thread, having large, medium and fine pitch, as well as persistent thread.

Most often in screw-nut gears you can find trapezoidal thread, having an average step. It is used, but with small steps, when it is necessary to ensure small movement, and with large steps – when the device is operated in difficult conditions. In addition, thanks to the profile features, trapezoidal thread can be successfully used in mechanisms that require reverse movement. Such threads can be single- or multi-start, right-handed or left-handed.

Materials used in screw-nut transmissionThe main requirements for those materials that are used in screw-nut transmissions are wear resistance, strength and good machinability. As for those screws that are not subject to hardening, they are made of steel A50, St50 And St45, and those that are subjected to hardening are made of steels 40ХГ, 40X, U65, U10. Nuts are usually made of bronze BrOTsS-6-6-3 or Brofyu-1.